Process and apparatus for flaxseed component separation

A technique of flaxseed and flaxseed hulls, applied in solid separation, chemical instruments and methods, separation of solids from solids by air flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

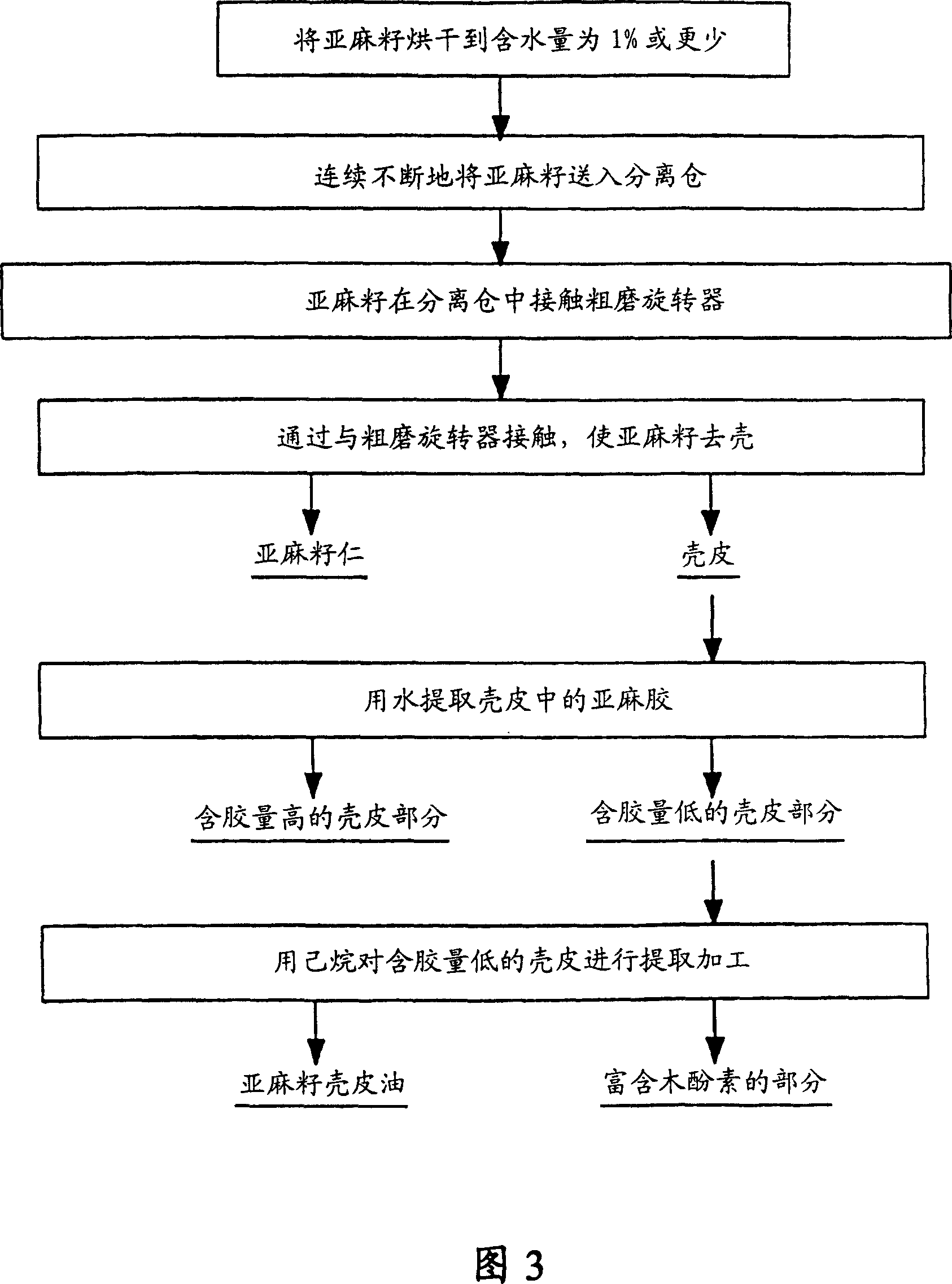

[0025] This process can effectively process the flaxseed on a laboratory scale or on a commercial scale, and separate various useful components extracted from the flaxseed.

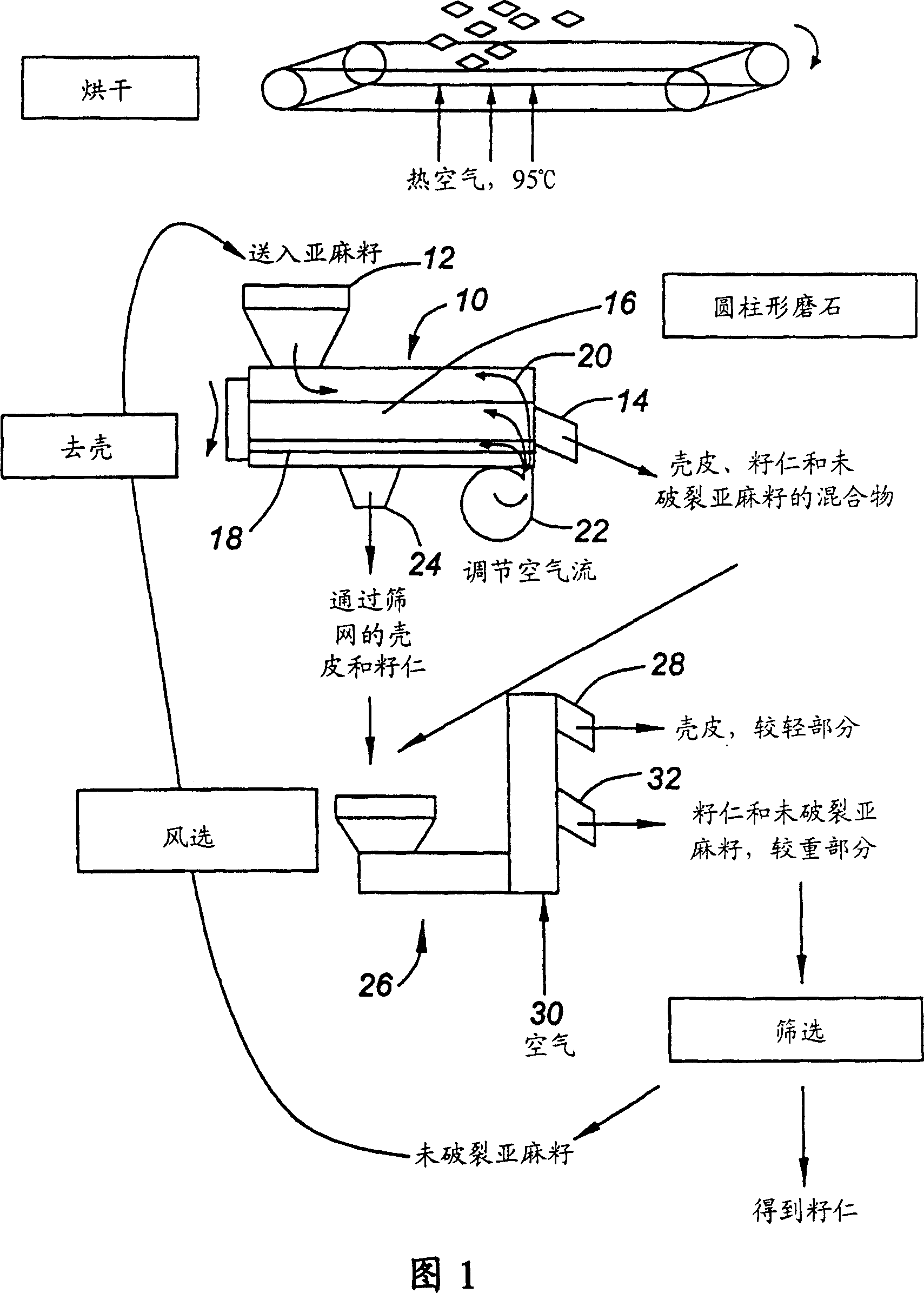

[0026]This article describes a continuous dehulling process that separates the husk and kernel of flaxseeds. Useful products can then be extracted from various flaxseed ingredients, including a product with a high lignan content. In addition, this process can also separate the various components of the linseed hull, so as to obtain the hull part rich in lignans.

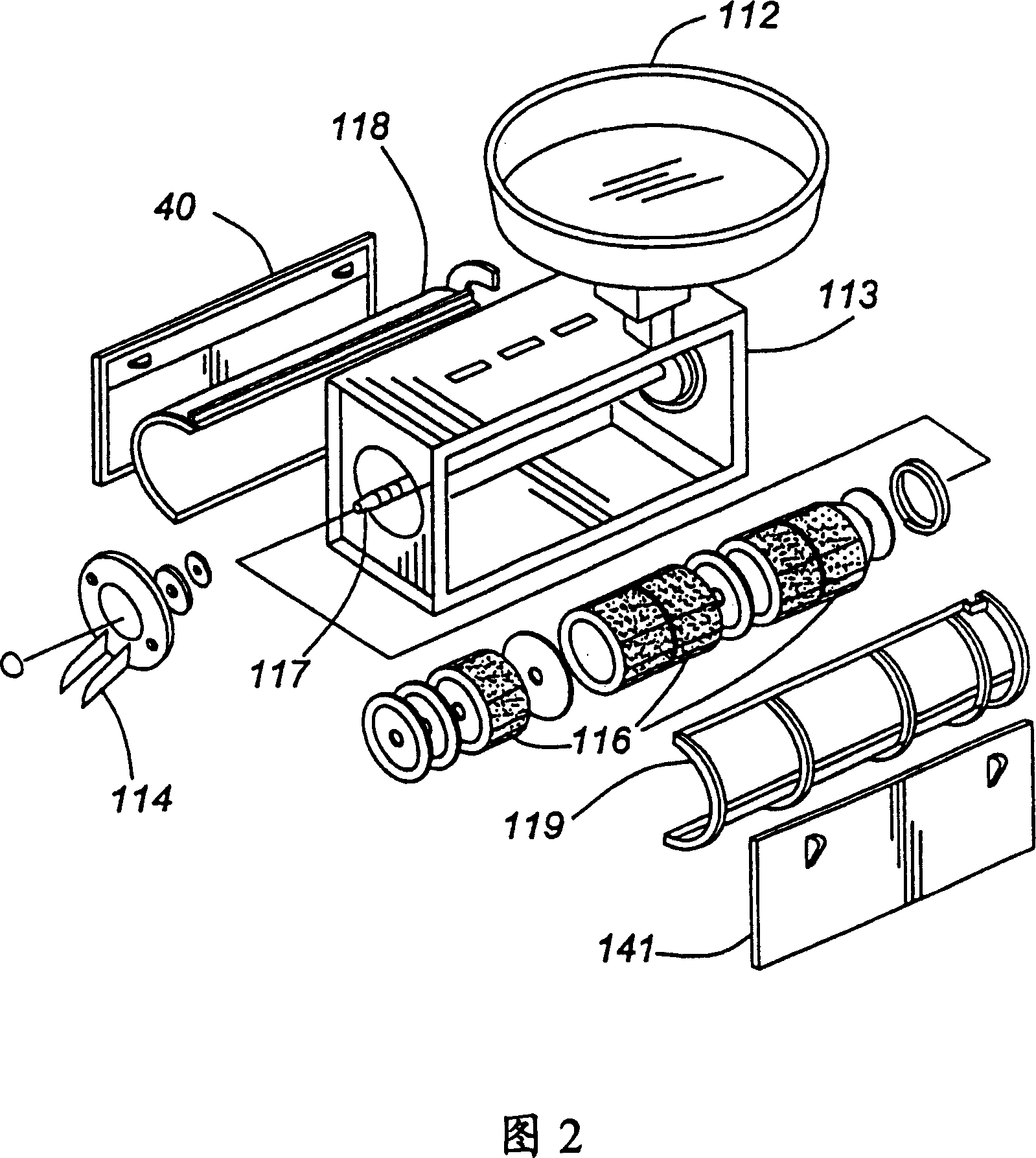

[0027] The invention provides a continuous processing method that can separate the linseed hulls and kernels. First, the linseed is dried to reduce the moisture content to about 0.5% to 3.0%; then, the dried linseed is continuously sent to a separation bin equipped with a coarse grinding spinner. In the separation chamber, the dried flaxseed passes through the coarse grinding rotator at an appropriate speed, so that the flaxseed can be dehulled by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com