Re-scouring-free dyeing method for polyester woven fabric

A dyeing method and technology of polyester, which is applied in the field of non-repeat dyeing of polyester woven fabrics, can solve the problems of increasing printing and dyeing costs, achieve the effects of improving the first-time success rate, reducing pulp spots, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: the dyeing method of polyester woven fabric exempting from retraining, comprises the following steps:

[0040] S1: 500kg of cationic pongee open-width desizing, directly into the vat, and add water, the bath ratio is 1:10;

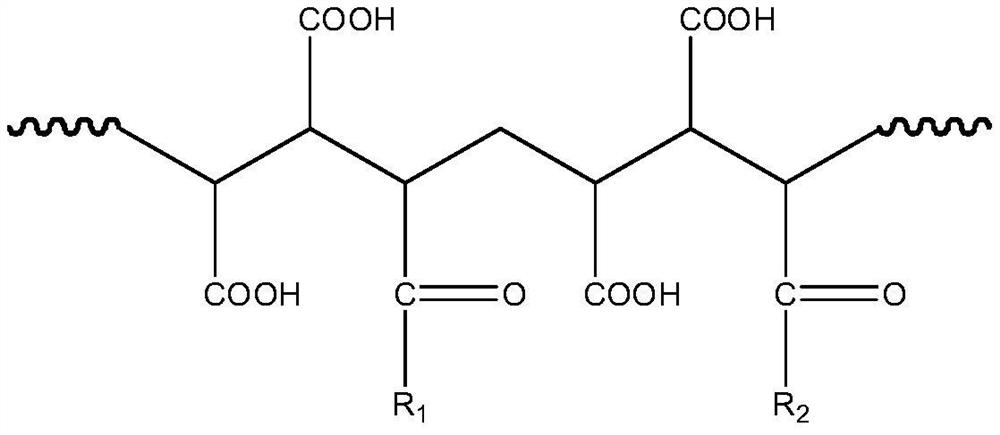

[0041] S2: Slowly add 5kg of non-retraining auxiliary agent into the machine cylinder, and run for 10 minutes after the feeding is completed, so that the non-retraining auxiliary agent is fully diluted, fully neutralizes the residual alkali, and disperses impurities such as cloth surface slurry and oligomers , the retraining-free auxiliary agent is a 1:1 (mass ratio) compound of polyacrylic acid series multi-polymer and polyester surfactant.

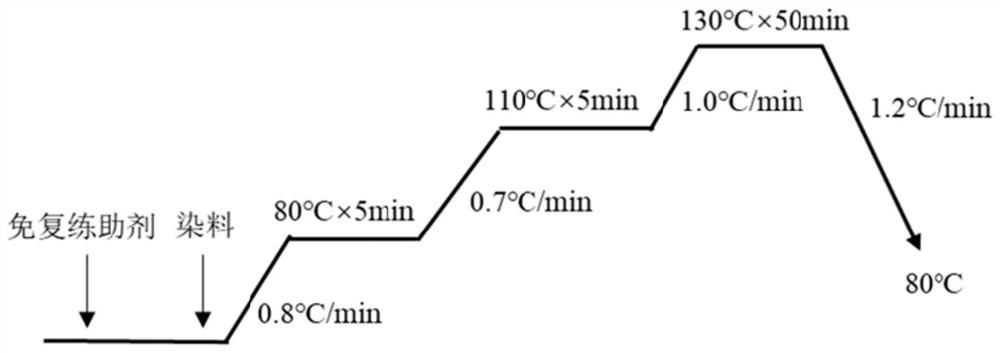

[0042] S3: Add 5kg of Disperse Brilliant Blue 2BLM warm water chemical into the vat for high temperature and high pressure dyeing. The dyeing heating curve is as follows figure 1 shown.

[0043] S4: Add 2g / L acid reduction cleaning agent and keep warm for 15-20min to remove floating color on th...

Embodiment 2

[0045] Embodiment 2: the dyeing method of polyester woven fabric exempting from retraining, comprises the following steps:

[0046] S1: After desizing 600kg polyester taffeta open width, it is directly put into the vat, and water is added, the liquor ratio is 1:8.

[0047] S2: Slowly add 6kg of non-retraining auxiliary agent into the machine cylinder, and run for 10 minutes after the feeding is completed, so that the non-retraining auxiliary agent is fully diluted, fully neutralizes the residual alkali, and disperses impurities such as cloth surface slurry and oligomers. The retraining-free auxiliary agent is a 3:1 (mass ratio) compound of polyacrylic acid series multi-polymer and polyester surfactant.

[0048] S3: Add 8kg of disperse Cuilan S-GL warm water chemical into the vat for high temperature and high pressure dyeing. The dyeing temperature rise curve is as follows figure 1 .

[0049] S4: Add 3g / L acid reduction cleaning agent, keep warm for 15-20min, and remove floatin...

Embodiment 3

[0051] Embodiment 3: the dyeing method of polyester woven fabric free from retraining, comprises the following steps:

[0052] S1: After 500kg of mycetin is desized in the open width, put it directly into the vat, and add water, the liquor ratio is 1:10.

[0053] S2: Slowly add 8kg of non-retraining auxiliary agent into the machine cylinder, and run for 10 minutes after the feeding is completed, so that the non-retraining auxiliary agent is fully diluted, fully neutralizes the residual alkali, and disperses impurities such as cloth surface slurry and oligomers. The retraining-free auxiliary agent is a 2:1 (mass ratio) compound of polyacrylic acid series multi-polymer and polyester surfactant.

[0054] S3: Add 5kg of Sancuilan S-GL warm water chemical into the vat for high temperature and high pressure dyeing. The dyeing temperature rise curve is as follows: figure 1 .

[0055] S4: Add 3g / L acid reduction cleaning agent, keep warm for 15-20min, and remove floating color on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com