Corn mass flow sensor

A sensor and grain yield technology, applied in the field of sensors, can solve the problems of reduced measurement accuracy and inability to measure grain mass flow, etc., and achieve the effects of simple overall structure, reduction of strong foundation vibration interference, and improvement of damping ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

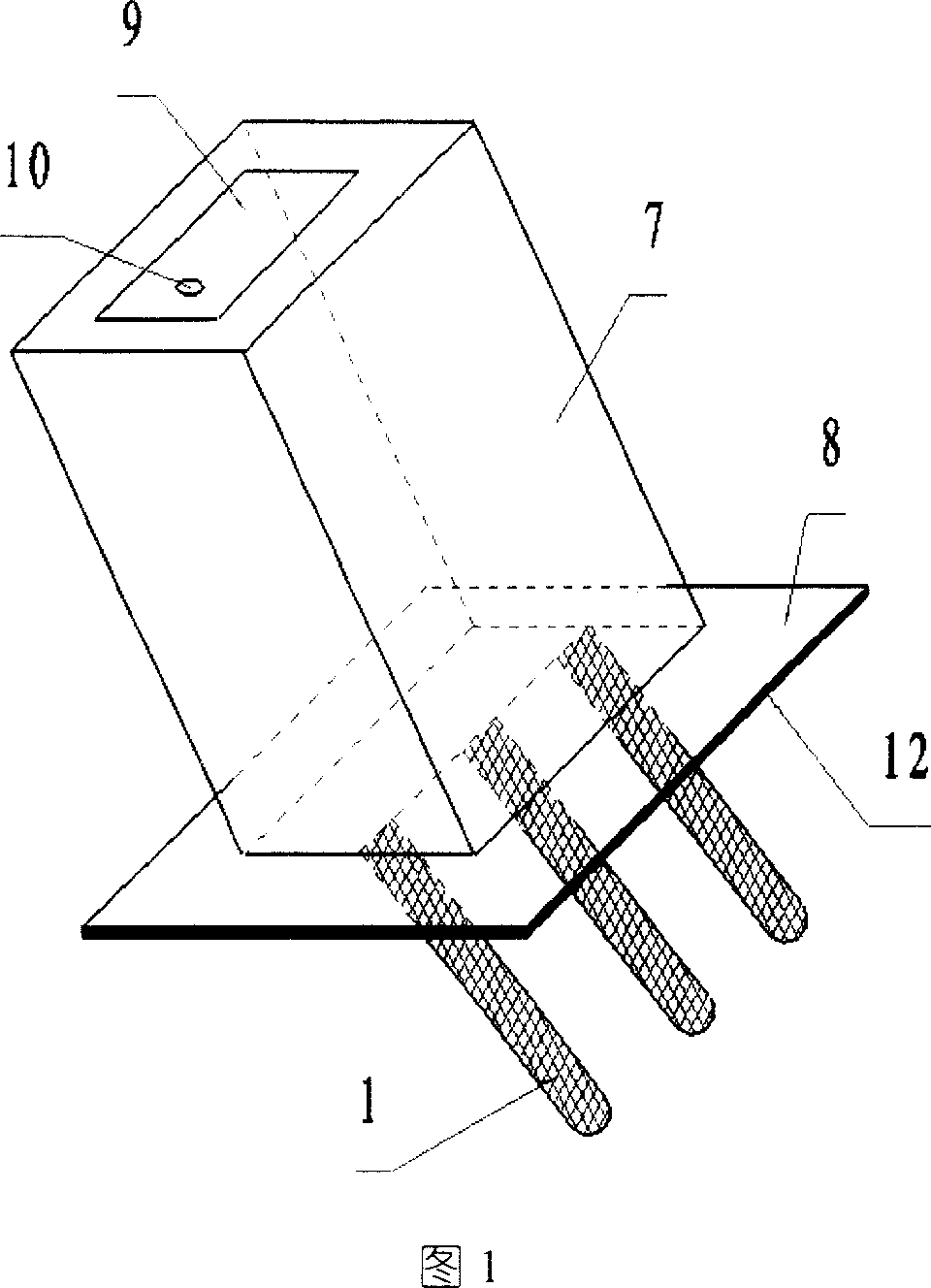

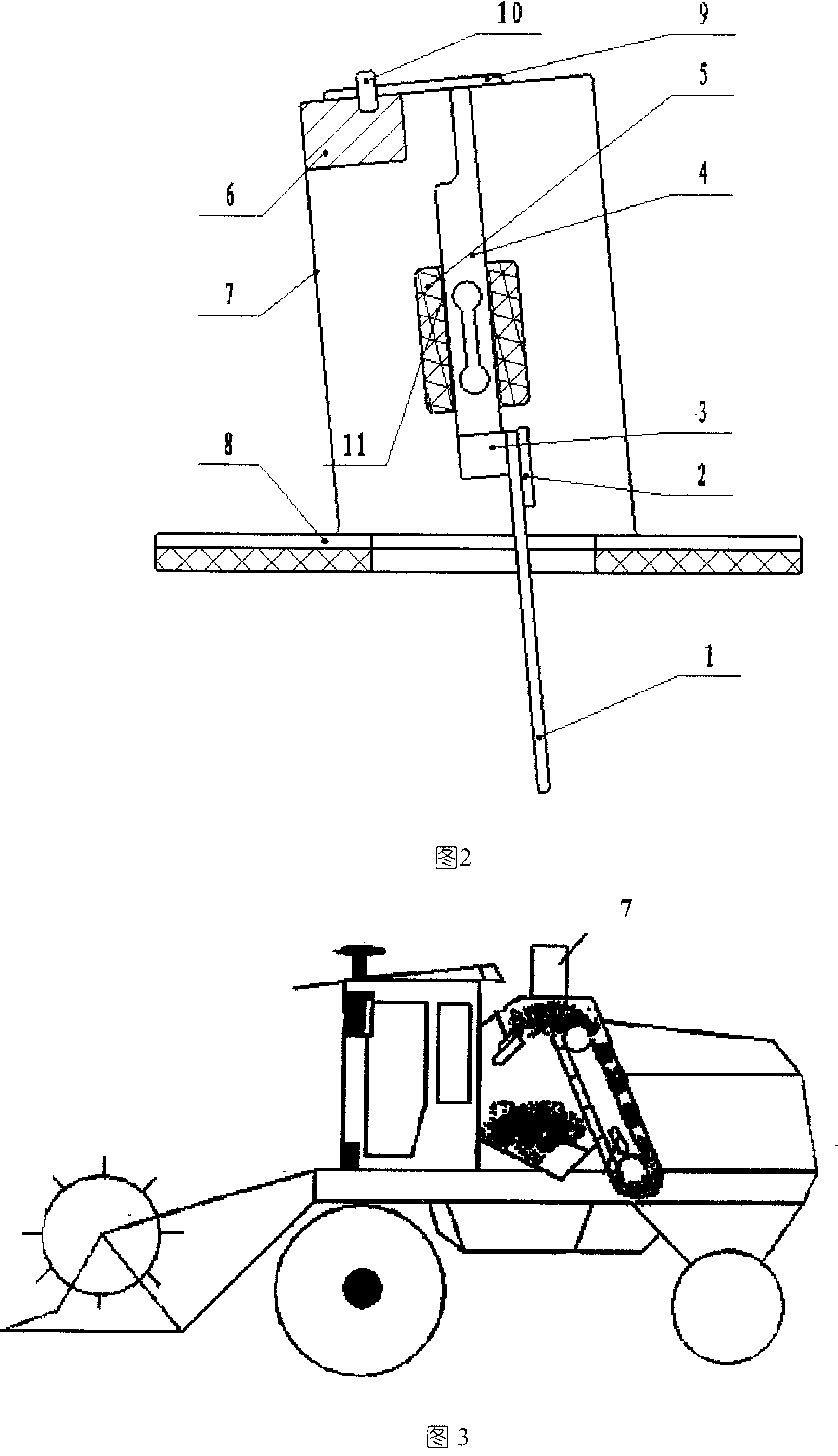

[0013] As shown in Figure 1 and Figure 2, the present invention includes: measuring finger 1, mounting plate 2, "door" shaped fixing frame 3, force measuring elastic element 4, dynamic vibration damping module 5, front-end signal transmission module 6, and housing 7 , Flange plate 8, cover plate 9, wiring socket 10, strain gauge bridge 11 and rubber pad 12. Among them, the measuring finger 1 is connected to one end of the force-measuring elastic element 4 through the mounting plate 2 and the “door”-shaped fixing frame 3, and the other end of the force-measuring elastic element 4 is fixed on the housing 7. The top of the shell 7 is a cover plate 9 and a wiring socket 10 fixed on the cover plate 9, and the bottom is a flange plate 8, and the rubber pad 12 is located between the flange plate 8 and the frame of the combine harvester. A front-end signal transmission module 6 is also arranged in the housing 7. The strain gauge bridge 11 is pasted on the elastic force measuring element 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com