Catalytic system for hydro-conversion of naphtha

一种加氢转化、催化剂的技术,应用在催化系统领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

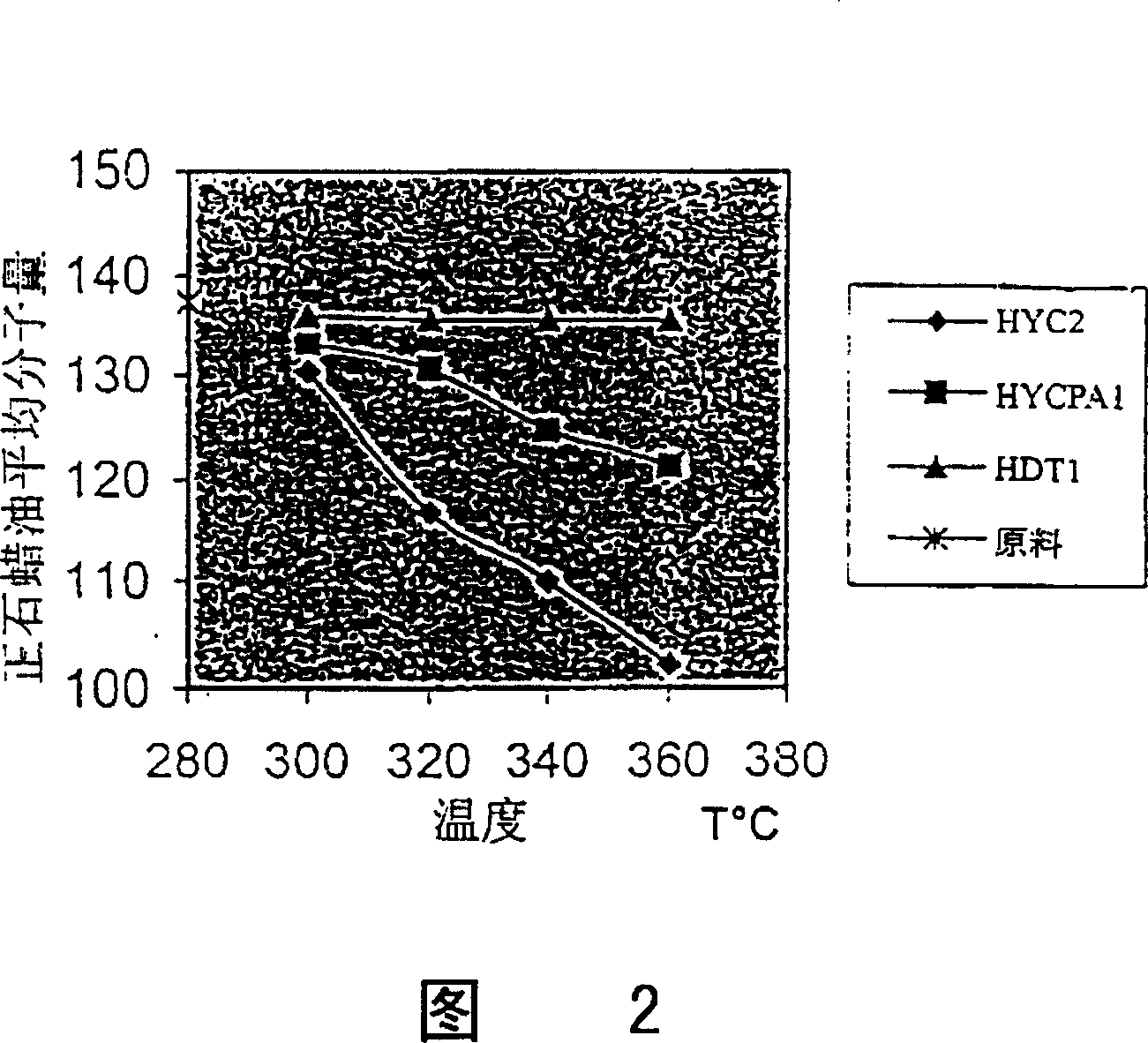

[0070] A commercially available hydrotreating catalyst (HDT1) with nickel, molybdenum and phosphorus (18% by weight) attached to its support alumina, 10 cubic centimeters of this catalyst was activated at 280 ° C, and Amuay refinery was carried out according to the above methodology The plant's FCC C9+ naphtha is evaluated. The results are shown in Table 2.

[0071] The resulting olefin hydrogenation activity was high (between 93.0% and 94.28% by weight). As expected, the hydrodesulfurization activity increased from 92.1% to 97% (by weight) with the increase of temperature. Similarly, when the temperature increased from 300°C to 600°C, the hydrodenitrogenation activity also increased from 93.5% to more than 97% ( weight). However, the average molecular weight of the n-paraffin oil was very close to that of the n-paraffin oil in the feedstock, indicating a low acid catalysis.

[0072] General Catalyst HDT1

Embodiment 2

[0074] Make commercially available alumina powder B (Condea TM ) with a silicon-aluminum ratio of 11.7 proton state MFI zeolite powder (ST-5) (see Table 3 for its chemical composition) and both are powders, according to the ratio of 50% (weight) zeolite and 50% (weight) alumina mix.

[0075] MFI

Zeolite

General chemical formula

nAl

(10 20 / g)

Crystal size

(μm)

surface area

(m 2 / g)

ST-5

Na 0.23 h 7.38 Si 88.4 o 192

7.5

0.8

332

[0076] *nAl(10 20 / g): by chemical general formula and Avogadro constant (6.02×10 23 ) to calculate the total number of Bronsted bits

[0077] During the mixing of the two solids, 2.5% by weight acetic acid was added proportionally, or 2.4 grams of solid per milliliter of acid, was added to the mixture. After mixing, the solids were mixed with a twin extrusion mixer until uniformly mixed. After mixing well, squeeze the slurry into 1 / 16-inch extruded s...

Embodiment 3

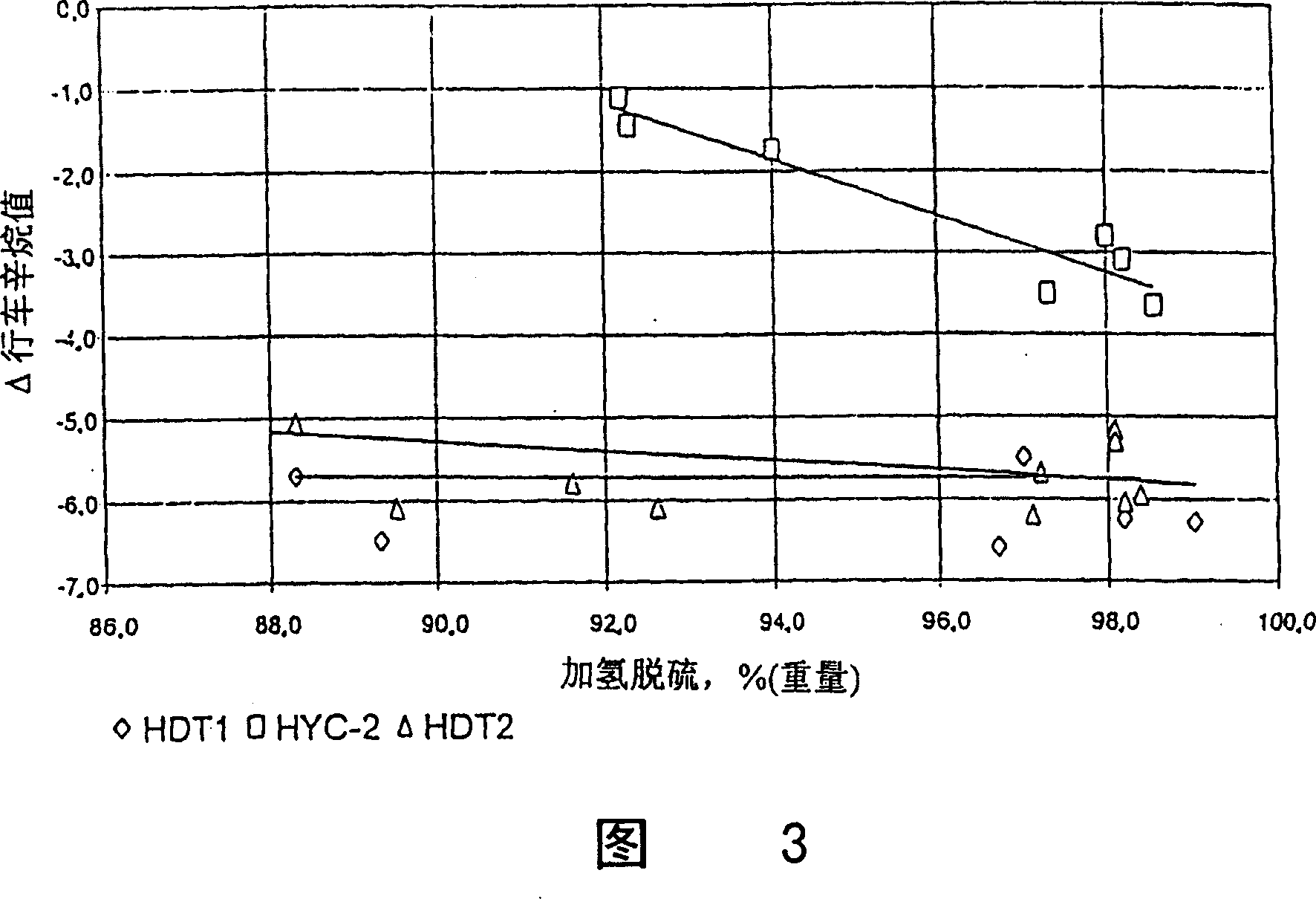

[0082] Table 4 shows the results obtained with 10 cubic centimeters of HYC1 catalyst prepared in Example 2. The method of evaluating the catalyst followed the procedure described in Example 1.

[0083] It can be seen that the hydrodesulfurization activity (HDS) of the HYC1 catalyst is moderate, and when the temperature increases from 300 °C to 360 °C, its HDS activity also increases (between 86.3% and 96.2%). The hydrodesulfurization activity of the HYC1 catalyst is slightly lower than that of the commercially available catalyst (HDT1), especially at low temperatures, and their activities are similar at high temperatures. The olefin hydrogenation (HDO) of this catalyst is also moderate, and the initial olefin content is maintained at about 40%. But compared with HDT1 catalyst, HYC1 catalyst can reduce the average molecular weight of normal paraffin oil, and it will decrease with the temperature rising from 300℃ to 360℃. This indicates that the HYC1 catalyst has a very import...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com