Bottom hole hammer reverse circulation follow pipe drill

A down-the-hole hammer and reverse circulation technology, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of drill sticking, affecting the service life of the drill bit, and the diameter of the running casing is limited, so as to achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

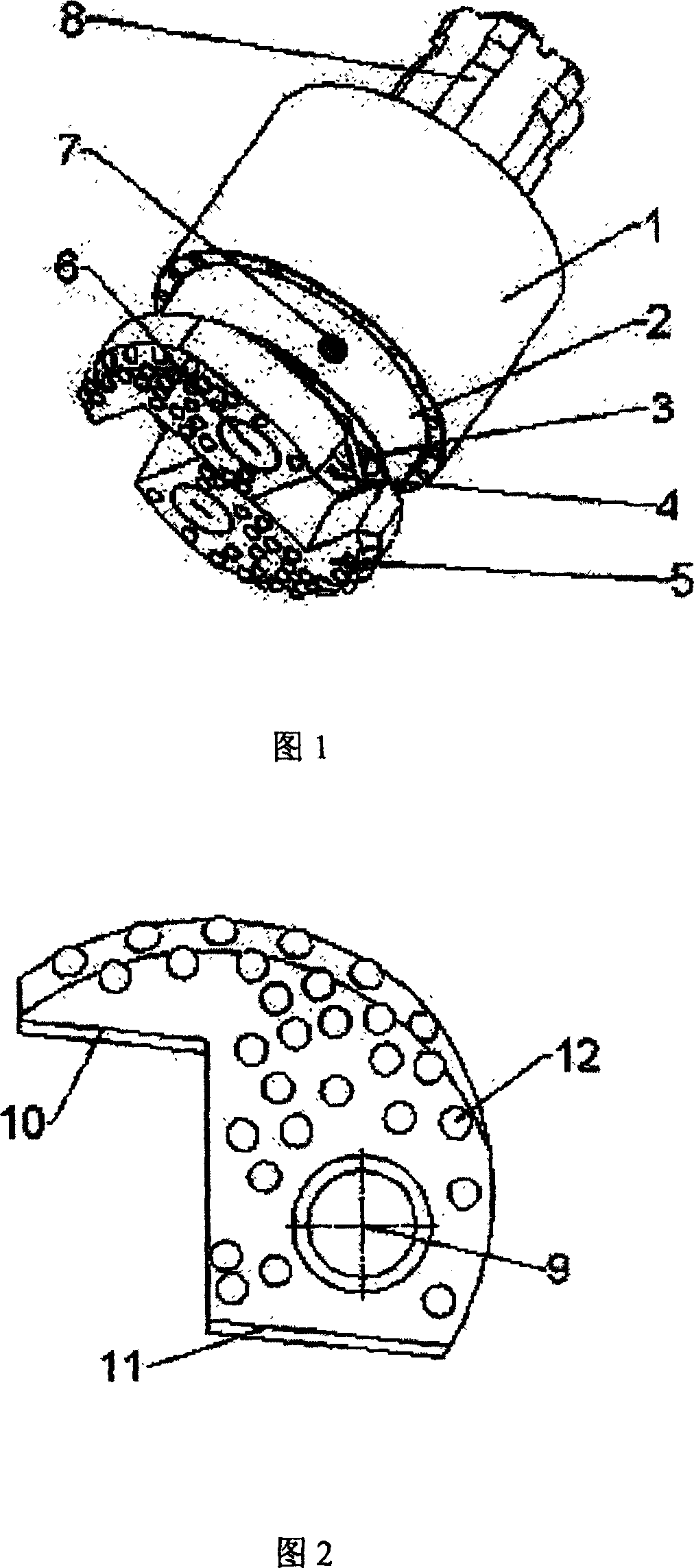

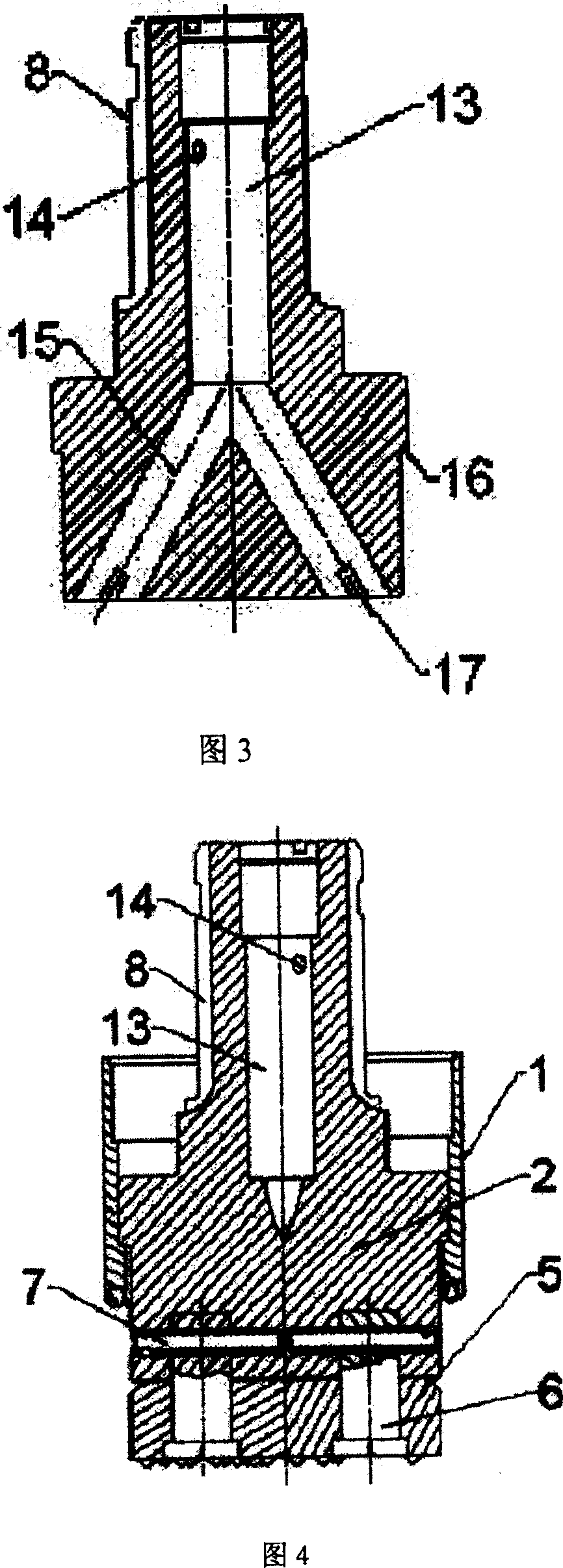

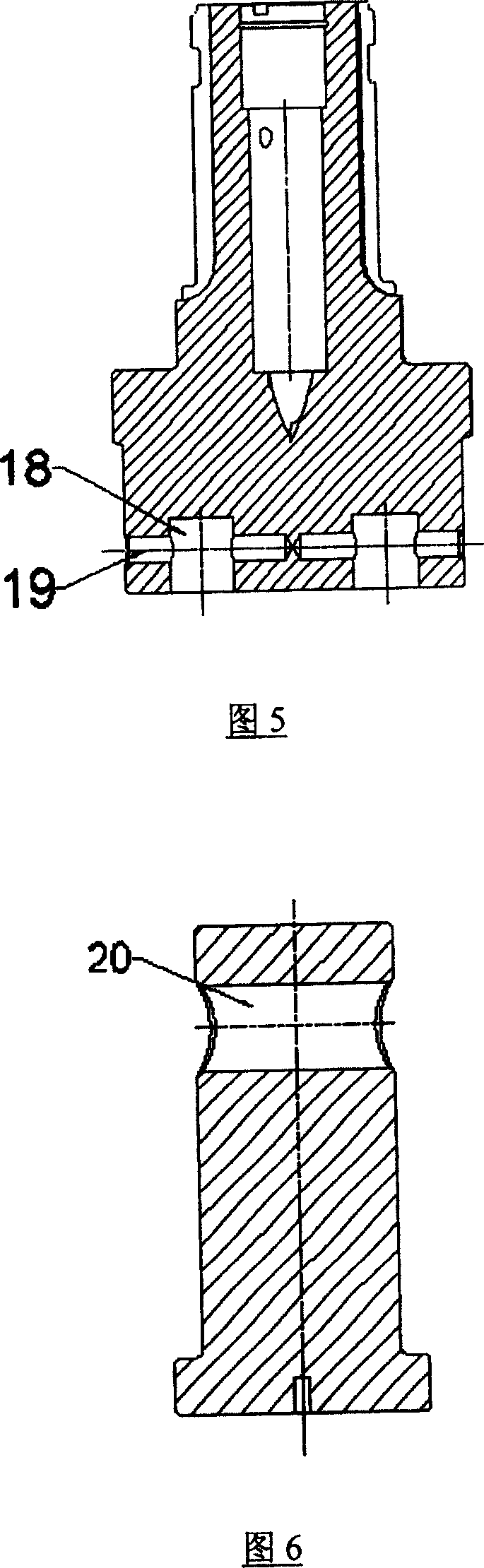

[0015] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0016] The bottom surface of the drill body 2 is provided with two bottom surface pin holes 18 parallel to the axis of the drill body 2, and the lower part of the drill body 2 is provided with two lower pin holes 19 perpendicular to the axis of the drill body 2, and the two bearing pins 6 pass through the two drill bits respectively. The respective pin holes 9 of the petals 5 and the pin holes 19 at the lower part of the drill body 2 suspend two drill valve valves 5 respectively, and the elastic pin 7 passes through the pin holes at the top of the two pin shafts 6 through the pin holes 19 at the lower part of the drill body 2. 20. Fix the pin shaft 6 on the drill body 2. The pin shaft 6 is not only the pin for hanging the two drill valve valves 5, but also the respective rotation axes of the two drill valve valves 5. The joint surface of the two drill valve valves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com