Axial-flow ventilating machine for transformer

A technology for axial flow fans and transformers, applied in axial flow pumps, transformer/inductor cooling, machines/engines, etc., can solve problems such as difficulty in achieving transformer axial flow, affecting fan performance, and large fan flow. Achieve excellent aerodynamic performance, wide application range and flat performance curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

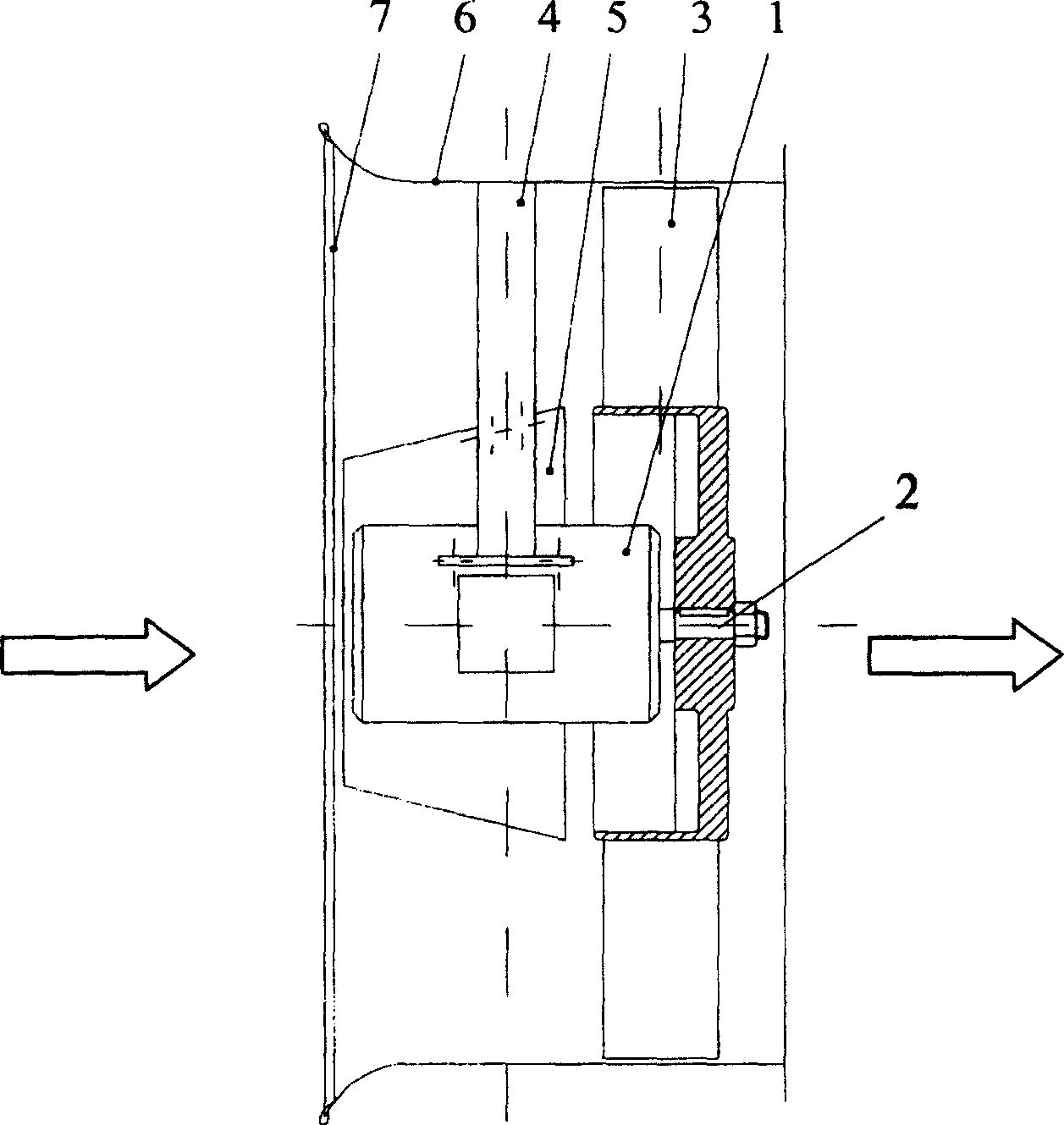

[0018] figure 1 Shown is a schematic diagram of the overall structure of the preferred embodiment 1 of the present invention, and the airflow direction is from left to right. The motor 1 is located at the inlet end of the fan, and the motor shaft 2 is connected with the impeller 3 to drive the impeller 3 to rotate. Motor 1 is supported by support 4, and the outside is covered with shroud 5, and shroud 5 is a hollow conical cylinder, and the taper of cone is 13 °, and length is 236 millimeters, and the diameter of bottom surface is equal to the diameter of wheel hub. The casing 6 is cylindrical with a diameter of 910 mm, and is slightly bell-shaped at the inlet end, so that the airflow can smoothly enter the flow channel of the fan. A protective cover 7 is designed on the face of the inlet end of the fan to prevent debris from entering the fan flow path and impacting the blades.

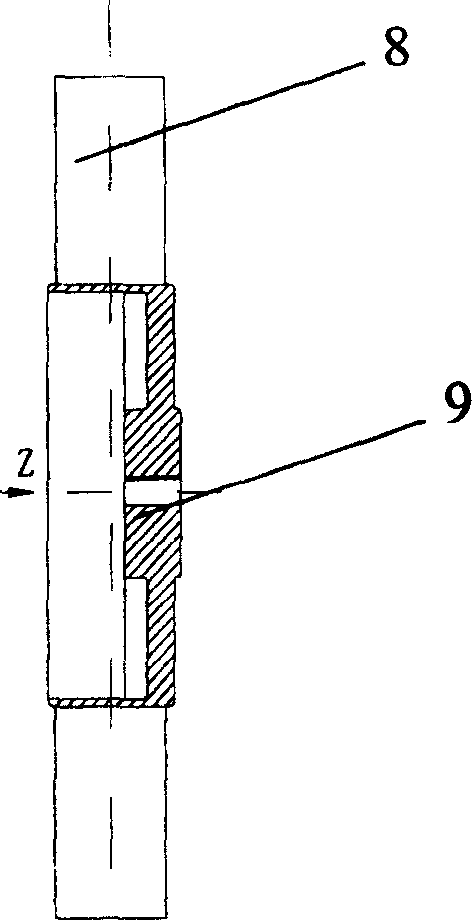

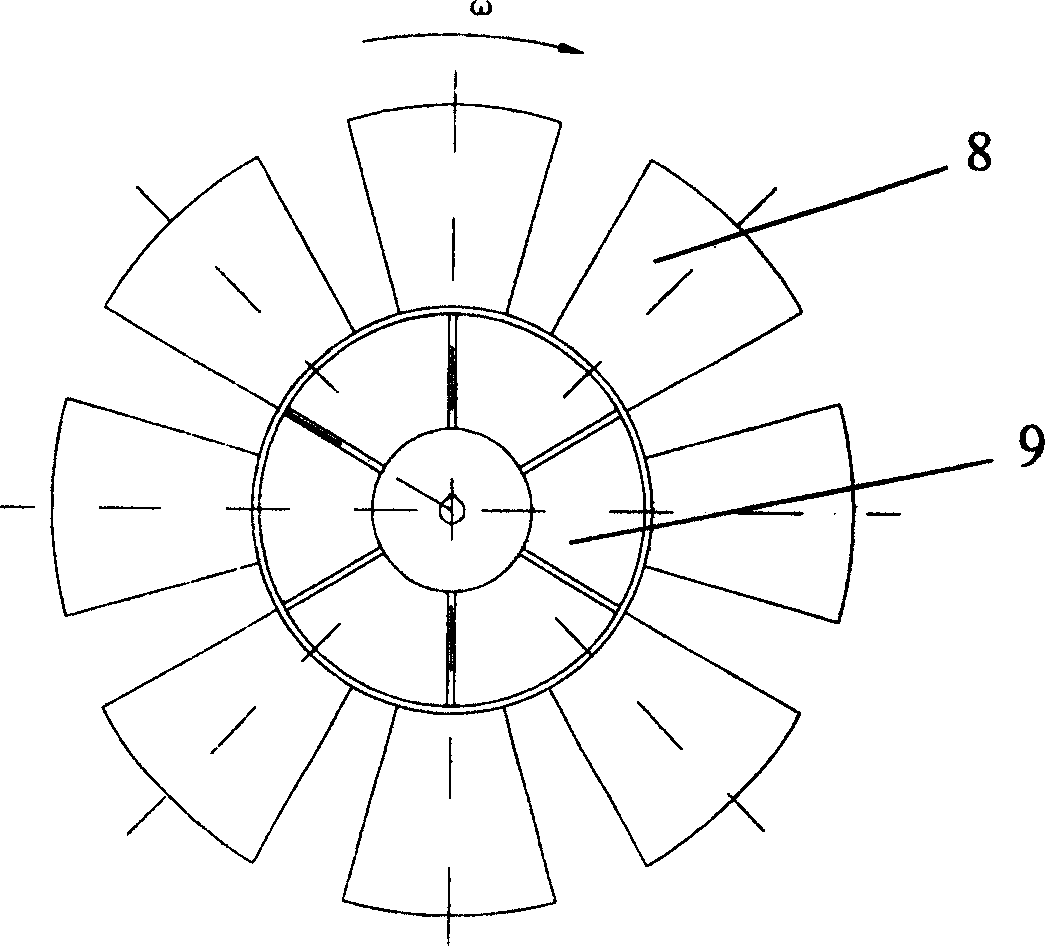

[0019] figure 2 , 3 Shown are a side view and a front view of the partial structure of the im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com