Apparatus for blanking and processing profile notches of rubber sealing strip

A technology of rubber seals and processing devices, which is applied in metal processing and other directions, can solve problems such as no solution for pressing force, difficulty in feeding materials, and affecting processing efficiency, etc., to meet the requirements of mass production, simple structure, and improved The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

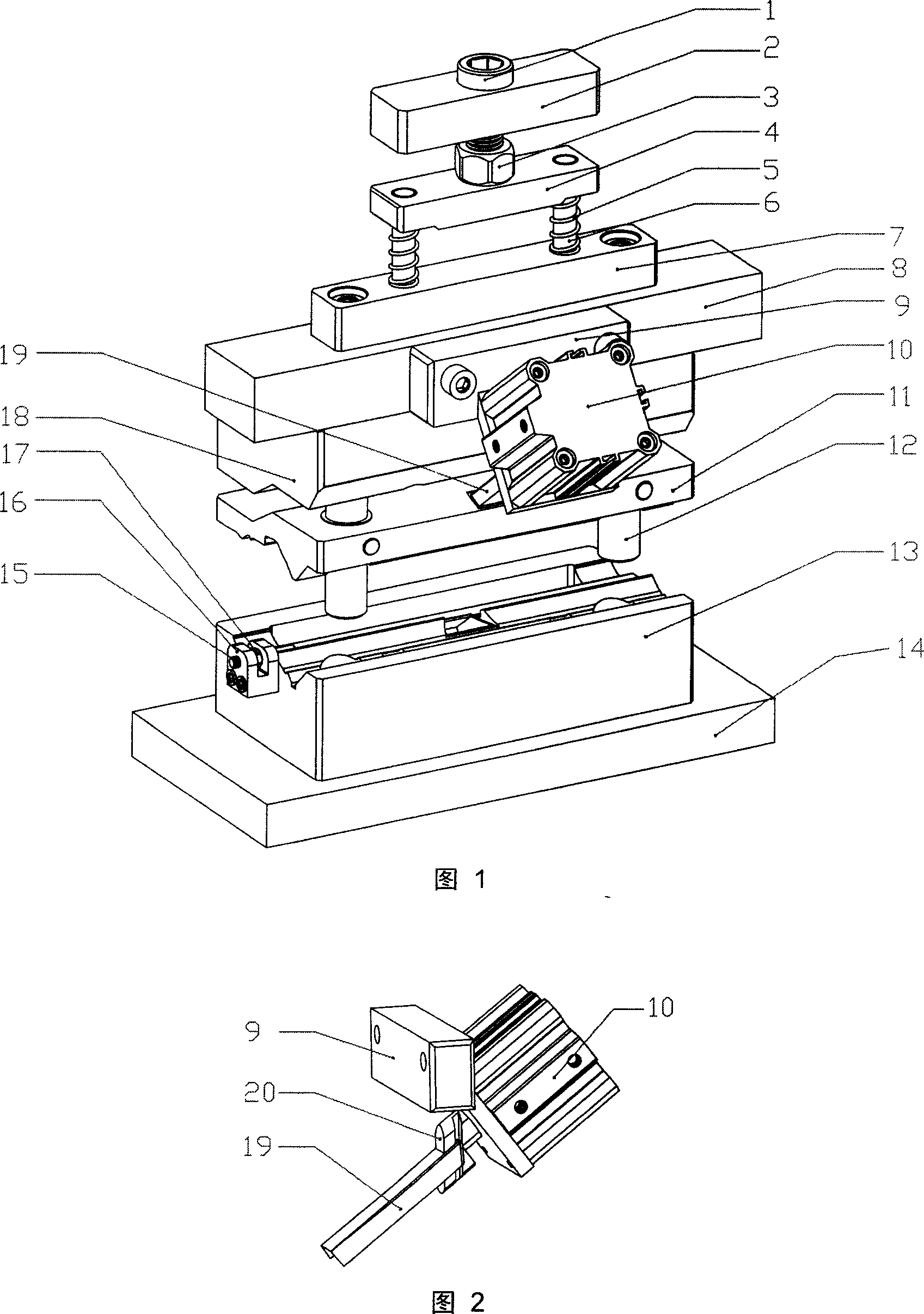

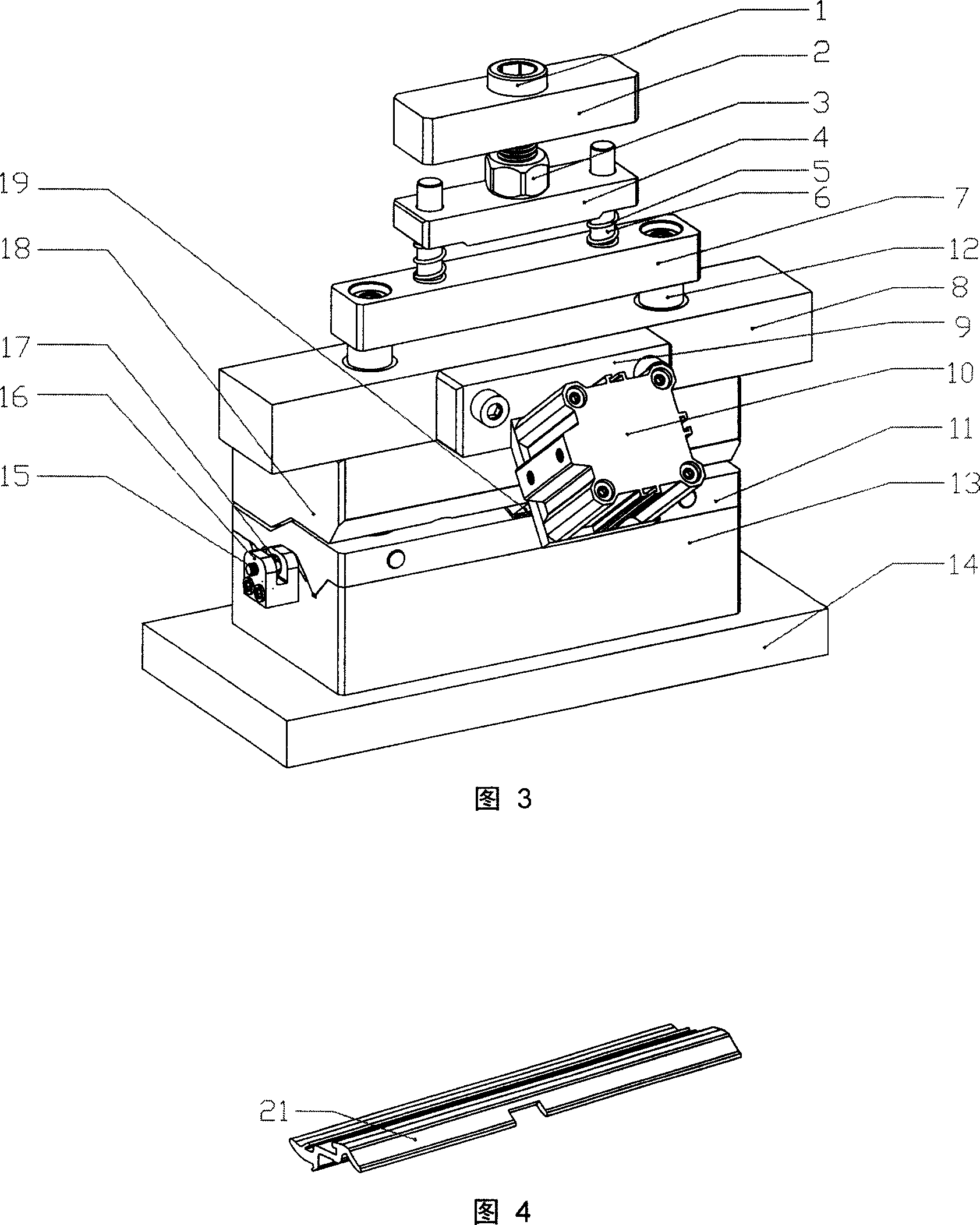

[0029] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] A typical implementation of the present invention is shown in the accompanying drawings, which is used to realize the die-cutting of the profile cutout of a sealing strip as shown in FIG. 4 , where the plane where the cutout is located is at a certain angle to the horizontal plane.

[0031] Fig. 1 is a three-dimensional structure diagram of the device for punching and punching the rubber sealing strip profile of the present invention. As shown in Figure 1, the device consists of a lower die part, an upper die part and an oblique punching part. The lower mold part is mainly composed of a lower module 13 and a lateral positioning mechanism; the upper mold part is mainly composed of a pressing plate 11, a tool clamping module 18, a guide post 12 and a pressing mechanism.

[0032] The lower module 13 is installed on the working platform 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com