Moving turbine blade

A blade, working technology, applied in the direction of blade support elements, engine elements, machines/engines, etc., can solve the problem of damage to turbine disks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

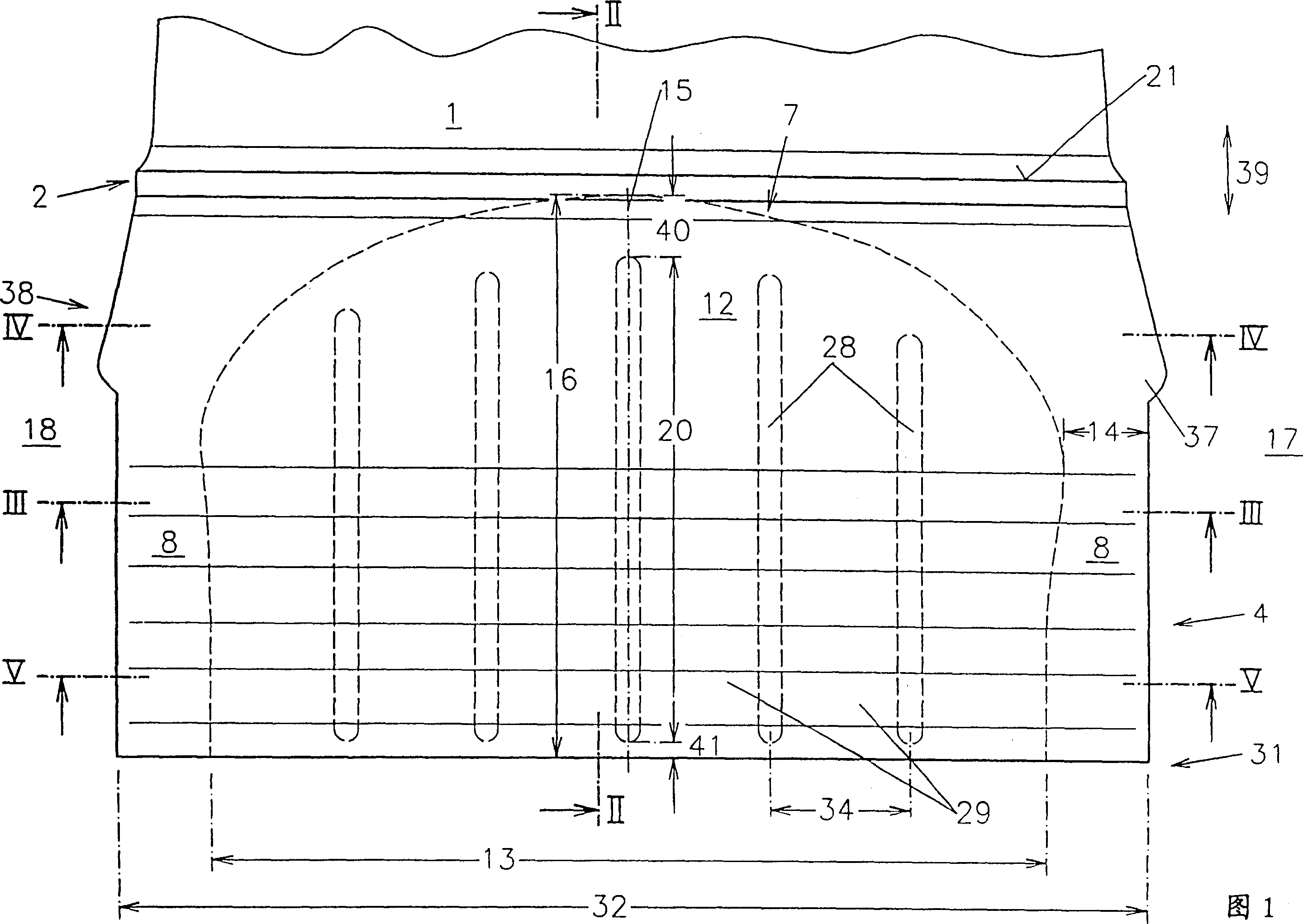

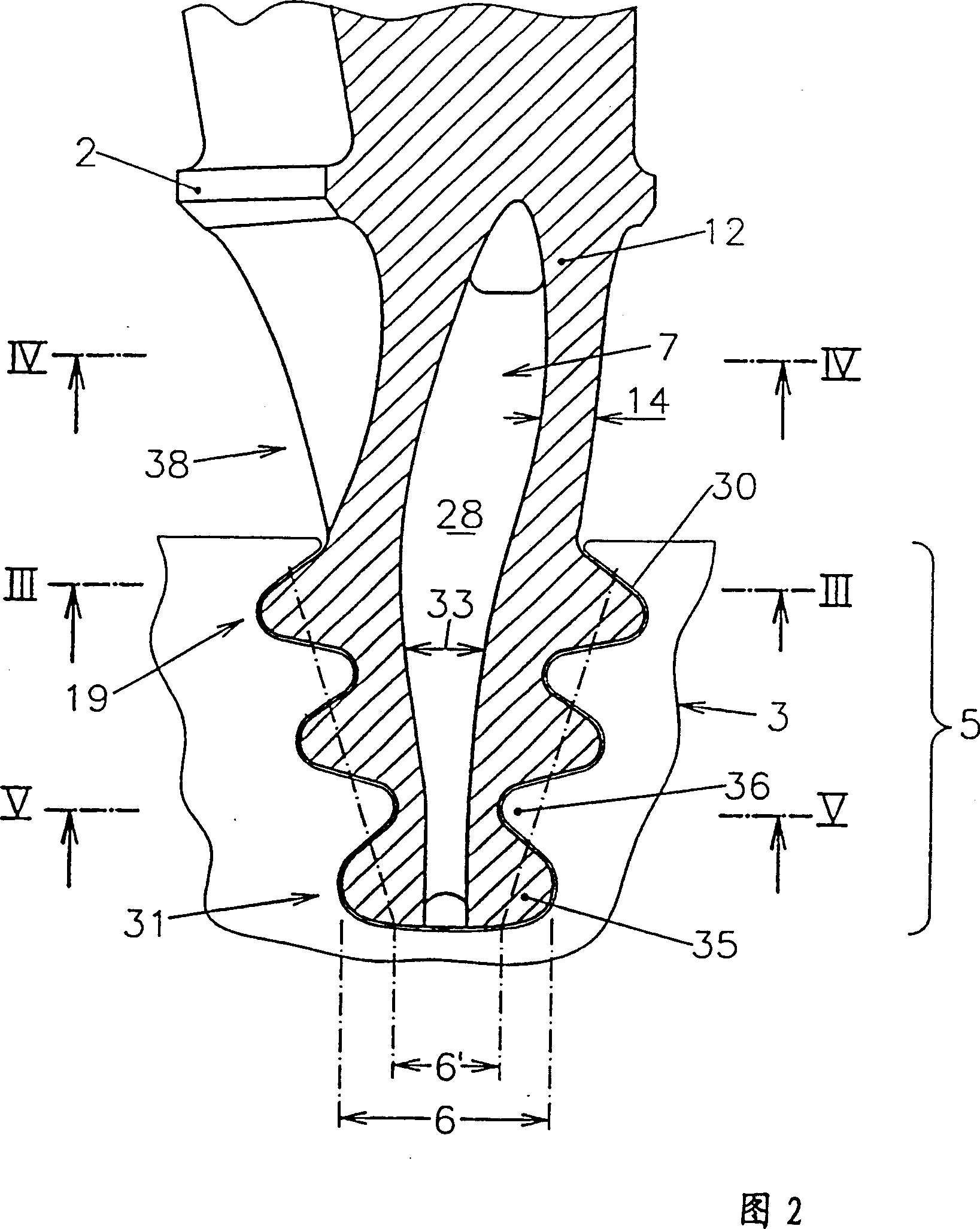

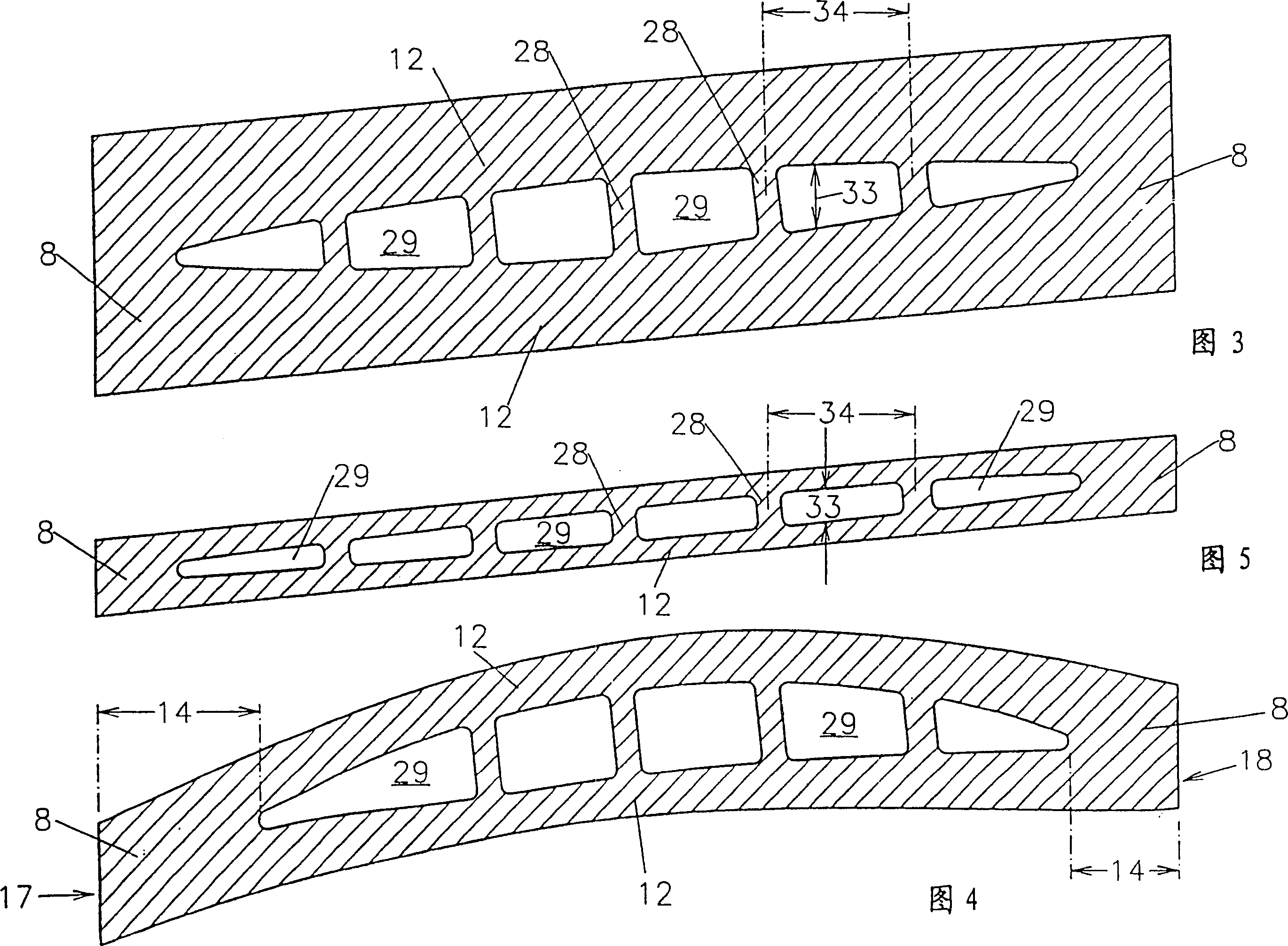

[0024] FIG. 1 shows a turbine blade root 4 as well as a platform 2 and a partial airfoil 1 in radial section. The blade root 4 is inserted into a mortise 30 of the turbine wheel disk 3 and fixed in a form-closed manner by means of the mortise teeth 35 of the blade root 4 and the corresponding teeth 36 on the mortise 30 , as shown in FIG. 2 . The blade root 4, the platform 2 and the airfoil 1 are integrally formed, preferably poured into one body. The side-by-side airfoils 1 provide resistance to the flowing hot gas and change its speed and direction, thereby causing the turbine wheel disk 3 to rotate at a high rotational speed around the disk axis. The centrifugal forces that occur in this case essentially have to be absorbed by the teeth 35 of the blade root 4 and the teeth 36 of the groove 30 . Especially in the case of turbine blades without internal cooling, a large part of the turbine blade is usually solid and thus has a high weight, which places a considerable load on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com