Dyeing and spinning method for loose cotton fiber

A technology of loose fiber and cotton, which is applied in the spinning field of cotton loose fiber after dyeing, can solve the problems of yarn dyeing, piece dyeing defective products, repeated processes, time-consuming, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0040] Select 100 kilograms of sawtooth cotton, put the cotton into a solution with a liquor ratio of 1:12 and 2.8 grams per liter of water refining agent (LOS-2) at room temperature, raise the temperature to 95°C and keep it warm for 65-80 minutes, and let go of all the feet. water, wash with water.

[0041] Sulfur dyes are used, plus soda sulfide, the amount of sulfide soda is 1.5 times that of sulfur dyes, and 2-3% soda ash of the amount of sulfur dyes. In the dye liquor of demineralized water, the dyeing bath ratio is controlled at 1:20. The cotton was hung into the above-mentioned dye solution with an initial temperature of 40°C for 10 minutes, then added 6% sodium bicarbonate, and after 10 minutes, the temperature was raised to 90°C at a rate of 1°C per minute, and then dropped to 90°C after 60 minutes of heat preservation. Drain all the foot water at 70°C, change the water to wash, because the oxidation speed of sulfur red brown B3R is slow after dyeing, it is necessary...

example 2

[0042] Example 2: Spinning with the loose cotton prepared in the steps of Example 1

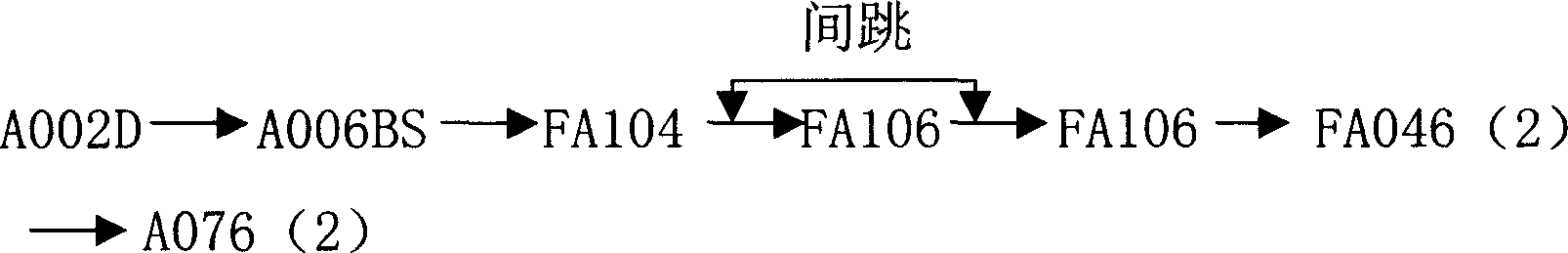

[0043] In the cotton cleaning step, the main beater speed is:

[0044] A002D 700 rpm, A006BS 430 rpm,

[0045] FA106 500 rpm, FA046 429 rpm, A076 920 rpm;

[0046] Gauge: A006BS: beater to dust bar in ~ out 15 ~ 18, dust bar and dust bar 12;

[0047] FA104: Cotton stripping knife to beater 2;

[0048] FA106: Roller to beater 8, stripping knife to beater 2, beater to dust stick in~out

[0049] 12~18;

[0050] A076: Cotton stripping knife to beater 2, beater to dust stick in~out 8~18.

[0051] The speeds of the main components during the carding step are:

[0052] Cylinder: 356 rpm, doffer: 18.6 rpm, licker-in roller: 922 rpm;

[0053] Gauge: small leak bottom and licker-in roller: in-out 1.5-0.7,

[0054] Cotton feeding board ~ licker-in roller: 7,

[0055] Licker-in cylinder: 7.

[0056] The draft ratio is about 28 in the spinning step;

[0057] The lin...

example 3

[0058] Example 3: Preparation of B1030S / 1

[0059] Cotton cleaning: mixed color cotton black / white 50 / 50 cotton pile mixed cotton, lap weight 360 g / m, natural color cotton lap weight 360 g / m

[0060] Carding: the weight of raw sliver is 16.8 grams

[0061] Gray Yubin: gray raw strips 16.8*8 12.6 grams

[0062] Essence: Bai Shengtiao 16.8*6+ Hui Yu 12.6*2 16.0

[0063] rejoin

[0064] Mixed combed slivers 19.5

[0065] Roving: Weight 5 grams Viscosity coefficient 110

[0066] Spun yarn: the draft ratio is about 28, and the standard weight is 1.96g / 100m

[0067] Winding: line speed 1100-1200 m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com