Flexible composite membrane with optical limiting characteristic and preparing method thereof

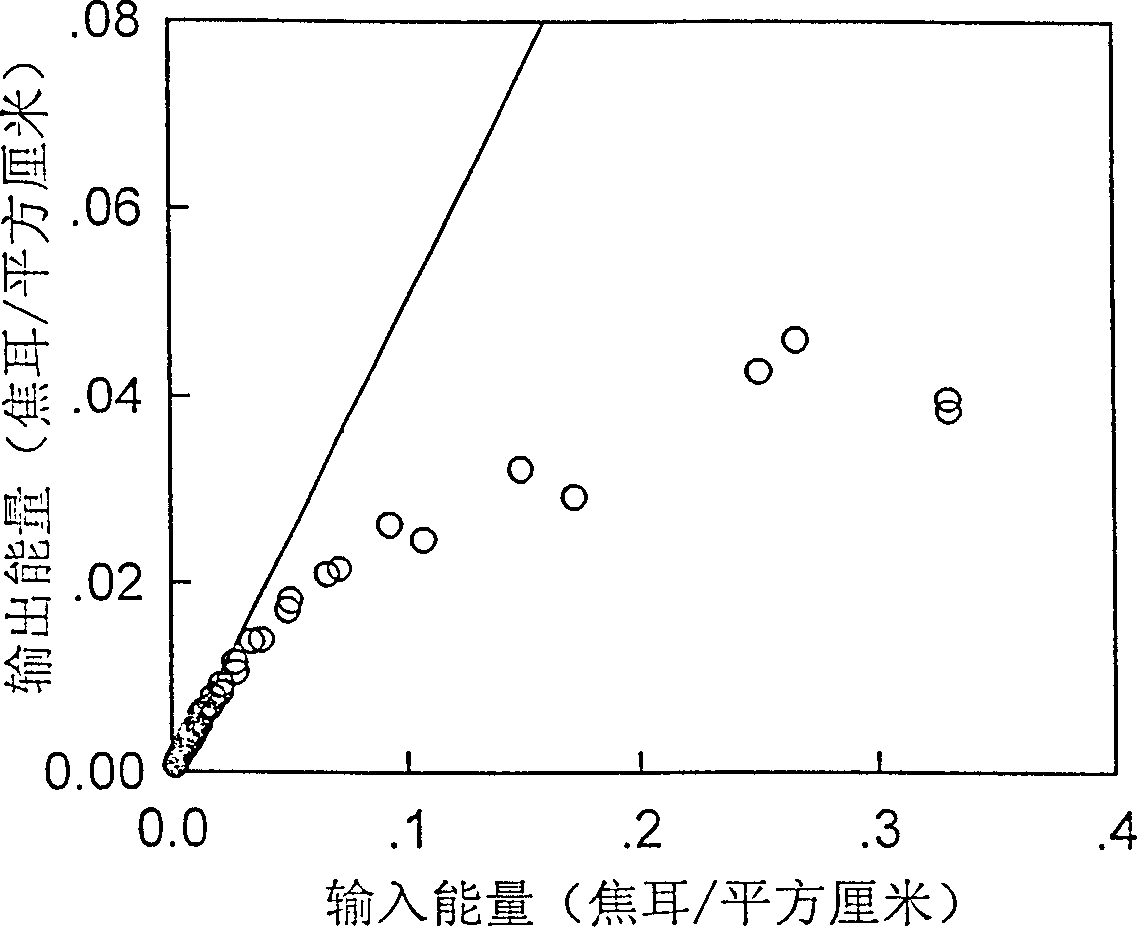

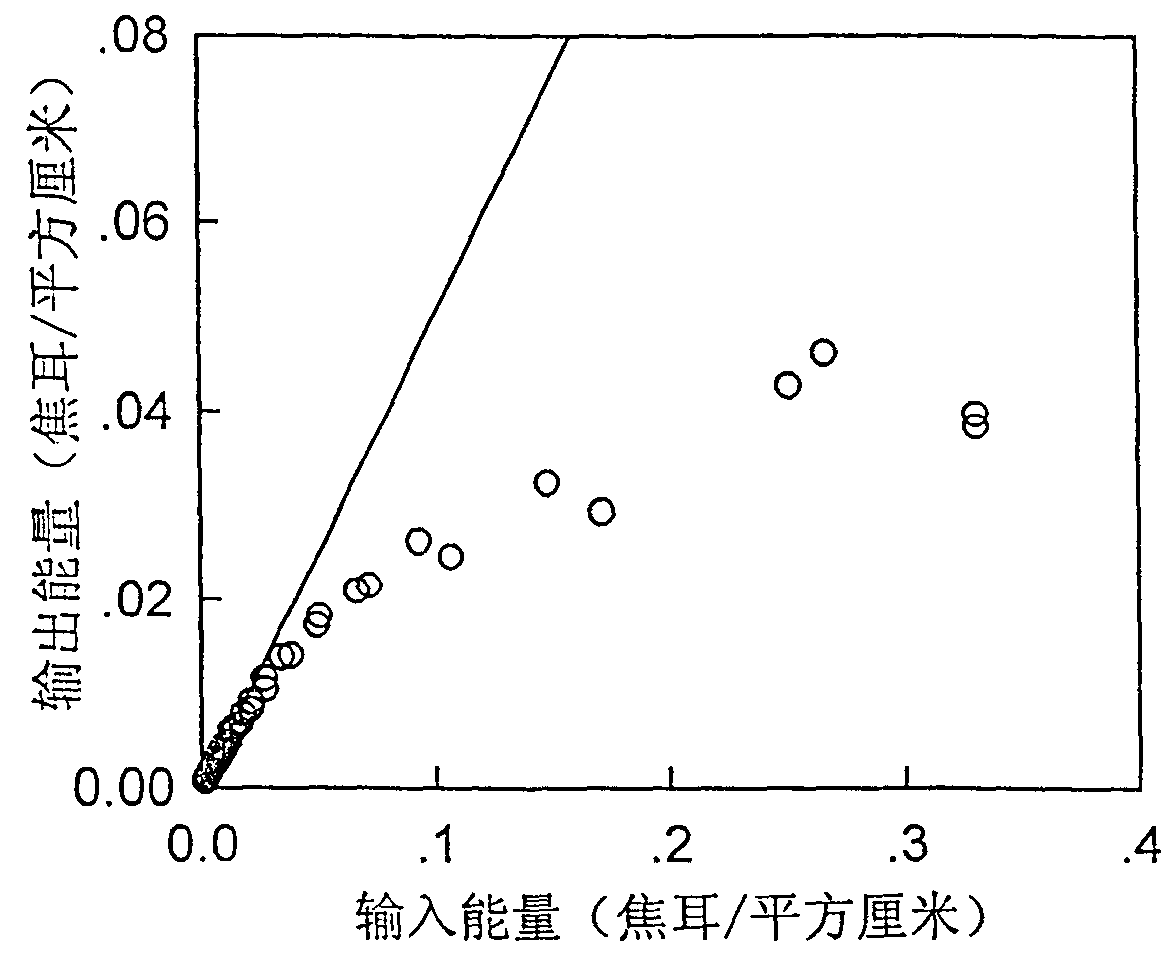

A composite film and optical limiting technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of poor flexibility and optical limiting performance of solid-state fullerene optical limiting materials and devices and other problems, to achieve the effect of good light limiting characteristics and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

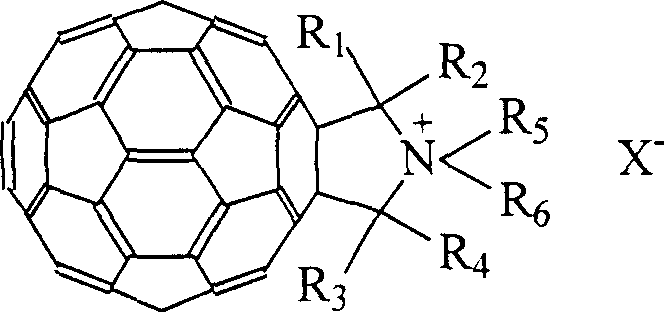

[0038][60] fullerene pyrrolidine derivative A1: fullerene = [60] fullerene, R 1 = R 2 = R 3 = Hydrogen, R 4 = 4-phenol group, R 5 = methyl, add 5 mg of [60] fullerene pyrrolidine derivative A1, add 5 ml of methyl iodide to make a suspension, stir at room temperature for 2 days, remove excess methyl iodide; add 5 ml of toluene, stir, and dissolve the precipitated The solid precipitate was separated by centrifugation, and this step was repeated 4 times; the quaternary ammonium salt B1 of [60]fullerene pyrrolidine derivative A1 was obtained.

[0039] The quaternary ammonium salt B1 of the prepared fullerene pyrrolidine derivative was added to 5ml of methanol and 20mg of vacuum-dried Nafion film, stirred at room temperature for 0.2 hours, and the transmittance of the film was measured at 532nm in a UV-visible spectrophotometer to be 45 %, and then the film was taken out; the fullerene derivatives that might be adsorbed on the film surface were washed away with methanol; and dr...

Embodiment 2

[0041] [60] fullerene pyrrolidine derivative A2: fullerene = [60] fullerene, R 1 = R 3 = Hydrogen, R 2 = R 5 = methyl, R 4 =4-(3-octyloxy)phenyl, add 5 mg of [60]fullerene pyrrolidine derivative A2 to 5 ml of methyl iodide to make a suspension, stir at room temperature for 2 days, and remove excess methyl iodide; Then add 5ml of toluene, stir, centrifuge the precipitated solid precipitate, repeat this step 4 times; obtain quaternary ammonium salt B2 of [60] fullerene pyrrolidine derivative A2.

[0042] The quaternary ammonium salt B2 of the prepared fullerene pyrrolidine derivative was added to 5ml of ethanol, 20mg of vacuum-dried Nafion film, stirred at room temperature for 0.3 hours, and the transmittance of the film was measured at 532nm in an ultraviolet-visible spectrophotometer. %, and then the film was taken out; the fullerene derivatives that might be adsorbed on the film surface were washed away with ethanol; and dried to obtain the fullerene-Nafion nanocomposite ...

Embodiment 3

[0044] [70] fullerene pyrrolidine derivative A3: fullerene = [70] fullerene, R 1 = R 2 = R 3 = Hydrogen, R 4 = 4-phenol group, R 5 =Methyl, add 5ml of methyl iodide to [70]fullerene pyrrolidine derivative A3 5mg, add 5ml of methyl iodide to make a suspension, stir at room temperature for 2 days, remove excess methyl iodide; then add 5ml of toluene, stir, and precipitate The solid precipitate was centrifuged, and this step was repeated 4 times; the quaternary ammonium salt B3 of [70]fullerene pyrrolidine derivative A3 was obtained.

[0045] With the prepared quaternary ammonium salt B3 of fullerene pyrrolidine derivatives, add 2.5ml methanol and 2.5ml ethanol, 20mg vacuum-dried Nafion film, stir at room temperature for 2 hours, and measure the film density at 532nm in a UV-visible spectrophotometer. The transmittance was 55%, and then the membrane was taken out; the fullerene derivatives that might be adsorbed on the surface of the membrane were washed away with ethanol; an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com