Vapor and microwave combined continuously cooking device

A microwave and steam technology, used in baking devices, household appliances, food preparation, etc., can solve the problems of difficult to obtain products with stable structure, surface drying, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] First, a method for continuous microwave cooking plus steam cooking in an oven will be described.

[0047] The role of microwave cooking is to quickly transfer energy to the inside of a spacer in the form of a volumetric ribbon in a fraction of the time to gel the proteins and cook the other ingredients.

[0048] The role of steam cooking is a supplement to cooking in order to obtain the required temperature for optimal cooking of the inside and outside.

[0049] By the method described, a supplemental energy different from microwaves is introduced, which can finally carry out cooking in the critical zone, from a temperature of 65-75°C to the desired temperature of 75-90°C inside the mass.

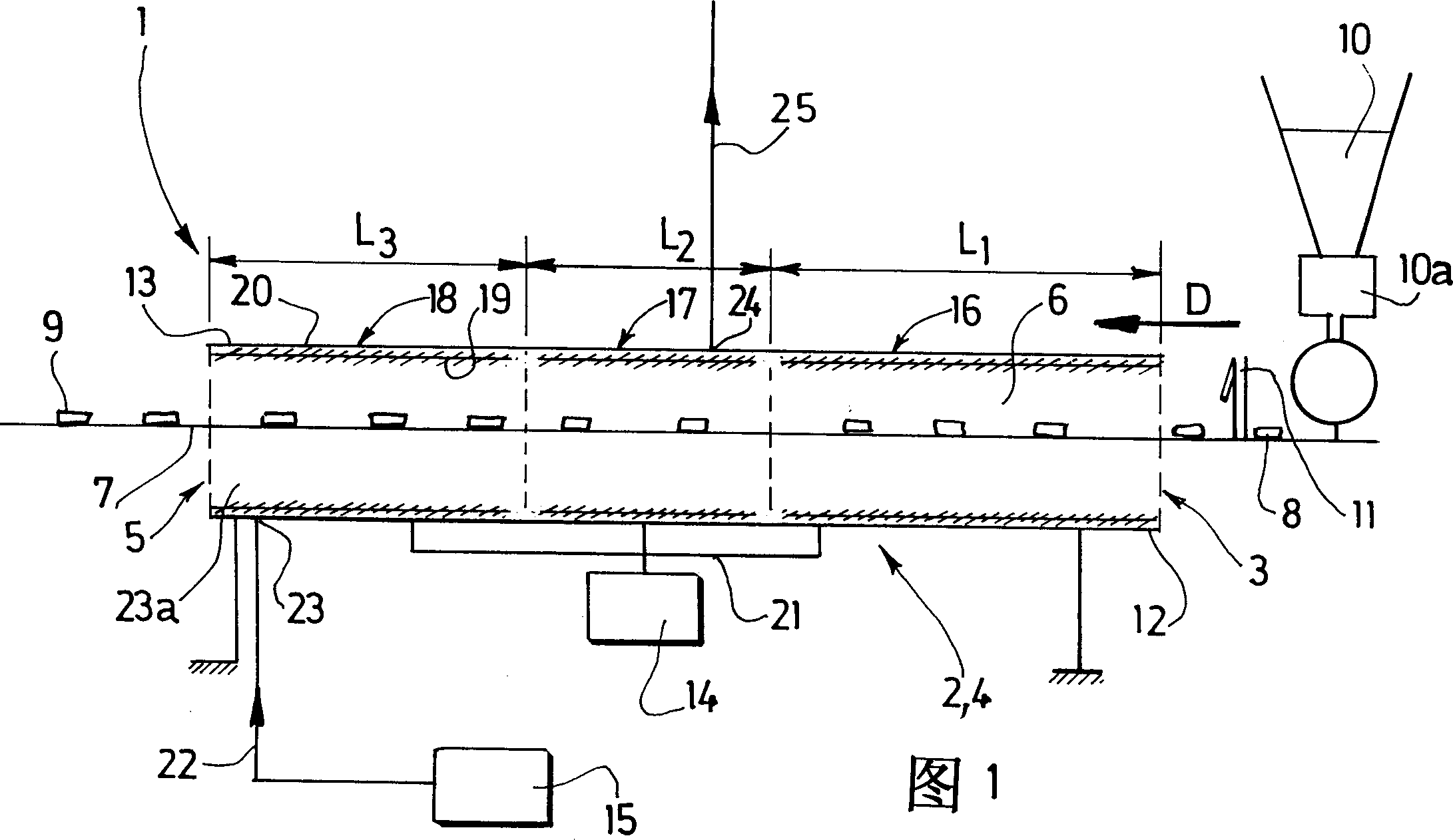

[0050] The device 1 used in the method comprises equipment for processing the material to be cooked, which equipment includes a furnace 2 . The furnace 2 comprises an inlet zone 3 , a cooking zone 4 and an outlet zone 5 . The cooking zone comprises a vessel 6 forming a cooking cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com