Assembly and method for cutting strands formed by thermoplastics filaments

A technology of plastic material and string, which can be used in the direction of forming non-bundle, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of complex system and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

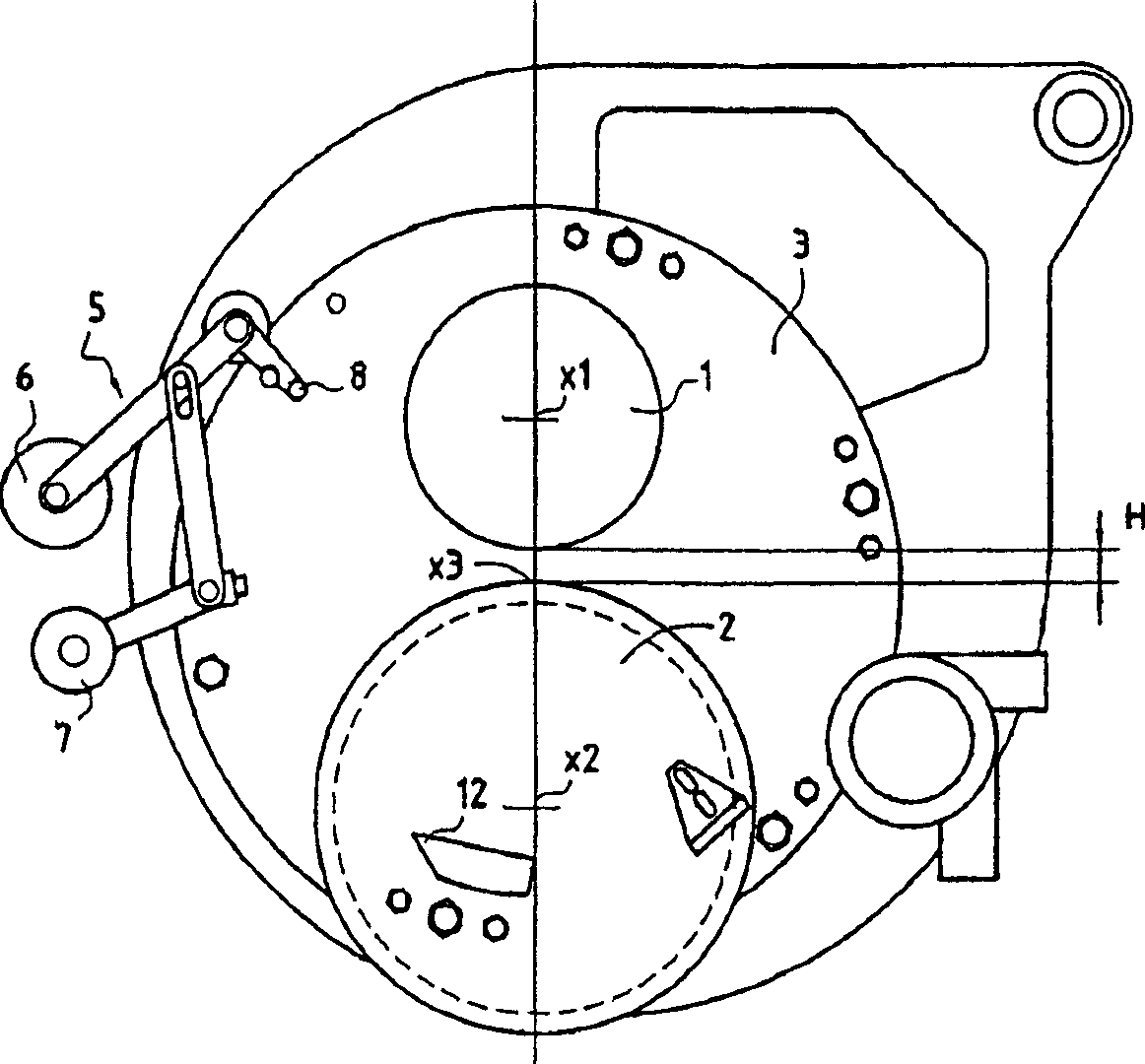

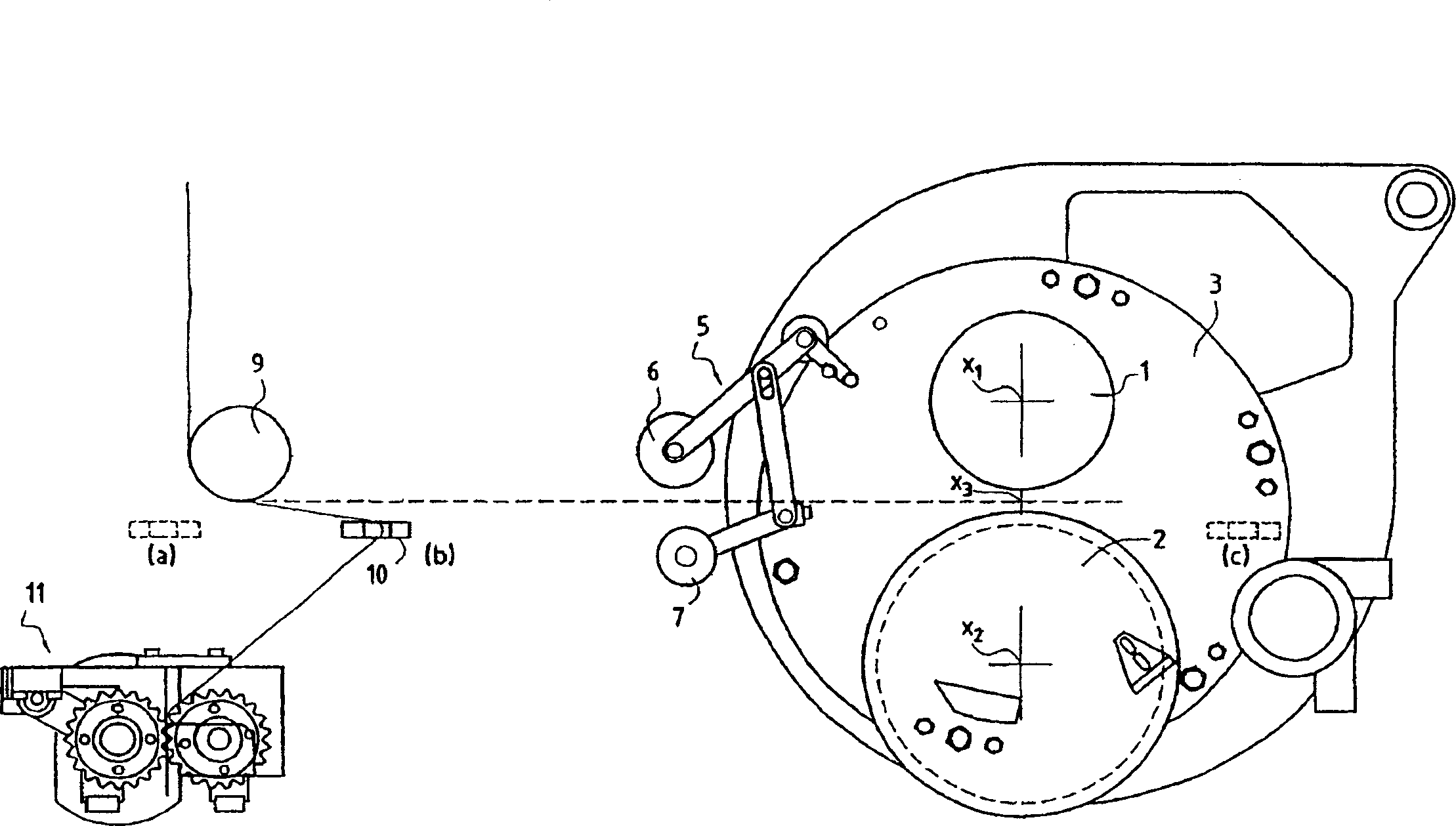

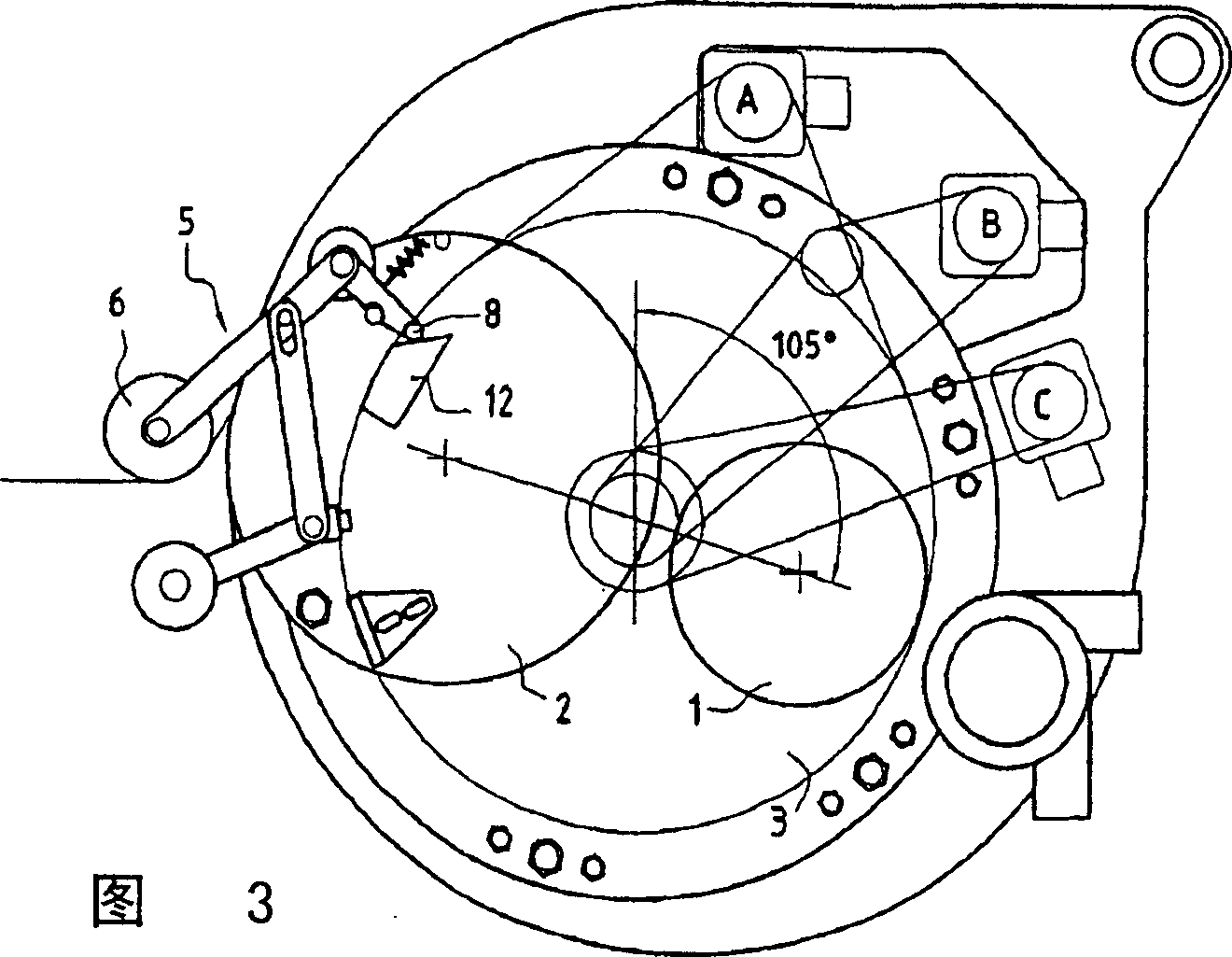

[0054] figure 1 The main elements of the invention are shown in .

[0055] As is known, this cutting machine comprises a knife wheel 1 equipped with knives protruding along its radius. The cutting tool is not shown in the figure. The cutting machine also comprises an anvil wheel 2, the axis x2 of which is parallel to the axis x1 of the knife holder wheel 1; when the two wheels approach each other, they come into contact by their generatrices and rotate in opposite directions to each other, thus producing cutting area.

[0056] The respective tangential speeds of the wheels 1, 2 must of course be equal and the clamping between the wheels 1, 2 can be adjusted according to the different parameters of the cutting such as the diameter of the fibers that make up the string, the properties of the string, the cutting speed ... moment.

[0057] In addition, a processing wheel 4 can be arranged close to the anvil wheel 2 in order to dress the outer surface of the anvil wheel 2 when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com