Wall finishing panel system

a wall and panel technology, applied in heat-insulating, natural mineral layered products, other domestic objects, etc., can solve the problems of reducing the performance of the associated masonry wall system, reducing the insulating efficiency, and frost spalling, so as to improve the performance and versatility of the insulation system, and increase the evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

fifth embodiment

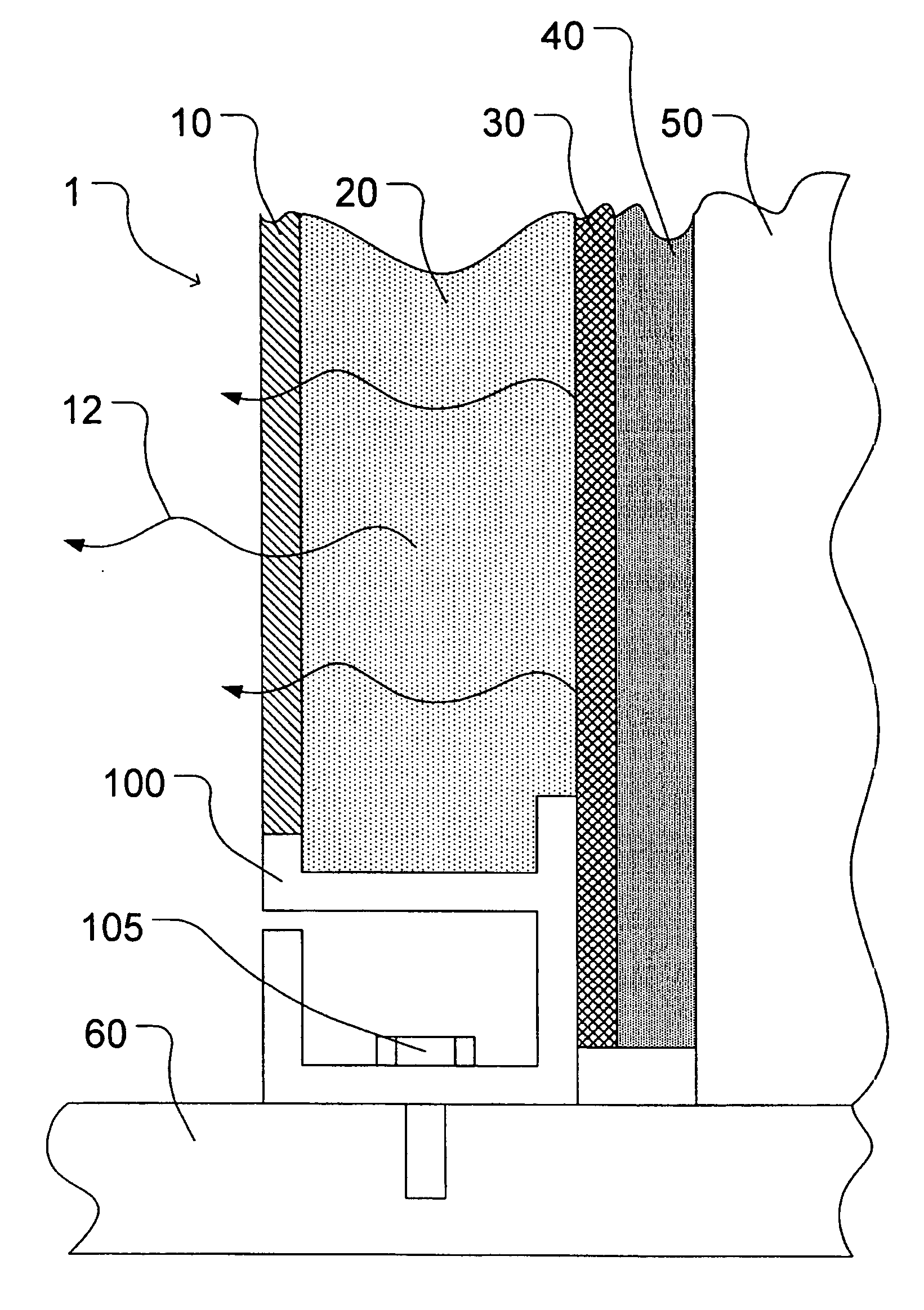

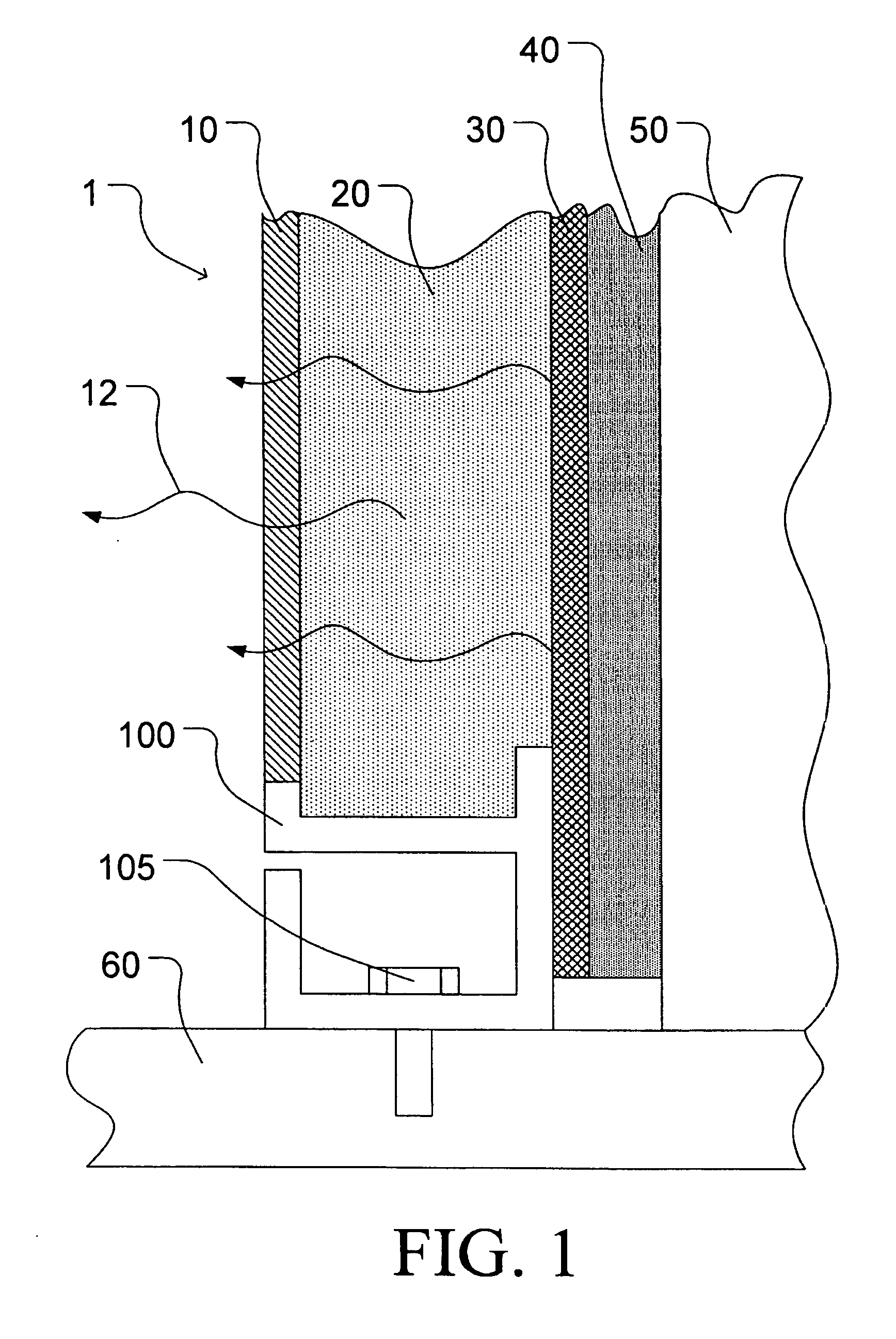

[0028] A fifth embodiment is illustrated in FIG. 5 in which a wicking layer 45 has been incorporated into the insulating system generally illustrated in FIG. 4. This embodiment would have particular utility for insulating below grade masonry walls or other exterior walls that are expected to reach temperatures below the dew point of the air enclosed within the finished space and / or may continuously or periodically extrude or seep moisture. The wicking material is arranged to collect and transport any such liquid, whether seepage or condensate, from the interface between the wall and the insulating system to an exposed area 45a that will allow for evaporation or other removal means and thereby prevent or reduce any significant collection of liquid at the interface.

sixth embodiment

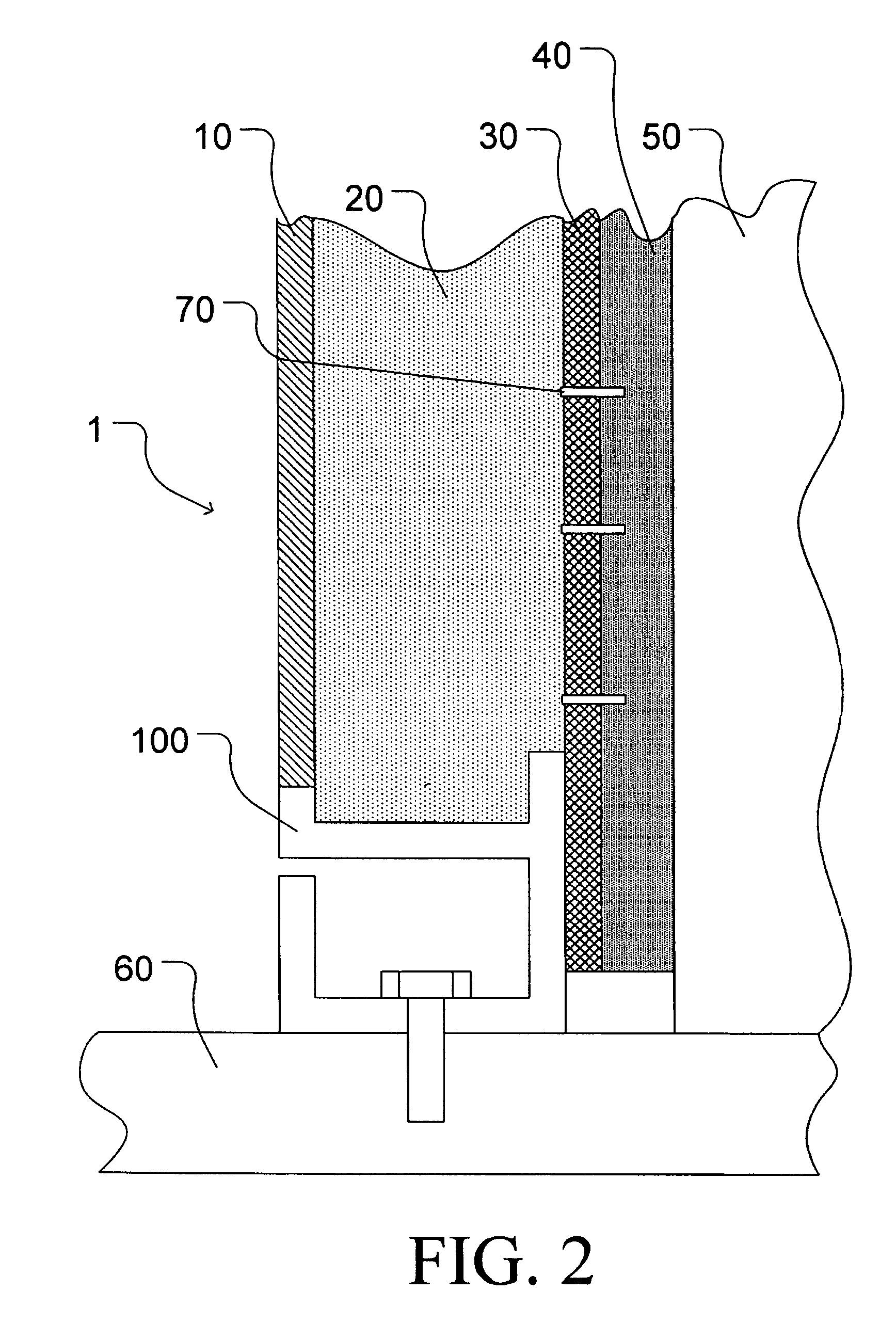

[0029] A sixth embodiment is illustrated in FIG. 6 wherein the supporting structure or base 100 is attached to the wall 50 with a fastener 105 and / or an adhesive (not shown). The base 100 is configured to receive an external trim, fascia or finish piece 102 that can be configured to provide external openings or vents 106 for improving the evaporation of collected and transported liquid from the terminal portion 45a of the wicking layer 45 and may have an extension 104 that is configured to establish a friction fit with the base structure 100 that will tend to hold the terminal portion of the wicking layer in place. The base structure 100 may also provide one or more channels, guides or races 44 for communication cable, networking cable and / or power cable distribution 46 concealed within the base structure while still keeping the cables readily accessible for reconfiguration.

[0030] As illustrated in FIGS. 7 and 8, the insulating system 1 may be used to finish walls 50 in new construc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flame retardant | aaaaa | aaaaa |

| Proximity effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com