Installation distributing tool and multi-band lifting-clamping device

A clamping device and clamping device technology, applied in elevators, transportation and packaging, lifting equipment in mines, etc., can solve problems such as damage to steel strips, and achieve the effect of eliminating winding problems, reducing costs and saving installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

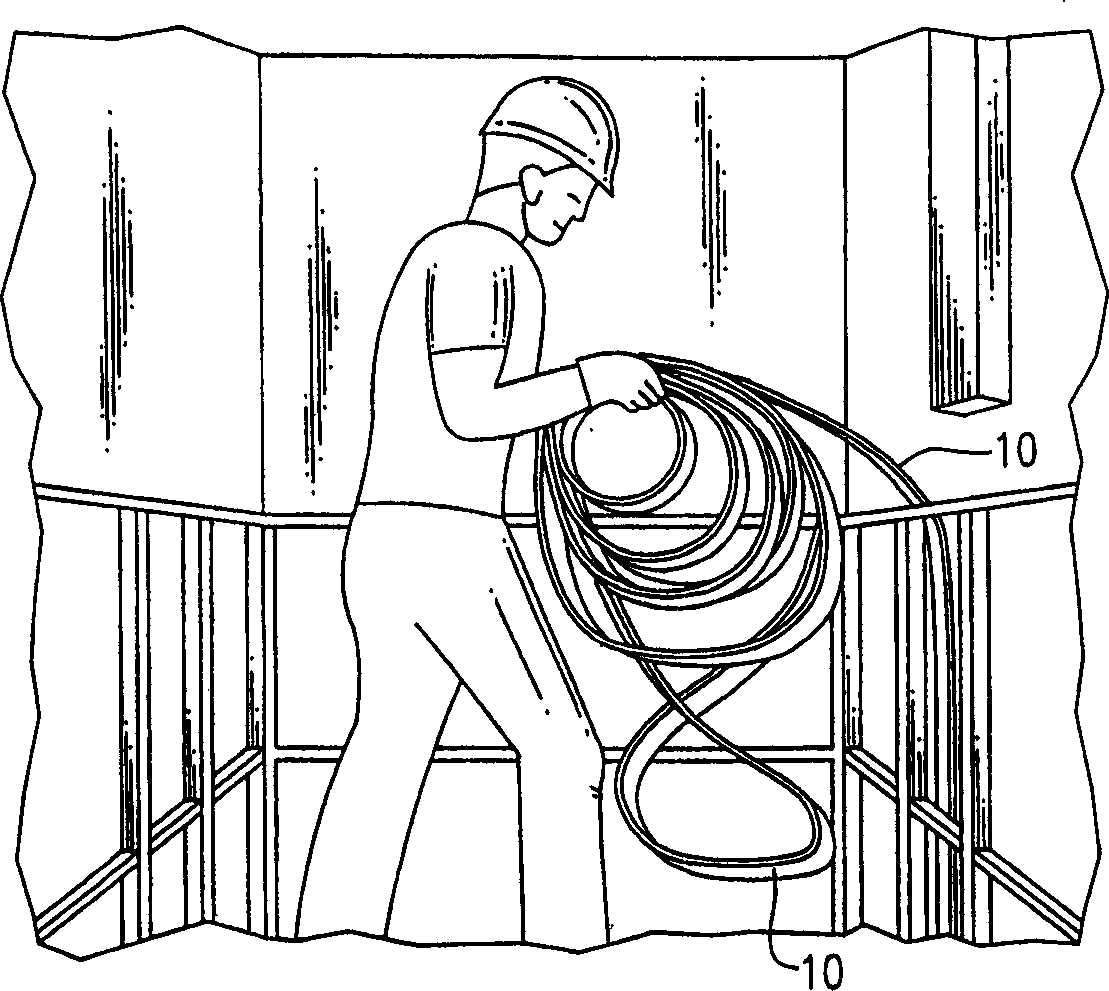

[0025] Referring to Figure 1, (Prior Art) As previously stated, Otis elevators have introduced into the technical field of elevator systems coated steel belts 10 that can be used as tension members. These new belts 10 are stronger and more flexible than conventional steel cables which have many advantages. Conventional methods for installing steel cables can also be used for installing the steel belt 10 . In particular, as shown in Figure 1, the steel belt is fed independently under the elevator shaft around one pulley and then over a second pulley, the ends of the belt being fastened to the At the second pulley.

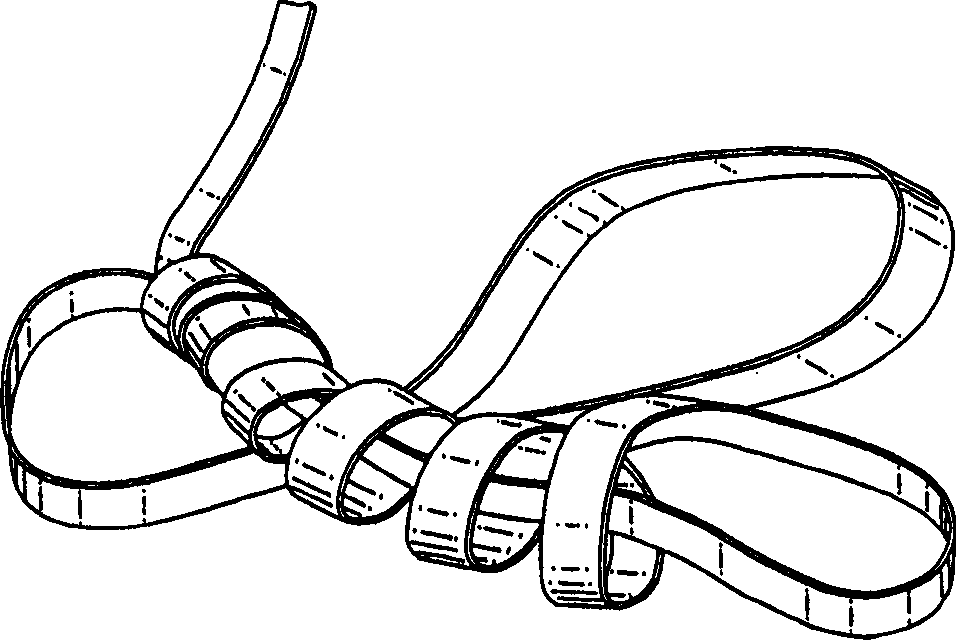

[0026] However, when such a new coated steel strip 10 is installed using conventional methods, the strip 10 is wound as shown in FIG. 2 (prior art).

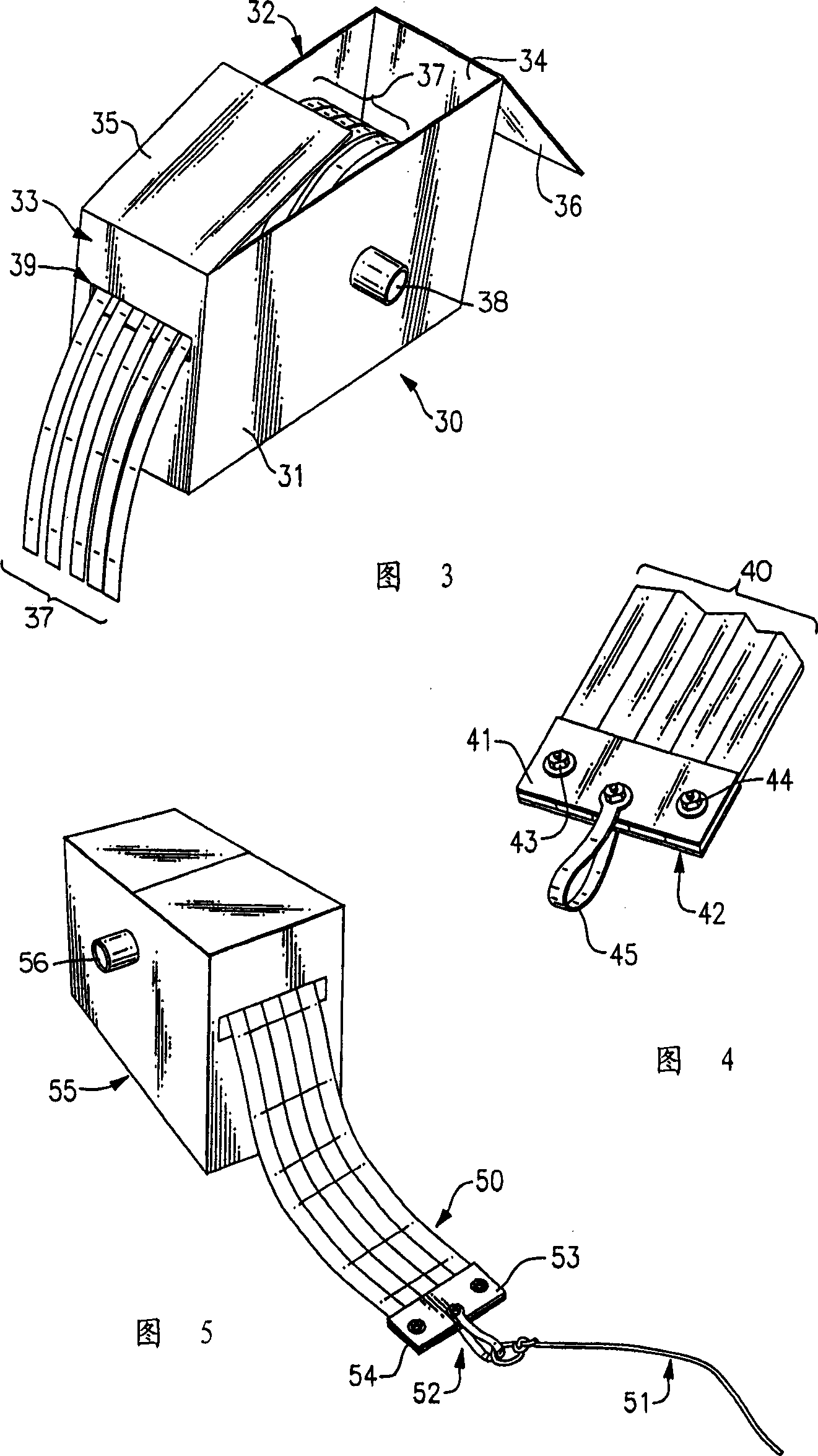

[0027] As shown in Figure 3, the box-type container includes a generally rectangular floor (not shown). A generally rectangular first side panel 31 and a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com