Concrete pipe manufacturing equipment and method

A technology for concrete pipes and manufacturing equipment, used in life-saving equipment, other equipment, manufacturing tools, etc., can solve the problems of inability to accurately control the speed relationship, inability to control sufficiently accurately, and inapplicability, and achieve easy connection and separation. Increase and avoid errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

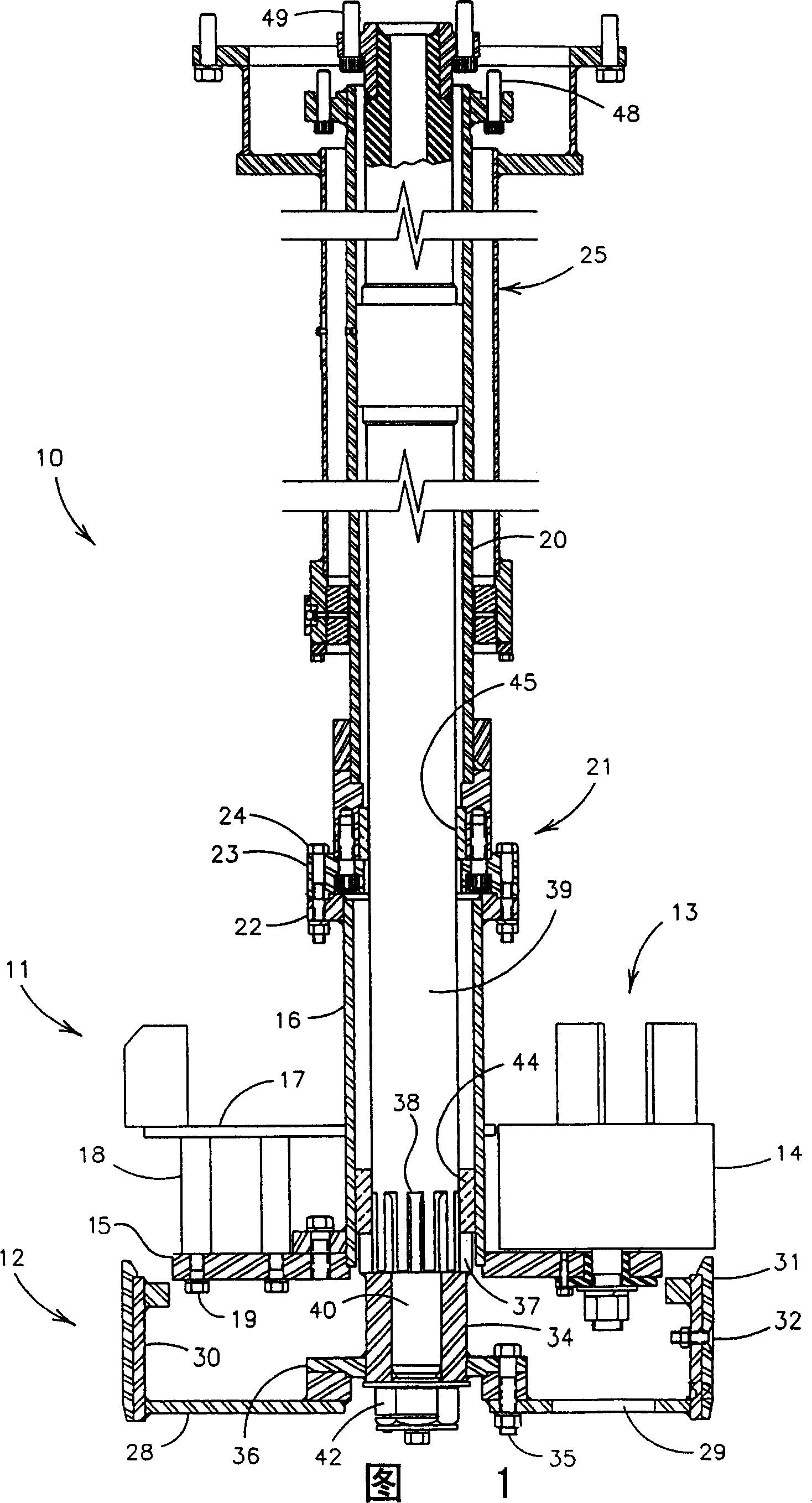

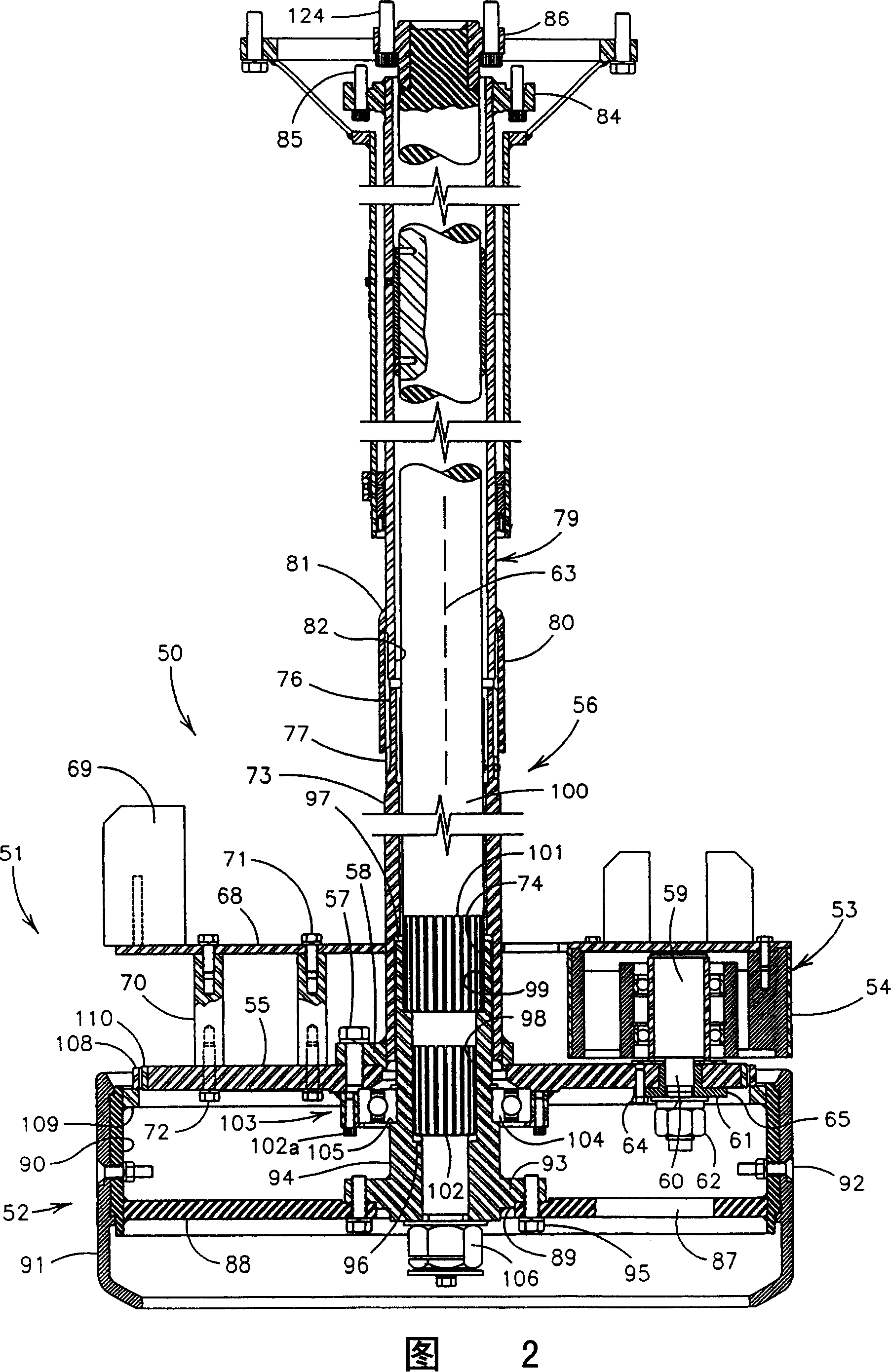

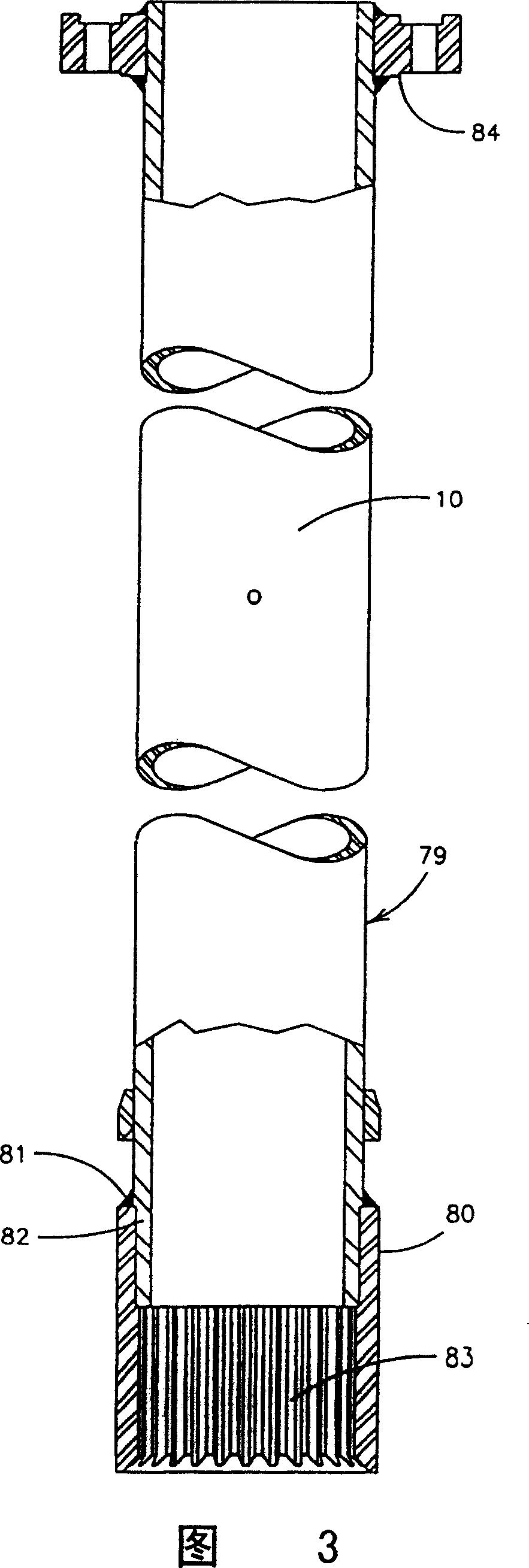

[0016] Please refer to Fig. 1, an existing reverse filling head assembly (hereinafter referred to as filling head) is represented by 10, and this filling head comprises a roller assembly represented by 11, or simply referred to as a roller head, and A trowel assembly generally referred to as a trowel and indicated at 12.

[0017] The roller head 11 includes a roller assembly indicated by 13 , and the roller assembly 13 includes a plurality of smoothing rollers, usually four, and one of the smoothing rollers is indicated by 14 . The roller 14 is supported by a roller mounting plate 15 , and the roller mounting plate 15 is connected with the lower driving tube 16 . A roller cage occupied between the rollers 14 is indicated at 17, the function of this roller cage is to intercept wet concrete from above before it falls below the top of the rollers 14 and also to ensure that the wet concrete The flow is radially outward to the inner wall of the mold, not shown. The roller cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com