Optical fiber cable for air-blown installation

A fiber optic cable and air blowing technology, applied in light guides, optics, optical components, etc., can solve problems such as poor flexibility and difficult laying of optical cables into curved or curved pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An optical cable for air blowing laying according to a preferred embodiment of the present invention will be described below with reference to the accompanying drawings. In the following description of the present invention, detailed descriptions of known functions and configurations included herein will be omitted for clarity.

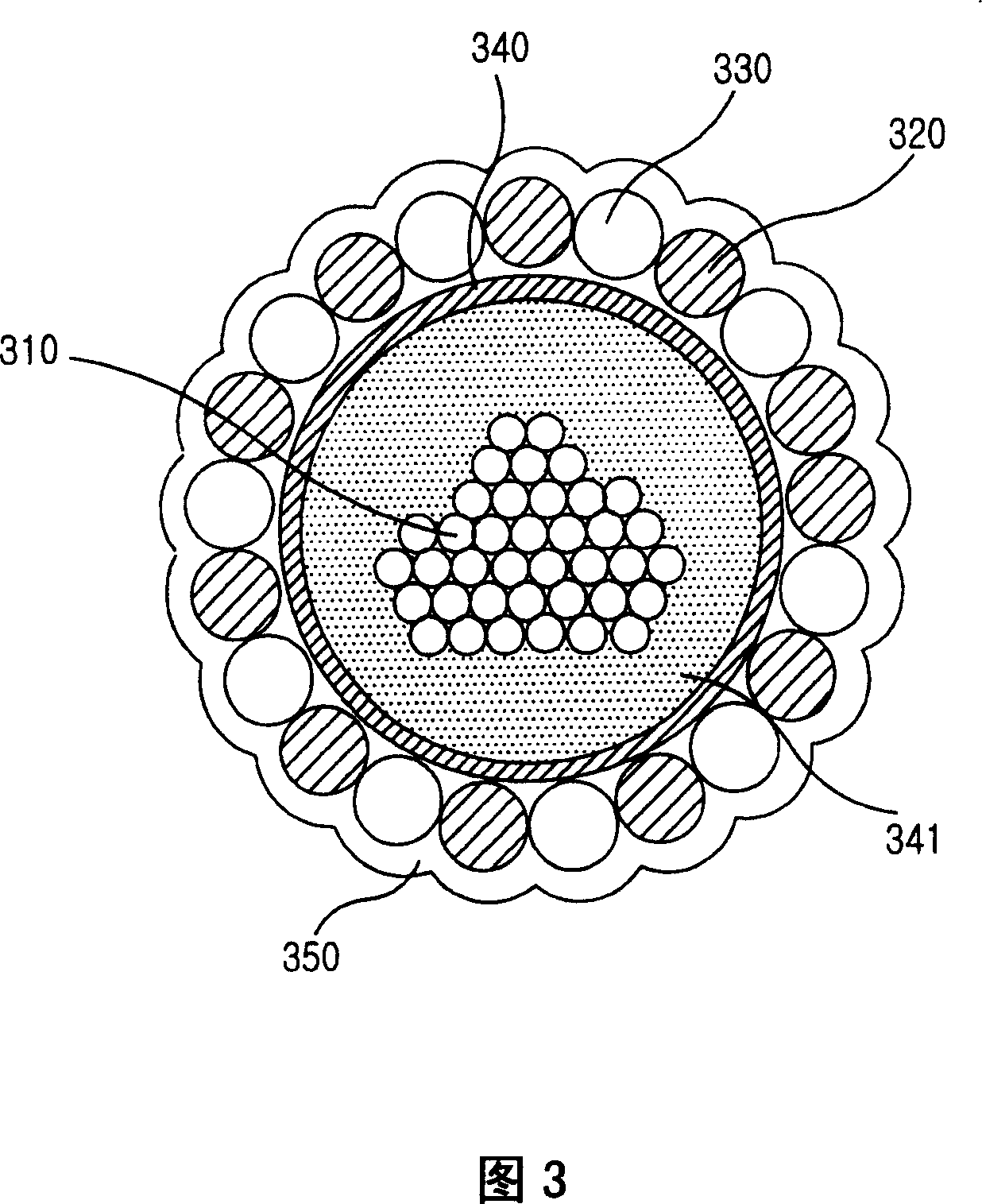

[0026] Fig. 3 shows the construction of a fiber optic cable with a single tube structure, which features a plurality of optical fibers, according to a preferred embodiment of the present invention. The optical cable includes a plurality of optical fibers 310 as a medium for transmitting optical signals; a tube 340 binding the optical fibers 310; a plurality of line fillers 330 surrounding the outer circumference of the tube 340; tension member 320; and outer sheath 350.

[0027] The optical fiber 310 serves as a medium for transmitting optical signals, and is installed inside the tube 340 . The empty space between the tube 340 and the optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com