Stack coil device and manufacturing method thereof

A coil device, non-magnetic technology, used in coil manufacturing, coil, inductor/transformer/magnet manufacturing, etc., can solve problems such as electromagnetic coupling and improvement of impedance characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

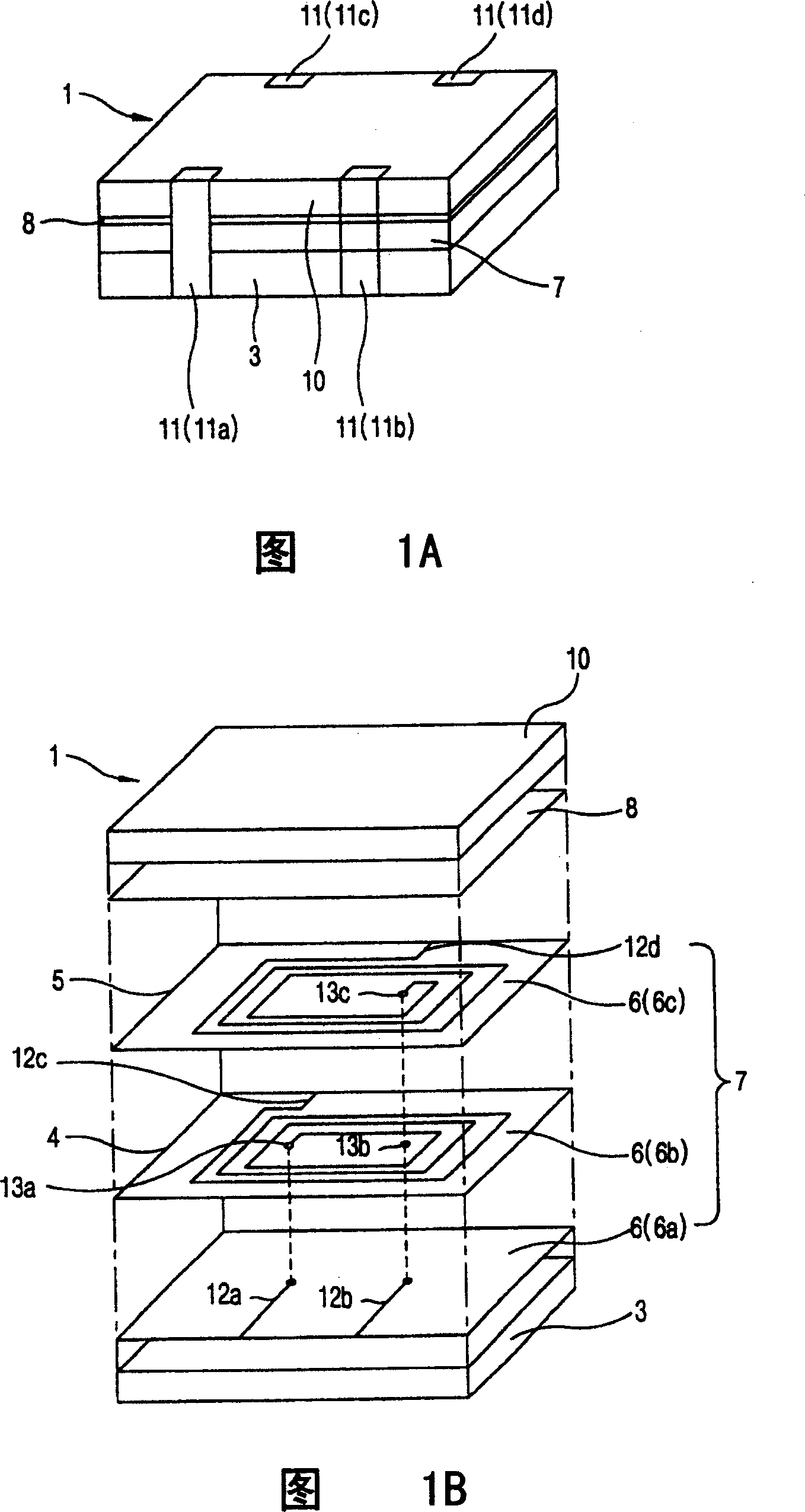

[0040] Reference will now be made in detail to preferred embodiments of the present invention, specific examples of which are shown in the accompanying drawings.

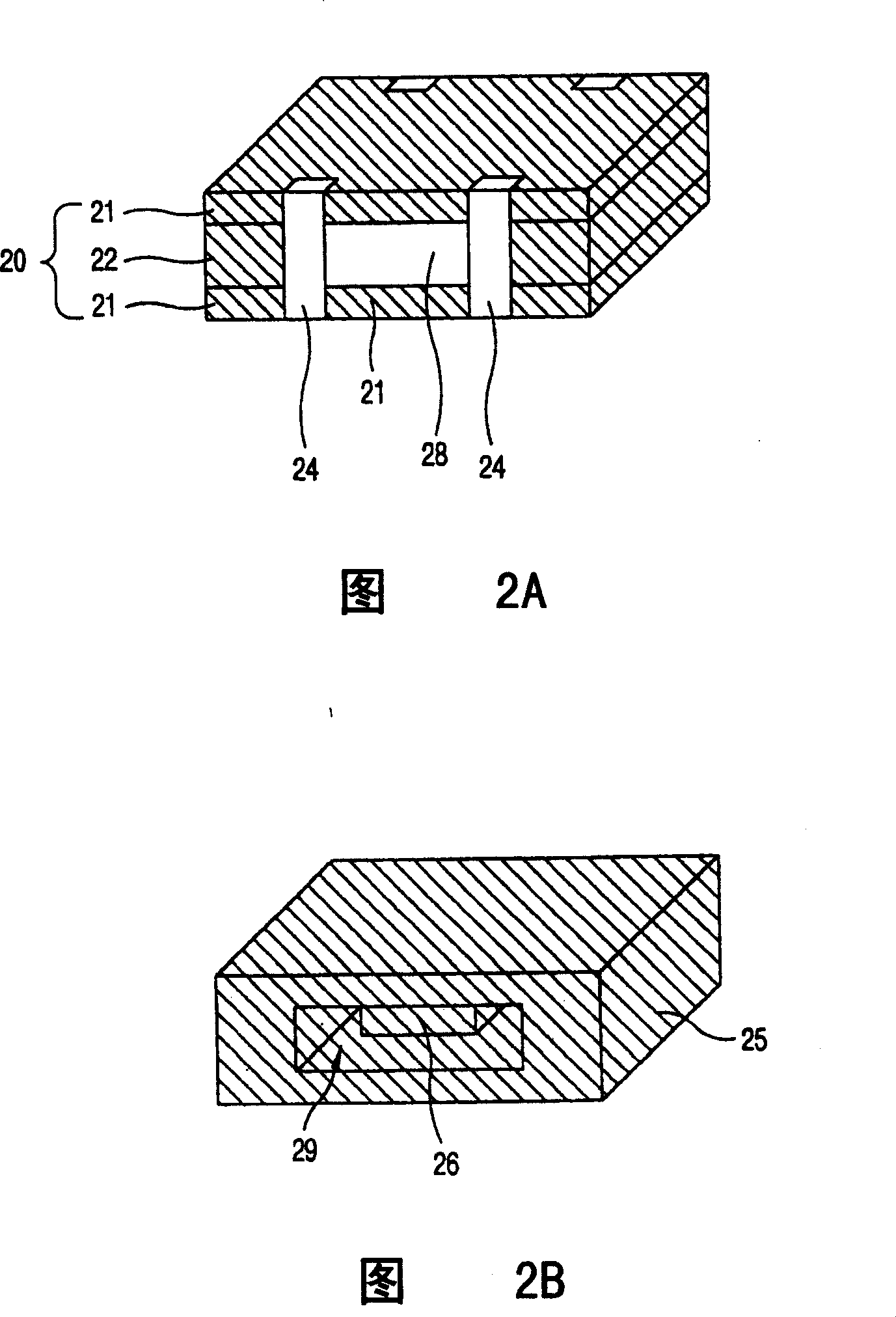

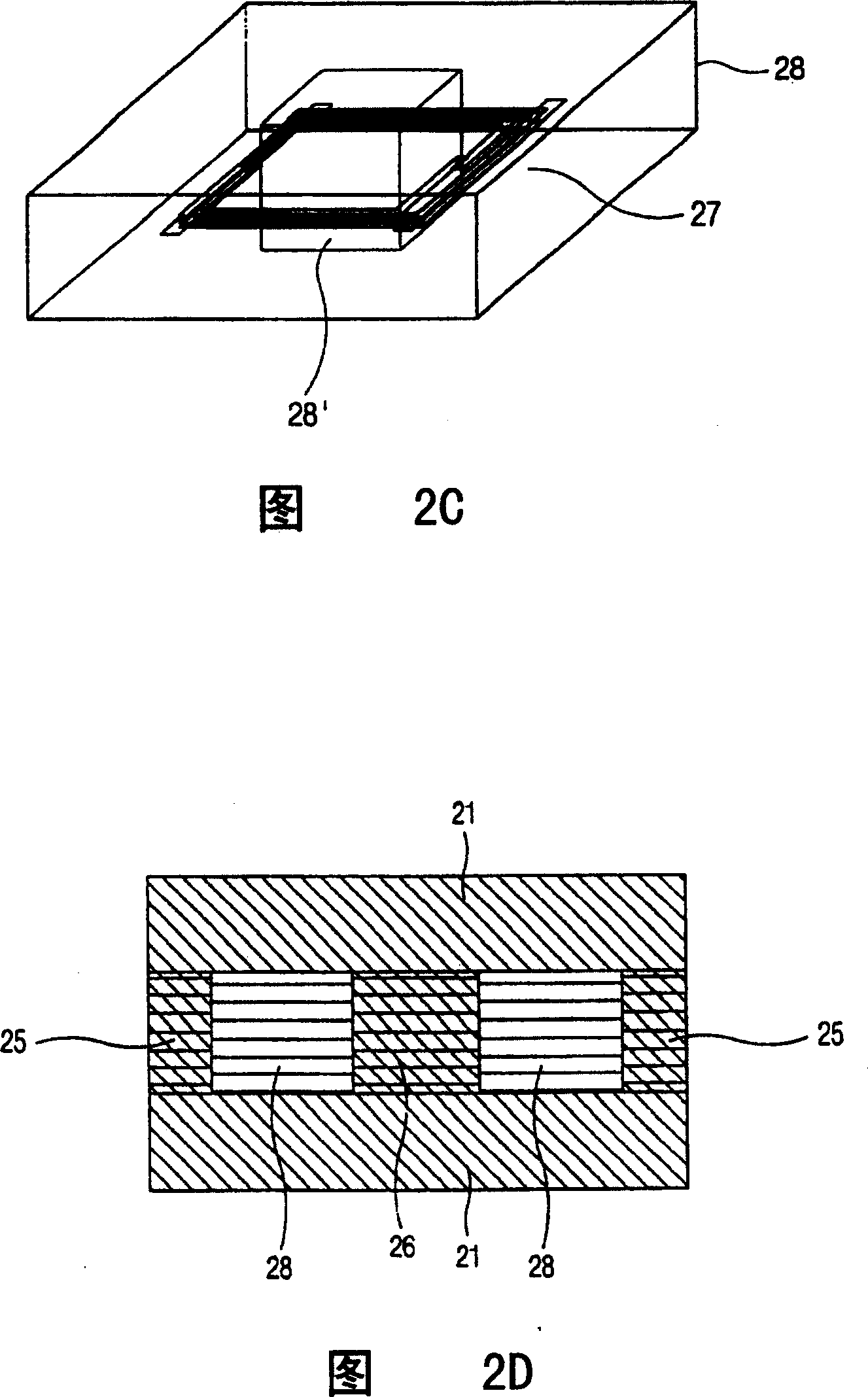

[0041] 2A-2D are perspective views illustrating the appearance and internal structure of the coil device of the present invention.

[0042] As shown in FIG. 2A , cover layers are formed on the upper and lower surfaces of the hexahedron-shaped coil device, and external electrode terminals 24 are formed on the outer peripheral surface of the stacked main body 20 . Also, a magnetic layer 22 and a nonmagnetic layer 28 are provided between the cover layers 21 .

[0043] Figure 2B shows only the magnetic inner layer in the coil arrangement, where the magnetic circuit can be shown. It can be seen here that in FIG. 2A , the central magnetic layer 26 is not shown because it is placed at the center of the non-magnetic electrode layer. The inner space 29 formed by the central magnetic layer 26 and the side magnetic layers 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com