Coupling structure of optical fiber and light wave guide

A coupling structure and optical waveguide technology, applied in the field of optical coupling structure, can solve the problems of light loss, increase of light propagation loss, and influence of beam luminous flux, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a further understanding of the purpose of the present invention, structural features and functions thereof, the accompanying drawings are described in detail as follows:

[0023] The present invention takes the passive optical splitter made by the optical waveguide as an embodiment, and manufactures the optical path and coupling structure constructed by the passive optical splitter and the optical fiber on the substrate, and can be applied to the optical fiber communication system and other optical systems.

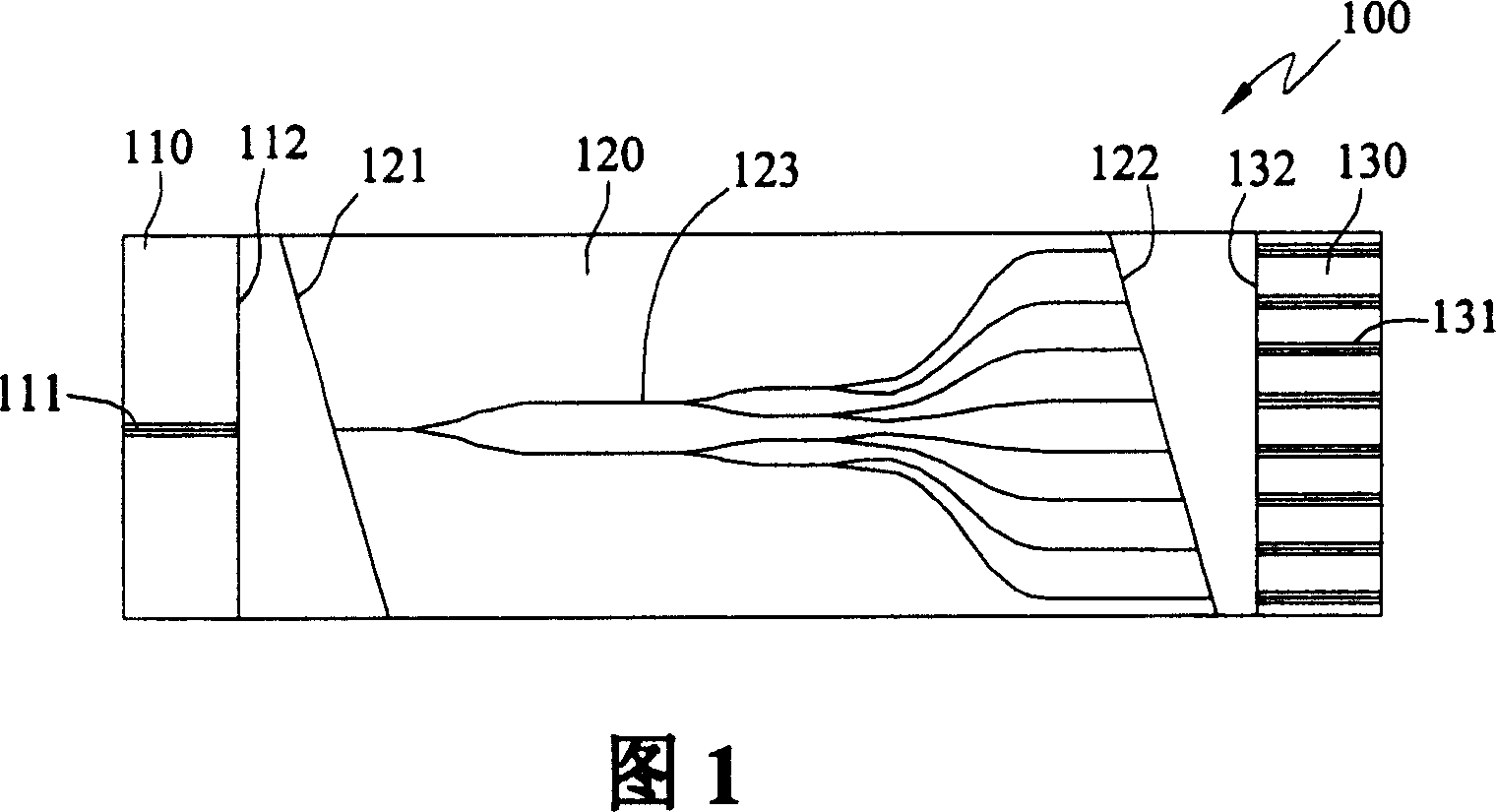

[0024] Please refer to FIG. 1 , which is a schematic diagram of a first embodiment of the present invention. The light input region 110 , the light waveguide region 120 and the light output region 130 are formed on the silicon substrate 100 . The light input area 110 has a first auxiliary alignment groove 111 to accommodate an input optical fiber (not shown) to transmit the input light to the optical waveguide area 120, the light input area 110 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com