Straight-line suppersonic motor based on vibration in rectangular piezoelectric ceramic thin plate

A technology of piezoelectric ceramics and ultrasonic motors, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve complex structure, large volume, electromechanical conversion efficiency and position low resolution issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

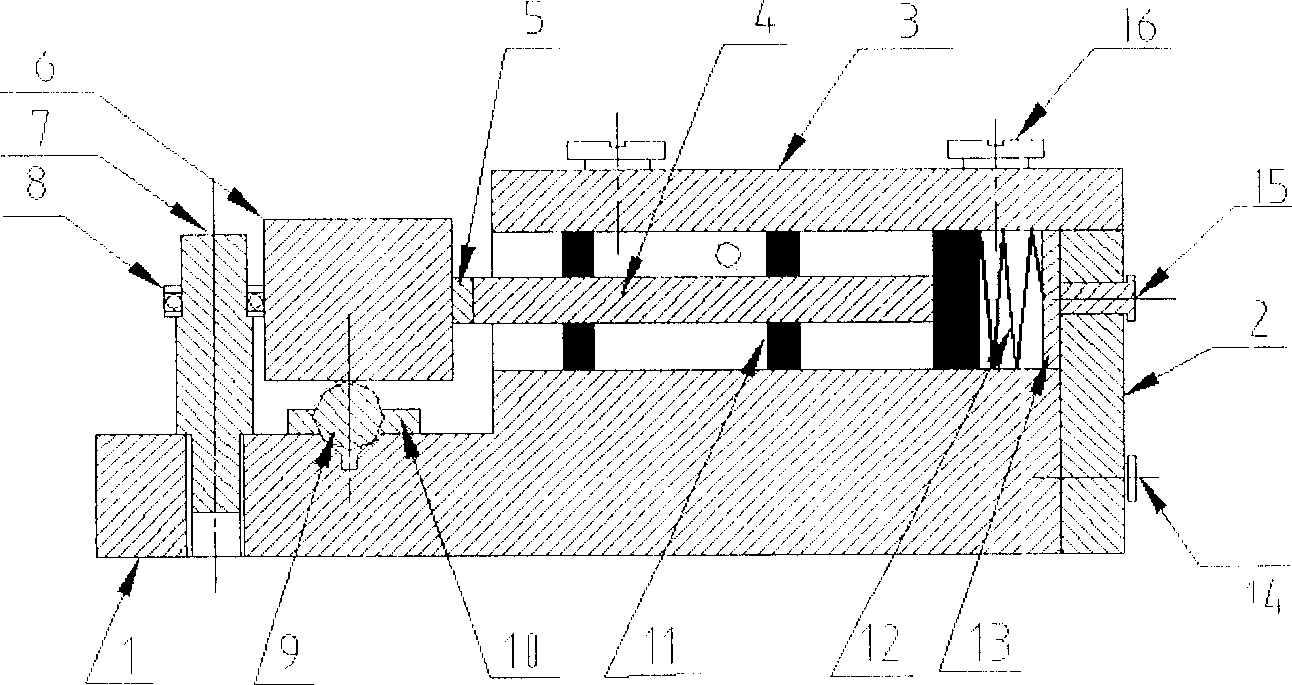

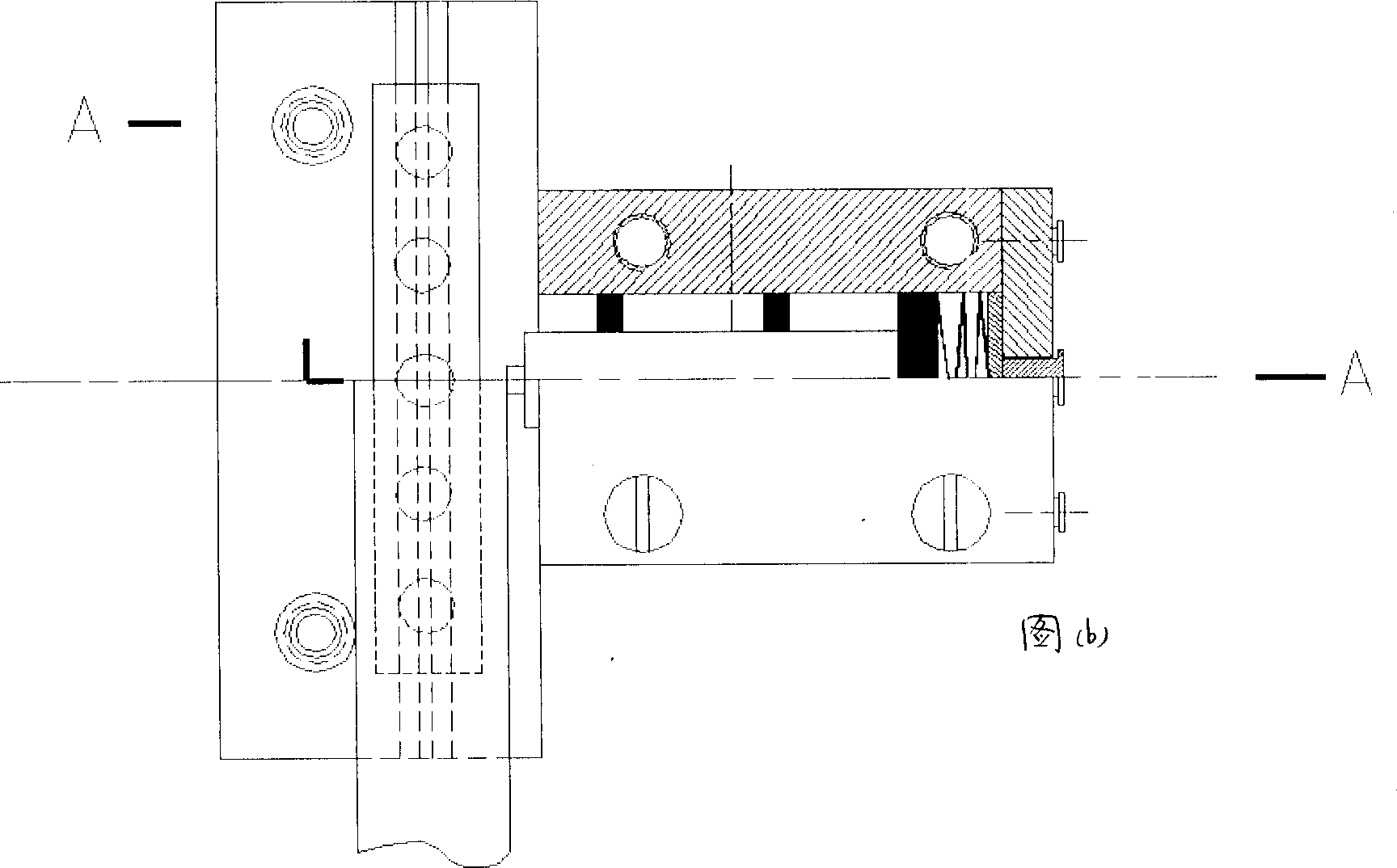

[0007] according to figure 1 and figure 2 Describe the specific embodiment and working principle of the present invention.

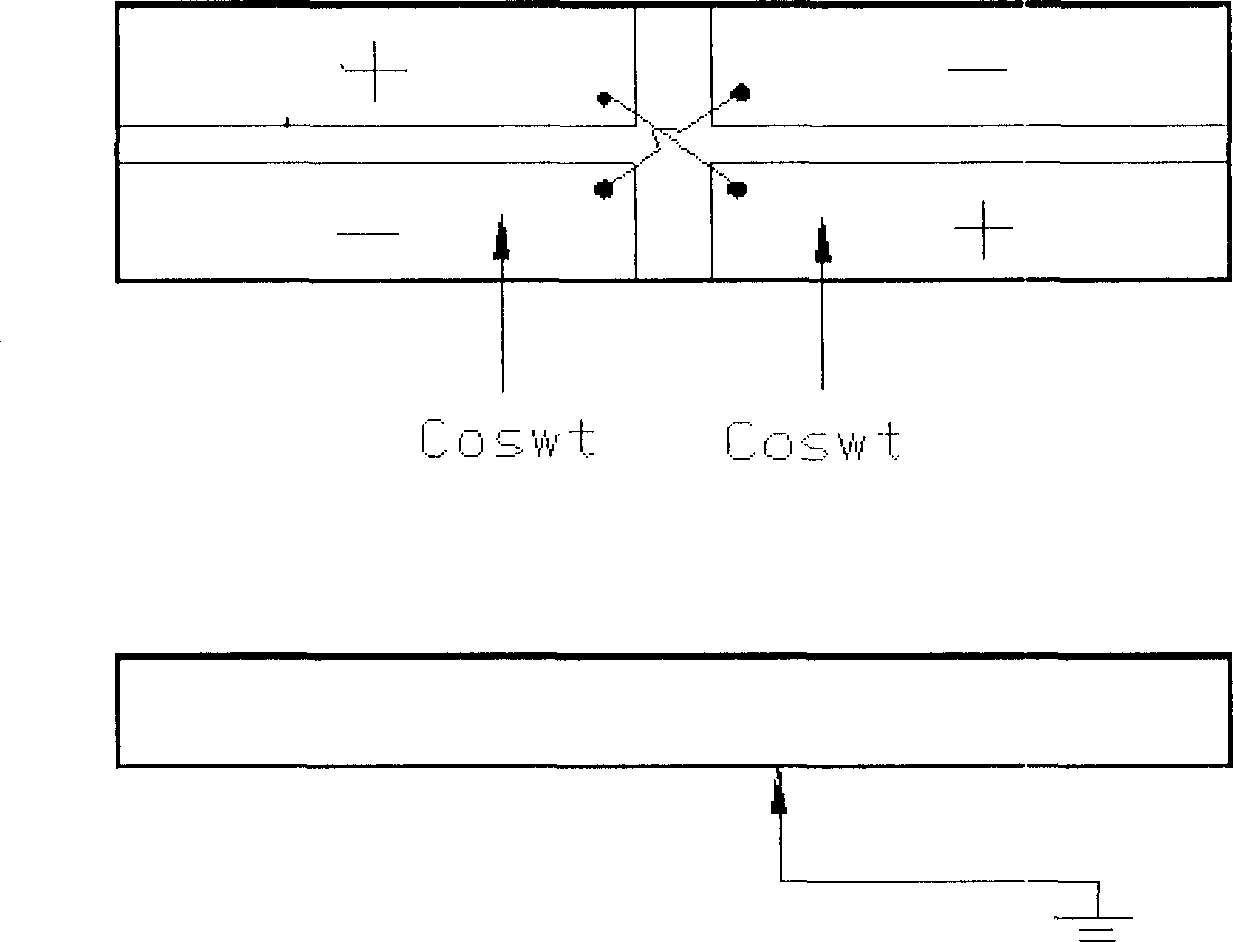

[0008] The rectangular piezoelectric ceramic thin plate 4 is fixed by the rubber sleeve 11, so as to better excite the required working modes. The protrusion 5 glued on the top of the rectangular piezoelectric ceramic thin plate 4 constitutes a composite drive vibrator (stator), thereby improving the contact between the stator and the mover 9 . The bearing 8 installed at the contact point of the mover guiding mechanism is used to guide the mover. Pins 9 are installed at the contact of the moving track of the mover to reduce the contact area between the mover and the moving track, thereby reducing the sliding frictional resistance of the mover 6 . The preload spring sheet 12, the preload washer 13, the preload screw 15, and the preload nut 14 constitute a preload adjusting device, which controls the preload applied to the vibrator (stator) by changing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com