Device for coating preparation on ceration fibre especially on eyebrow or eyelash

A keratin fiber, coating technology, applied in the field of "twisted brush" brush, coating device, can solve the problem of not being able to form a gradual form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

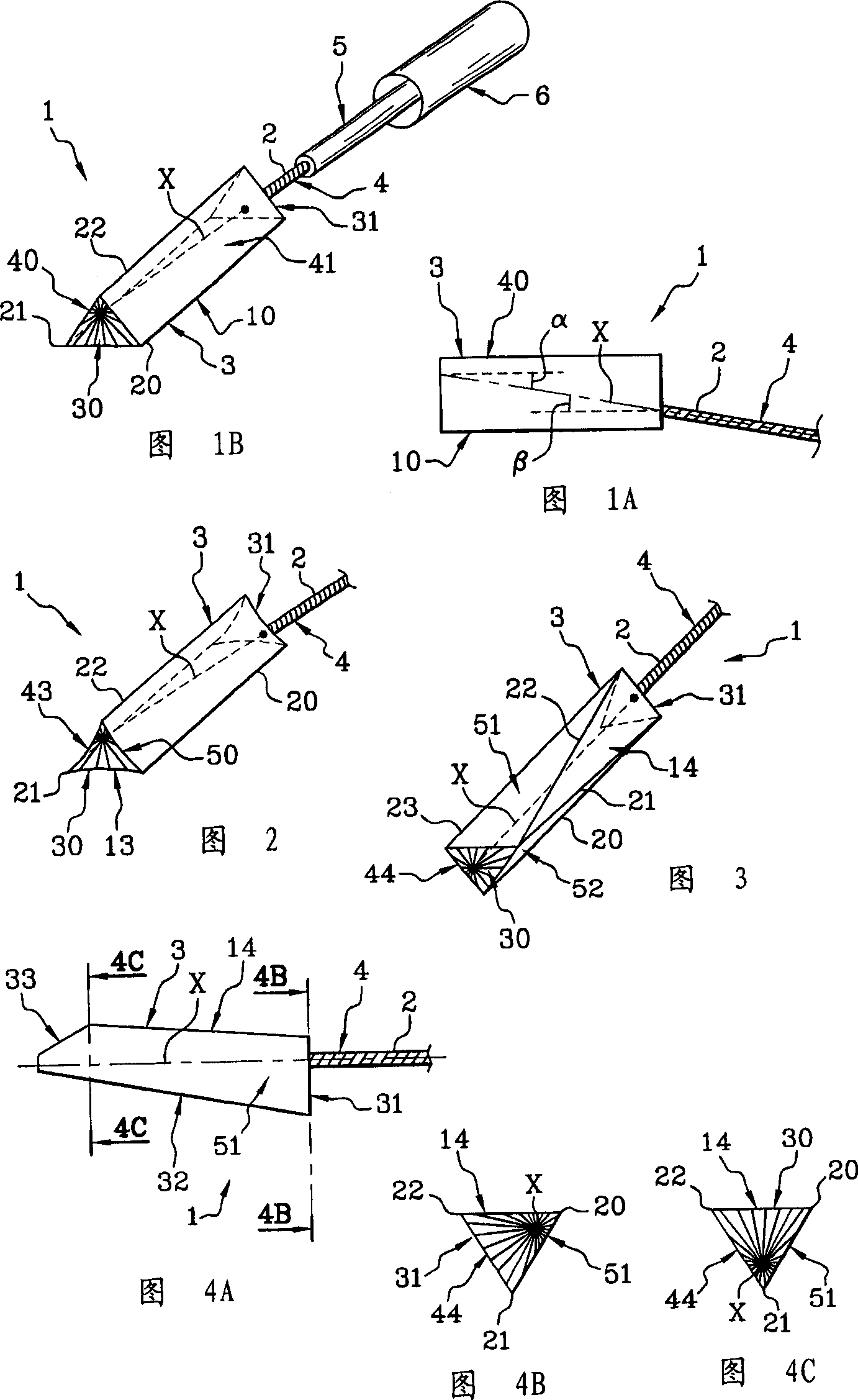

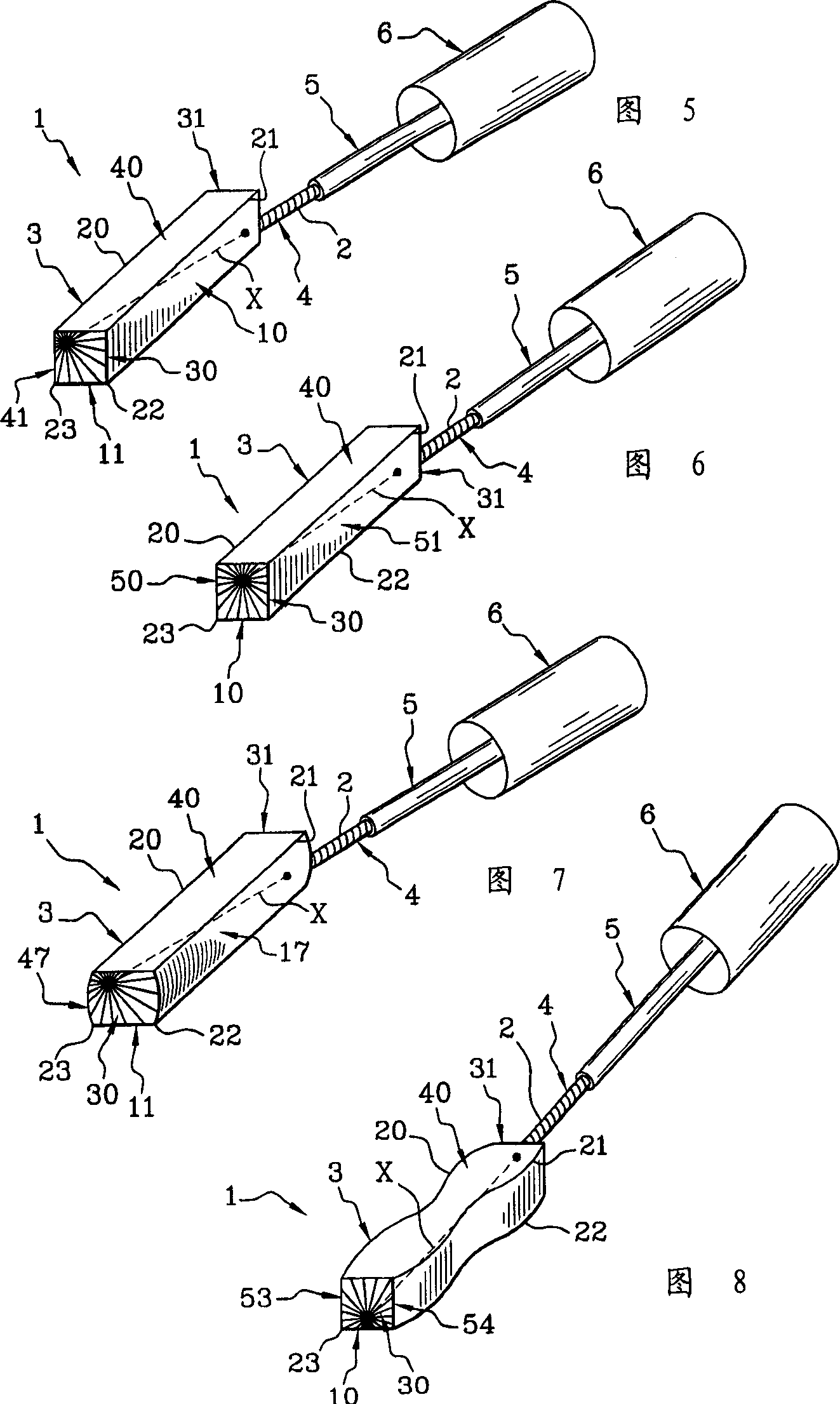

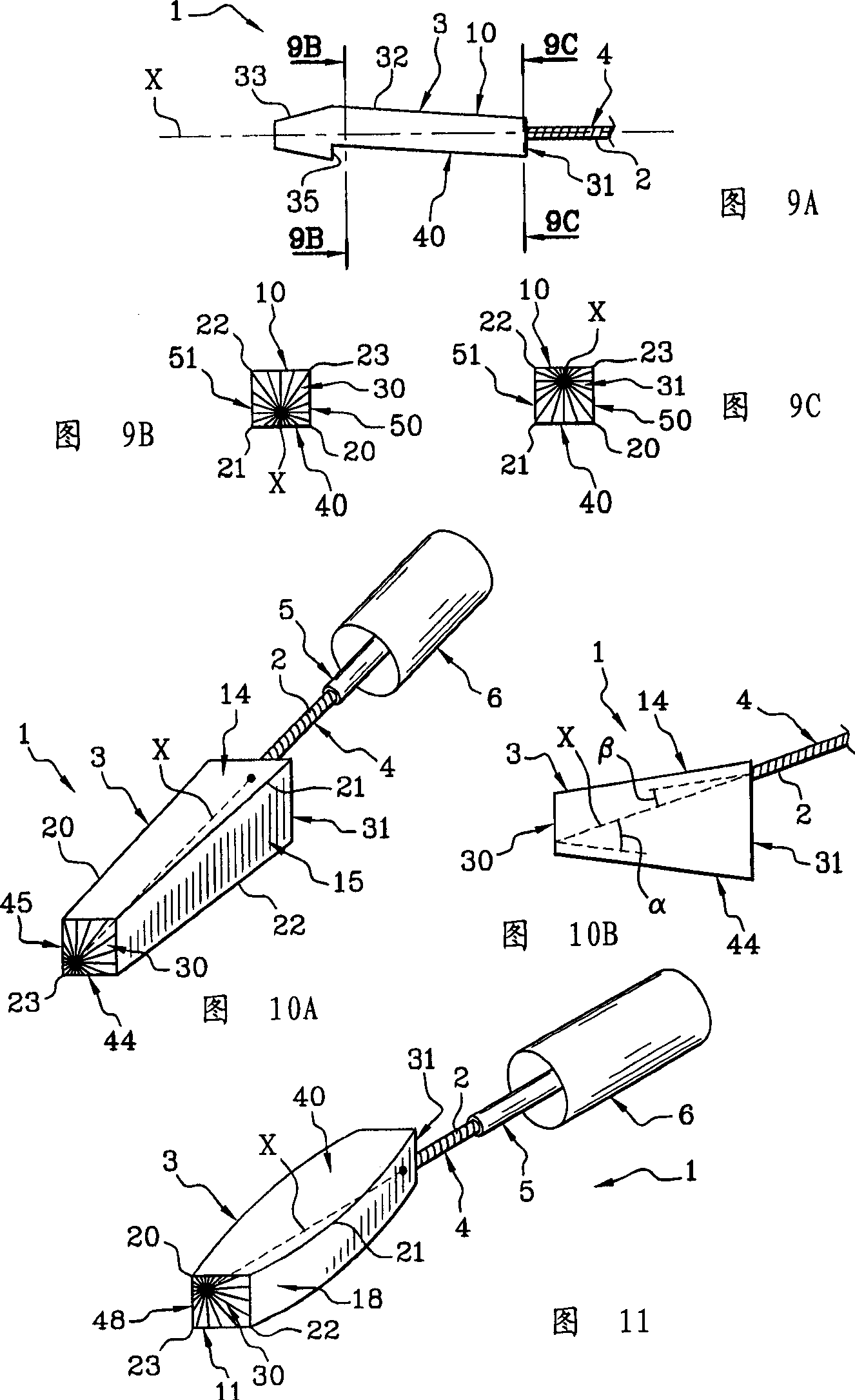

[0071] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

[0072] Figure 1A shows a brush 1 of square cross-section at a high level. The application portion of the device is numbered 3 . The axis X of the tail 4 of the brush forms an acute angle β with one surface 10 of the brush, the apex of which is directed towards the tail 4 . The axis X of the tail 4 of the brush 1 forms an angle α with the surface 40 of the brush opposite the surface 10 , the apex of which is remote from the tail 4 . The included angles α and β are approximately equal, so surfaces 10 and 40 are approximately parallel. The size of the included angles α and β is about 5°. The other two longitudinal surfaces are not marked, they are parallel to each other and to the axis X of the tail 4 . In the following description, reference numerals beginning with the numeral “1” refer to the surface forming an angle of the type “β” with the axis X and the apex of the angle facing the tail 4 by convention. The numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com