Needle with transfer spring

A technology of loop transfer and loop formation, which is applied in knitting, weft knitting, textile and papermaking, etc., to ensure smooth running, reduce safety distance, and reduce lateral deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

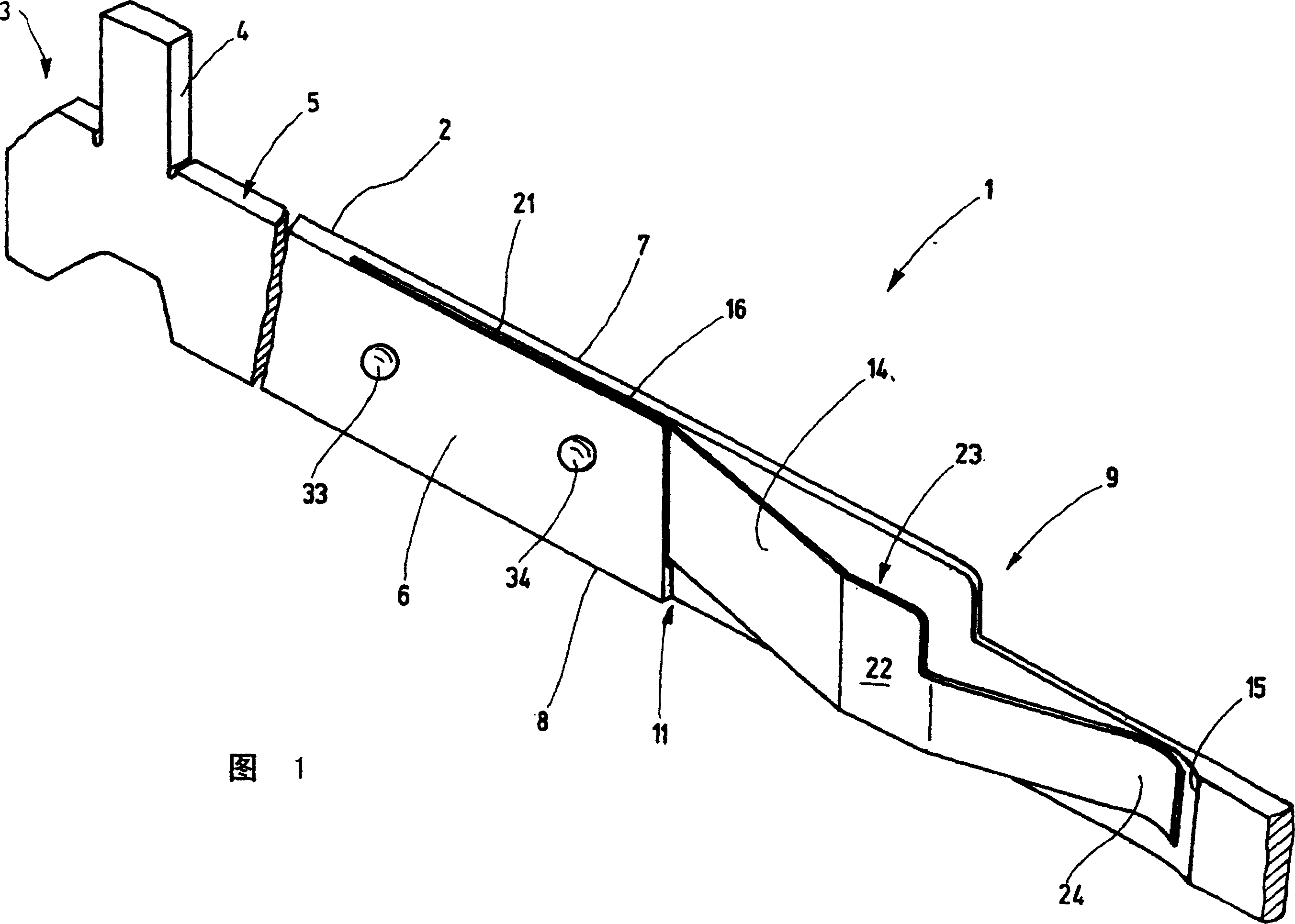

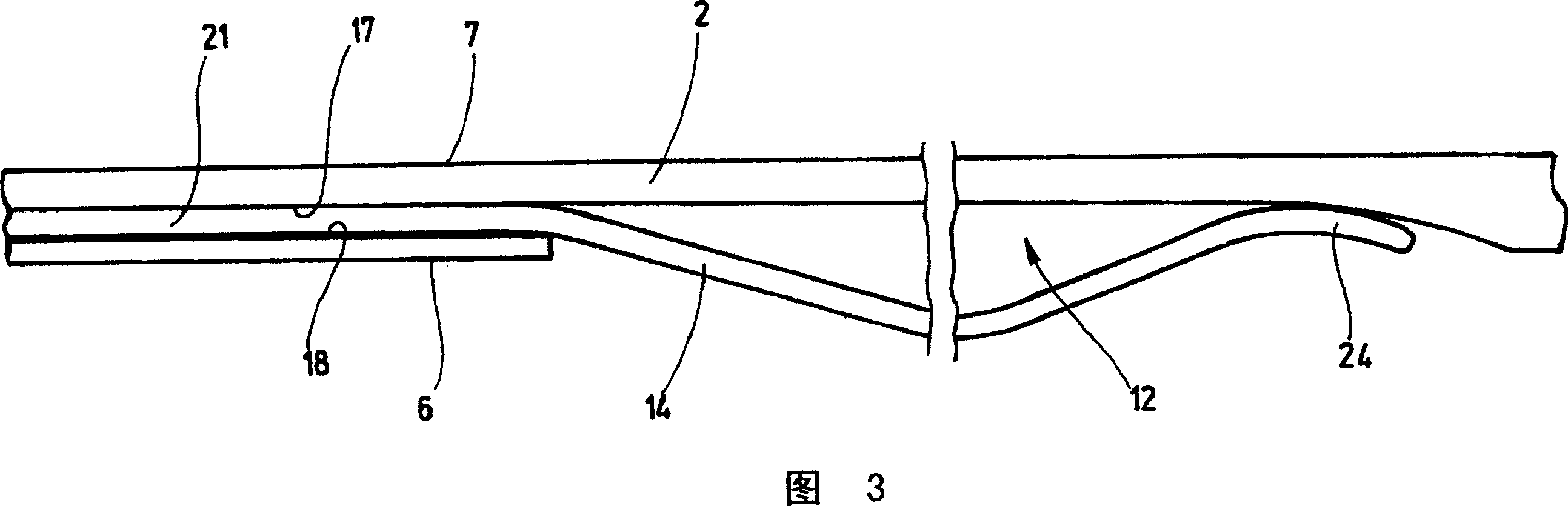

[0026] FIG. 1 shows a detail of a needle 1 for a knitting machine in the form of a transfer needle. The needle has a needle body 2 which supports a hook, not otherwise shown, at an end cut off in FIG. 1 . Arranged at its other end 3 or at another suitable location is a needle foot 4 which protrudes from the narrow side 5 of the needle body 2 , which is substantially rectangular in cross section. The narrow side 5 forms the upper side of the needle. On both sides of the narrow side 5 , the needle body 2 has two flat sides 6 , 7 which form substantially flat, closed surfaces aligned parallel to one another. On the underside of the needle body 2 there is a further narrow side 8 parallel to the narrow side 5 which forms the back of the needle.

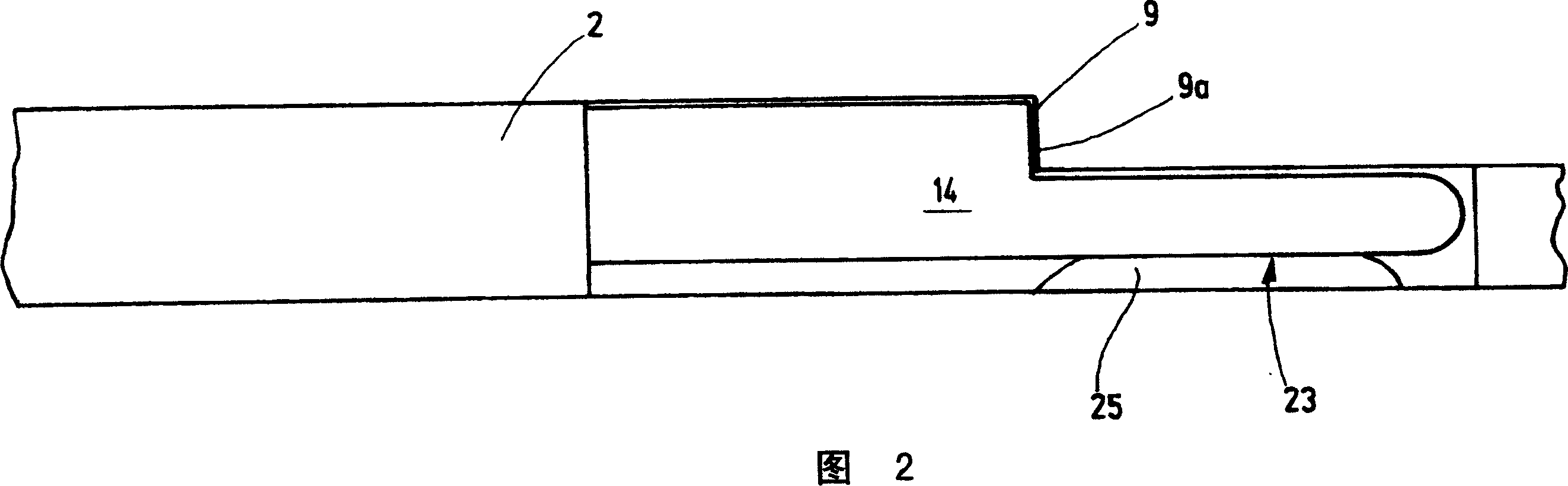

[0027] The measured height of the needle body 2 between the narrow sides 5 , 8 can vary along the length of the needle body 2 . For example, as shown in FIG. 1, a step 9 can be provided where the height decreases towards a not shown hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com