A circular weft knitting machine

A weft knitting machine and circular technology, which is applied in the field of knitting circular weft knitting machines, can solve the problems of reducing the yarn transmission rate, reducing the speed of the yarn feeder, and reducing production efficiency, so as to increase tension, reduce workload, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

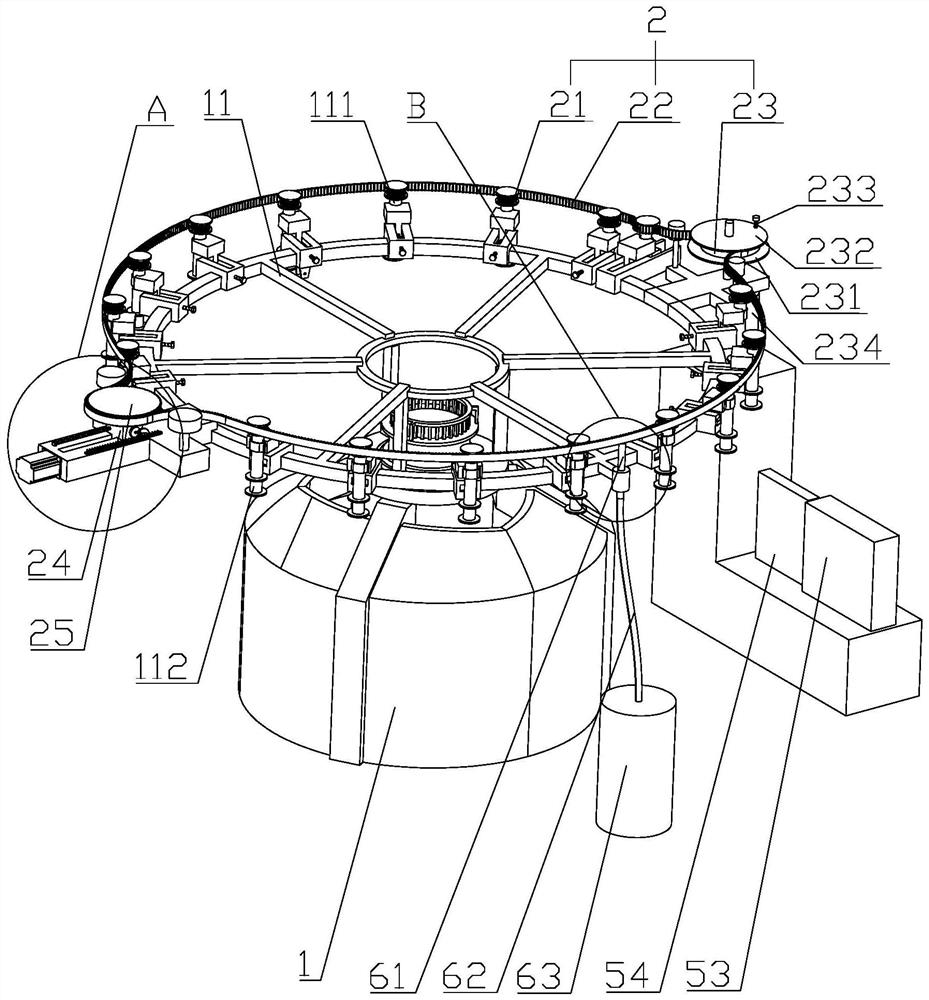

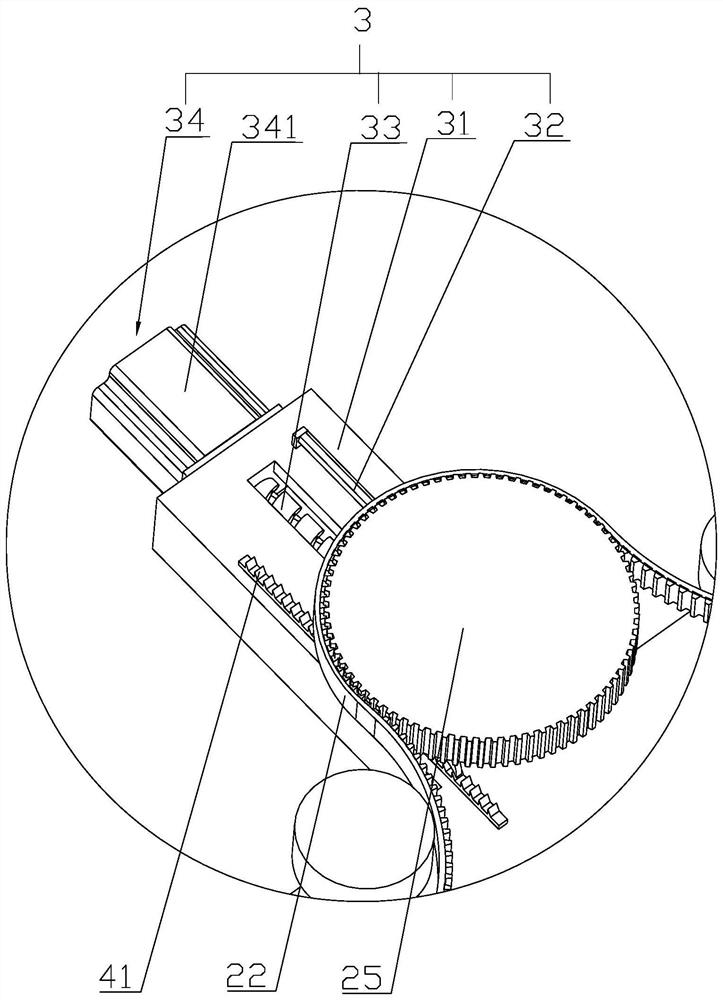

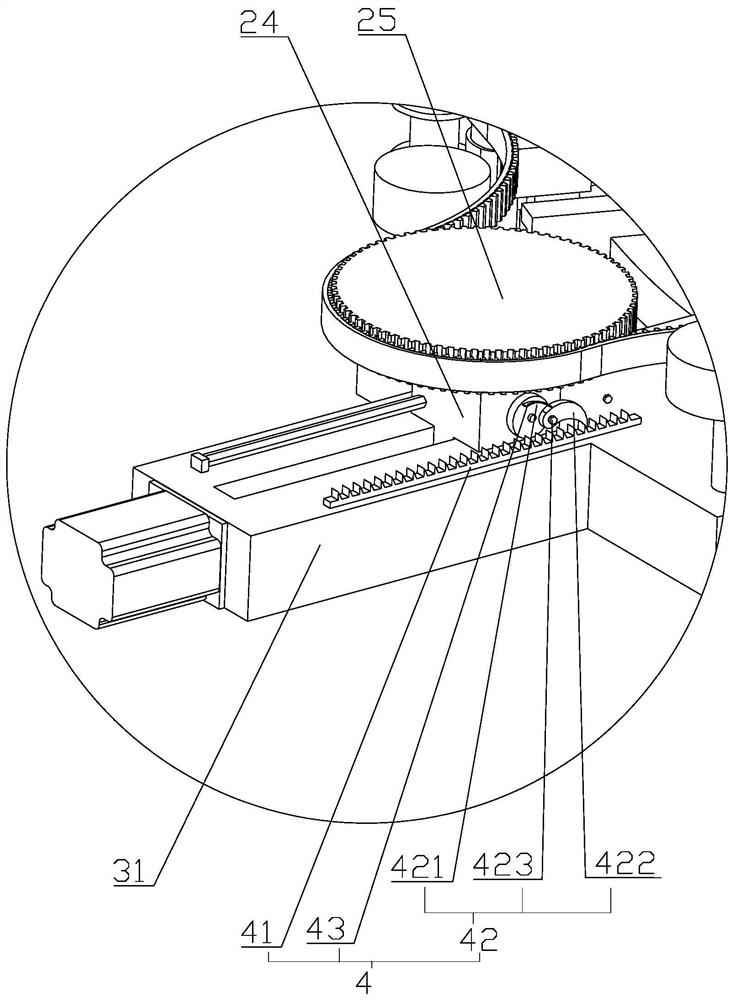

[0038] refer to figure 1 , is a kind of knitting circular weft knitting machine disclosed by the present invention, comprising a creel 11, a plurality of yarn feeders 111 distributed around the circumference of the creel 11, a yarn feeder 112 arranged on the yarn feeder 111, and The driving mechanism 2 arranged on the frame 1 drives the yarn delivery wheel 112 to run. The creel 11 is in the shape of a circular frame, and the frame 1 supporting the creel 11 is placed on the ground, and the creel 11 is fixed on the top of the frame 1 by screws. The yarn bobbin of thread, the yarn on the yarn bobbin enters in the weft knitting machine after being transferred by the yarn feeder 111 for weaving.

[0039] The yarn feeders 111 are distributed at equal angular intervals along the circumference of the yarn frame 11, and the yarn feeder 112 is in the shape of a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com