5-amino-salicylic acid intercalation medicinal slow-release agent and production thereof

A technology of aminosalicylic acid and sustained-release agent, applied in the field of 5-aminosalicylic acid sustained-release dosage form and its assembly, to achieve the effect of suppressing peculiar smell, good taste and good sustained-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Add Zn(NO 3 ) 2 ·6H 2 O (1.788g, 0.006mol) and Al(NO 3 ) 3 9H 2 O (0.56g, 0.0015mol) is equal to 4 and is made into mixed solution A with 100ml water according to Zn / Al molar ratio, in addition NaOH (0.5g, 0.0125mol) and 5-amino salicylic acid former drug (0.60g, 0.004mol ) Mix solution B with 50ml of water at a molar ratio equal to 3:1.

[0035] 2. Put the mixed solution A in the container, under N 2 Under protection, the mixed solution B was slowly dropped into the vigorously stirred mixed solution A, and after the addition was completed, the pH was adjusted to 8.5 with 0.1M NaOH.

[0036] 3. The resulting slurry was crystallized at 60°C for 48 hours, filtered, washed, and dried in an oven at 60°C for 8 hours to obtain 5-aminosalicylic acid intercalated zinc-aluminum LDH. The water used in the process is decarbonized deionized water.

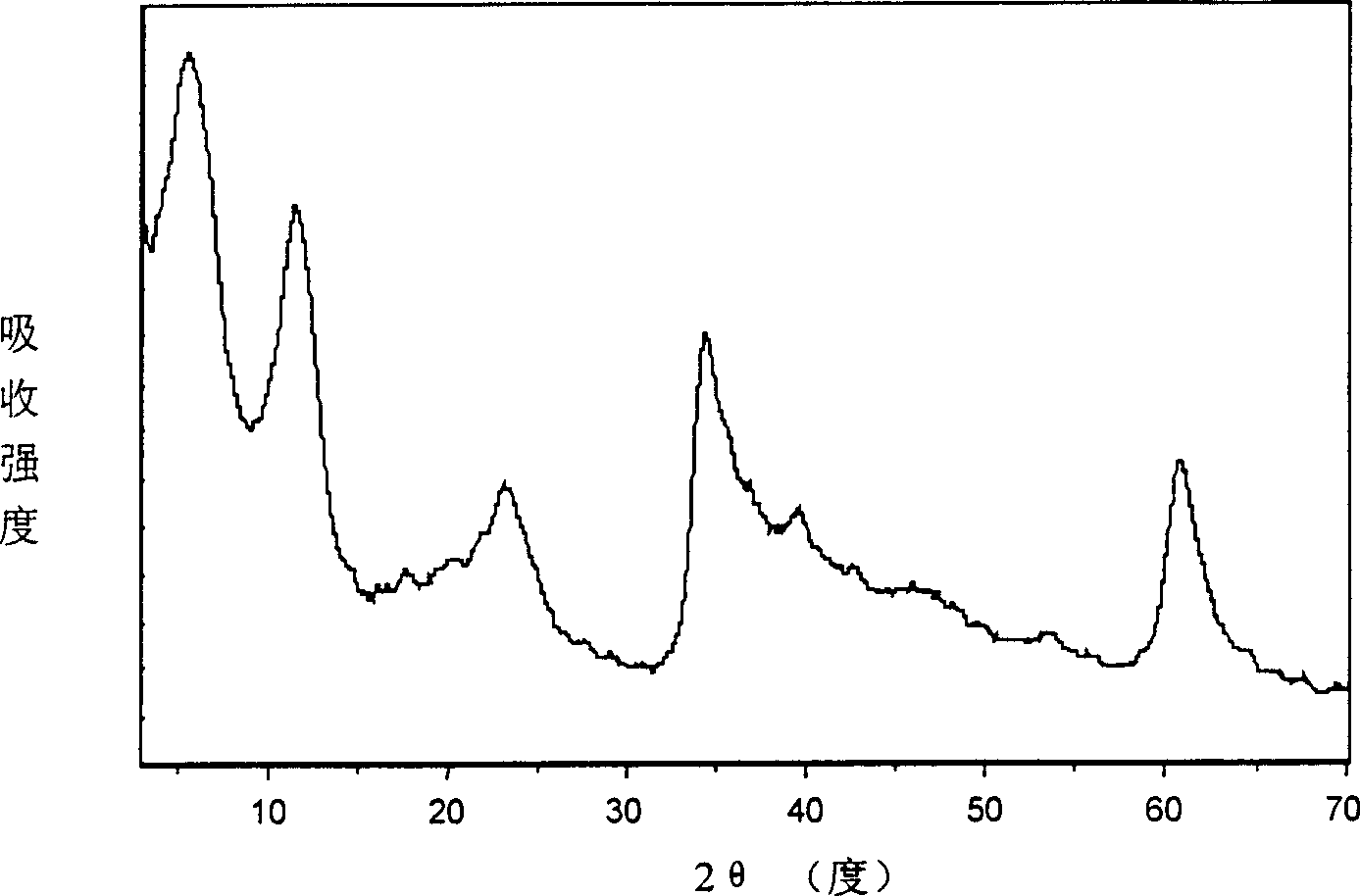

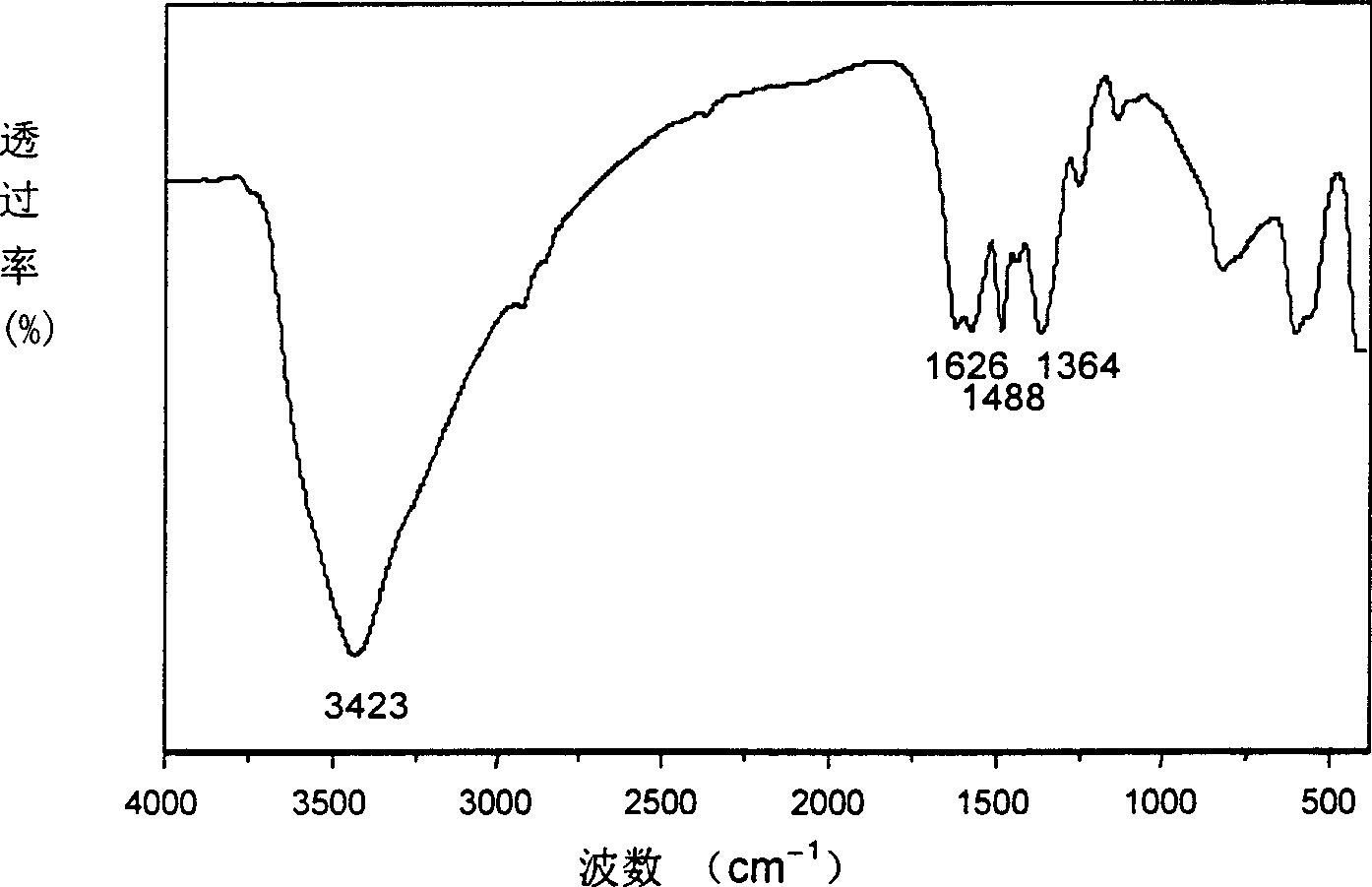

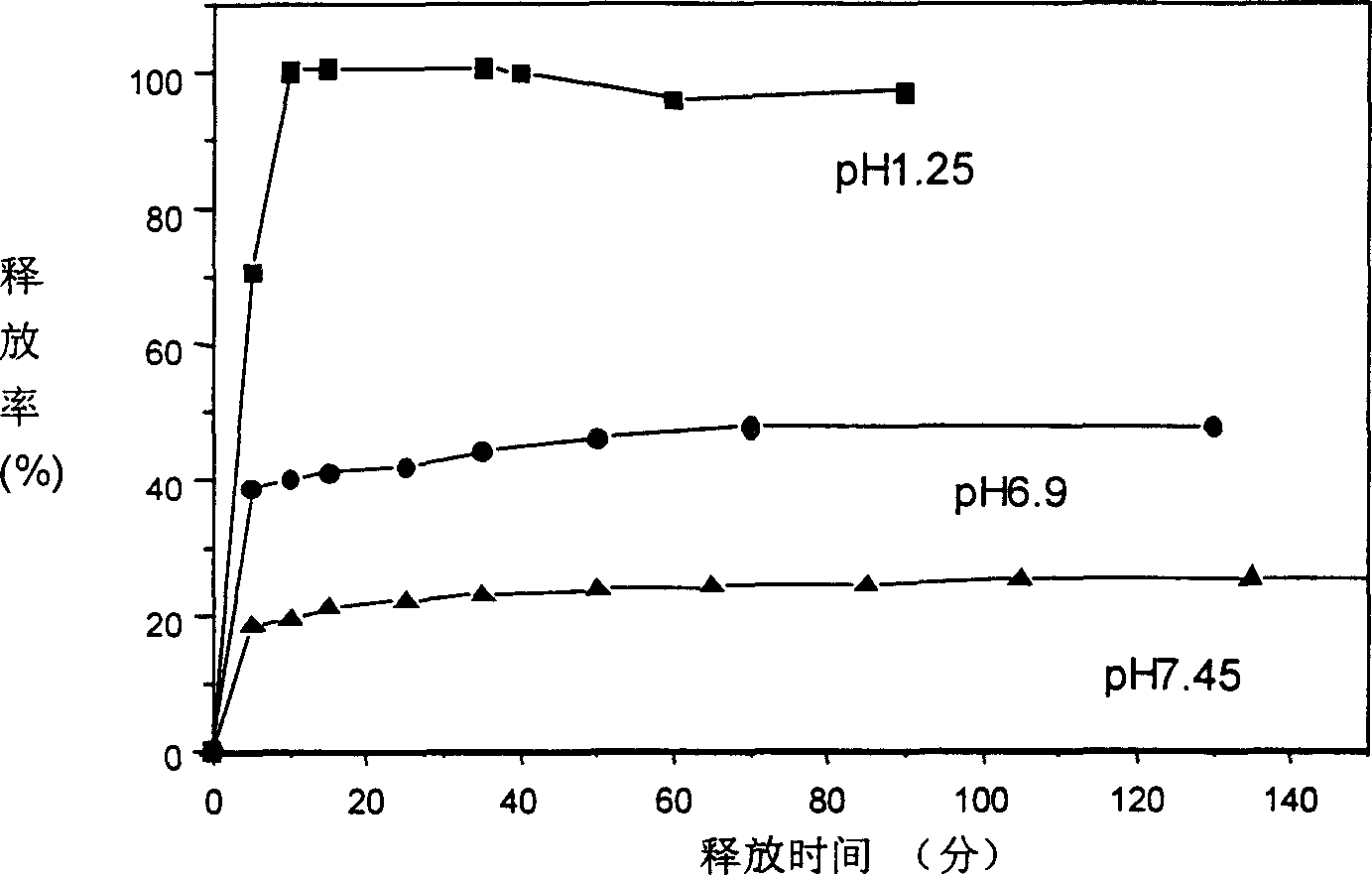

[0037] The obtained 5-ASA-LDHs is characterized by X-ray powder diffraction, and the results are shown in figure 1 ,Depen...

Embodiment 2

[0041] Step 1 is the same as embodiment 1;

[0042] Step 2: Drop mixed solution A and mixed solution B into a container filled with deionized water at the same time, stir vigorously, and control the pH to 8.5;

[0043] Step 3: crystallize the obtained slurry at 60°C for 48h, filter with suction, wash, and dry in an oven at 60°C for 8h to obtain 5-aminosalicylic acid intercalated zinc-aluminum LDH. The water used in the process is decarbonized deionized water.

[0044] Adopt the method for embodiment 1 to analyze product, obtain its chemical formula / formation as: [Zn 0.79 Al 0.20 (OH) 2 ](C 7 h 6 NO 3 ) 0.20 0.86H 2 O, 5-aminosalicylic acid content of 17.98%, water content of 12.27%;

Embodiment 3

[0046] Mg(NO 3 ) 2 ·6H 2 O (1.14g, 0.0045mol) and Al(NO 3 ) 3 9H 2 O (0.56g, 0.0015mol) is equal to 3 and is made into mixed solution A with 50ml water according to Mg / Al molar ratio, in addition NaOH (0.4g, 0.01mol) / 5-amino salicylic acid former drug (0.60g, 0.004mol )) Mix solution B, N with 150ml of water at a molar ratio equal to 2.5:1 2 Slowly drip the mixed alkali solution into the salt solution under protection, stir vigorously, and adjust the pH to 10 with 0.1M NaOH after the addition is complete. The slurry was crystallized at 60°C for 18 hours, suction filtered, washed, and dried at 60°C for 8 hours to obtain 5-aminosalicylic acid intercalated magnesium aluminum LDH. The water used in the process is decarbonized deionized water.

[0047] Adopt the method for embodiment 1 to analyze product, obtain its chemical formula / form as: Mg 0.74 Al 0.26 (OH) 2 (C 7 h 6 NO 3 -1 ) 0.18 (CO 3 2- ) 0.04 0.7H 2 O, 5-aminosalicylic acid content of 26.6%, water cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com