Apparatus for air treatment and transportation of a material

A technology of air and conveying direction, which is applied in the field of equipment used for material air treatment and conveying, which can solve the problems of expensive manufacturing and difficult cleaning of the device, and achieve the effect of cheap manufacturing and maintenance and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

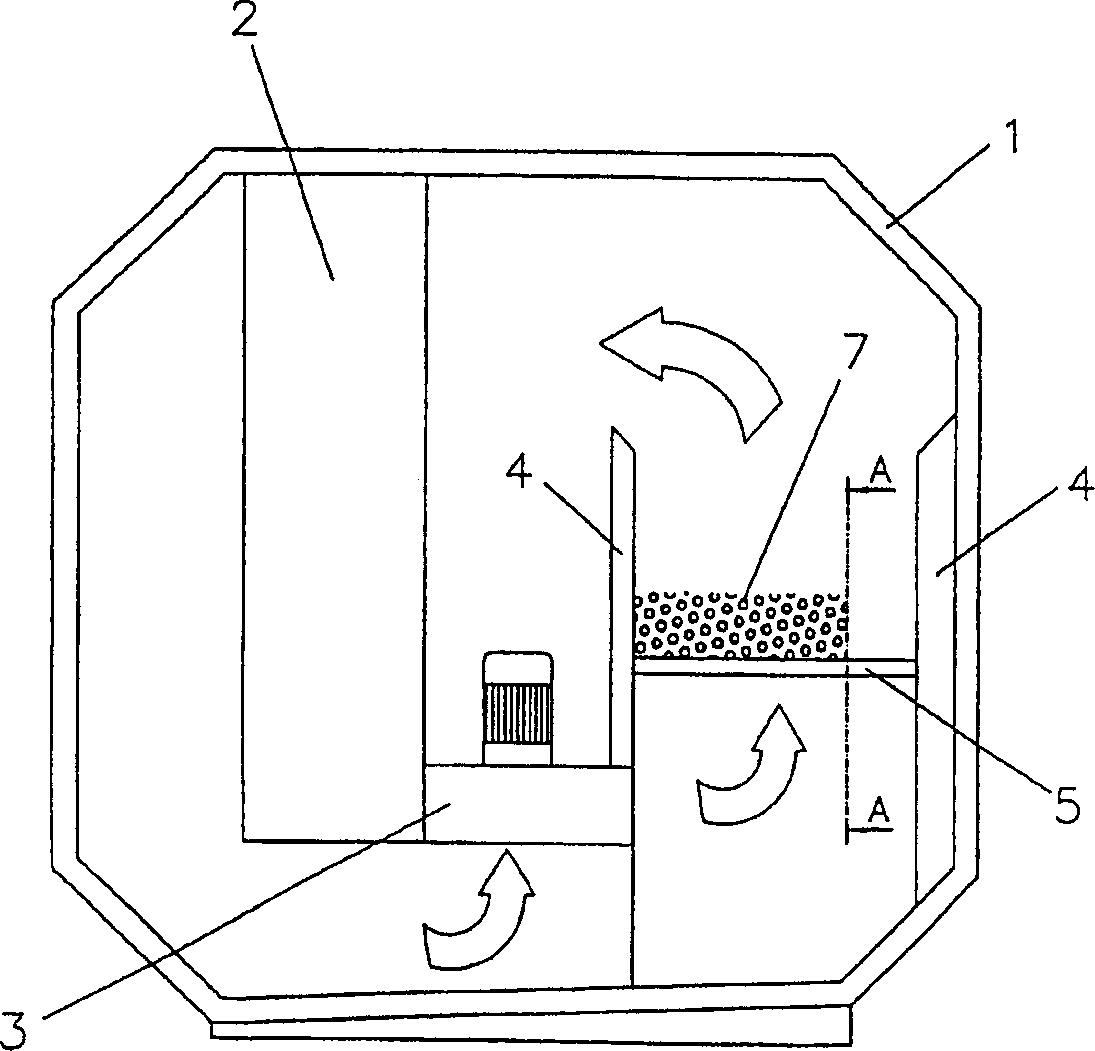

[0029] exist figure 1 In the arrangement shown, the insulating housing is identified as 1 . The material 7 passing through the device, ie in the example the food to be frozen, passes through the device as a layer above the perforated trough bottom 5 in a direction perpendicular to the plane of the drawing. The air flow for at least partial fluidization of the material layer is generated by one or more fans 3 . The air flow passes through the tank bottom 5 , through the material 7 and further through one or more cooling batteries 2 . In the cooling tank the air temperature is reduced, after which the air is again passed through the fan and further through the tank bottom and the material.

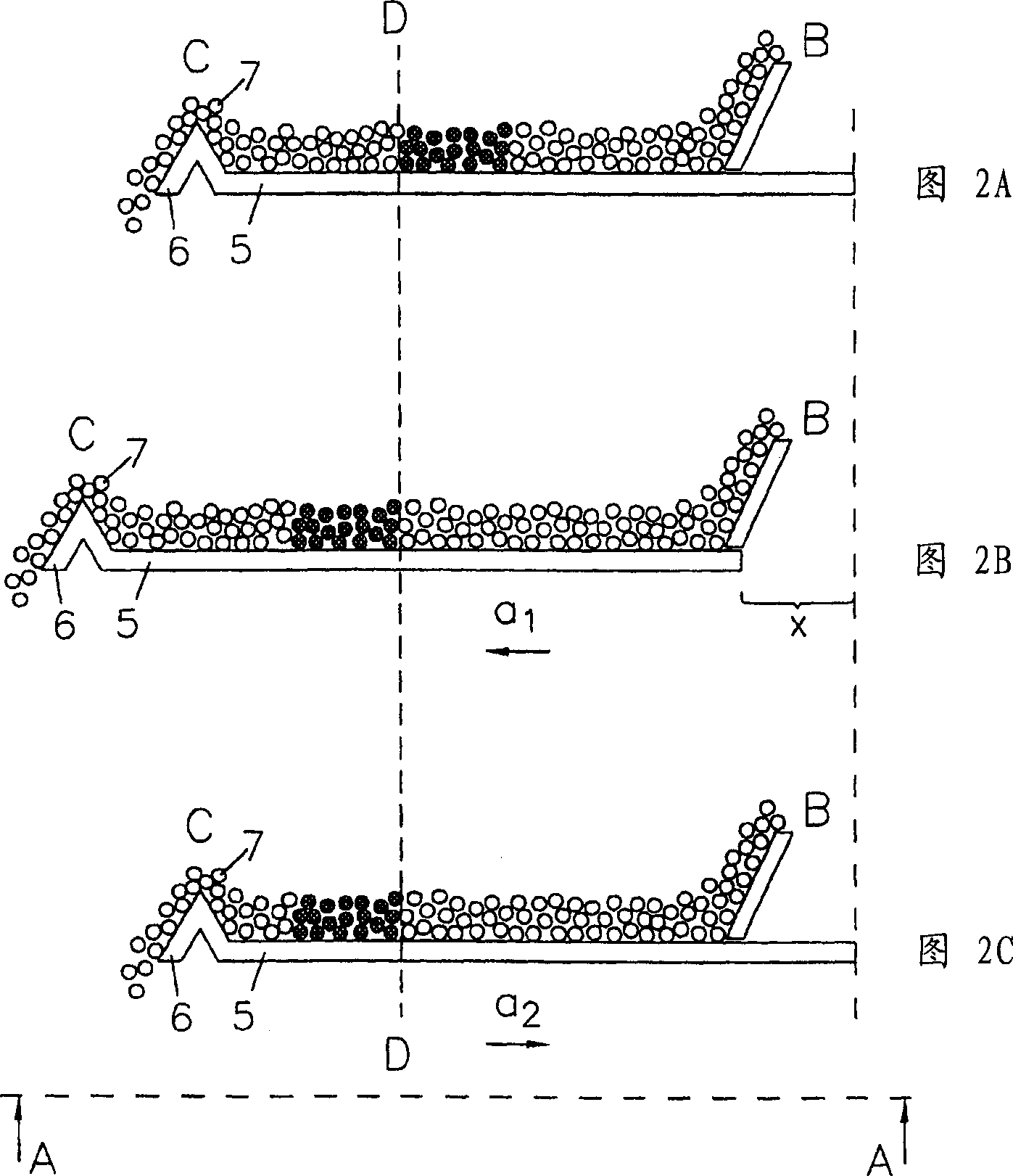

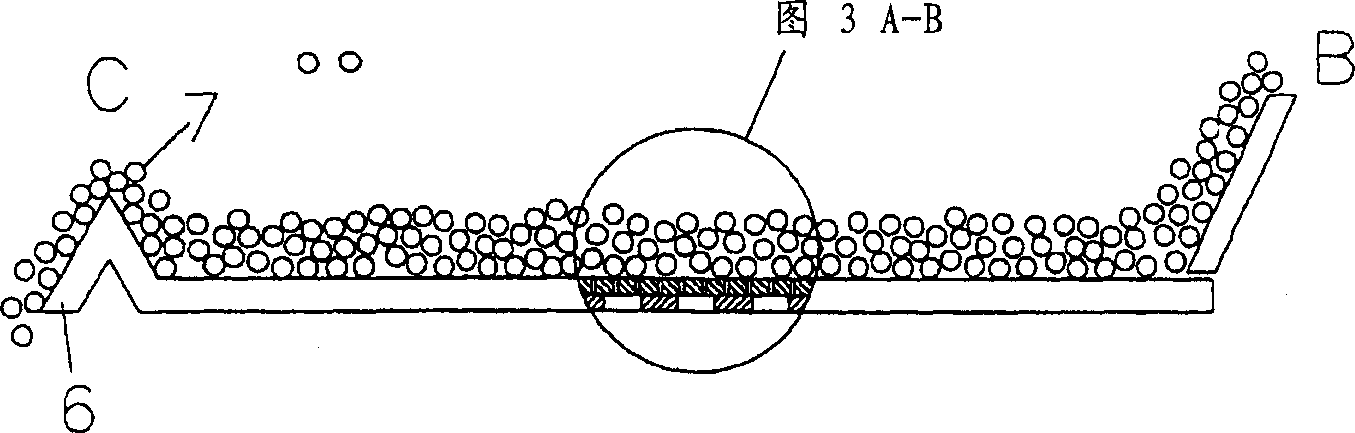

[0030] Material 7, ie food to be cooled, eg crops, corn, cauliflower, crisps, broccoli, etc., is brought into the device in a first position B, see Figs. 2A, 2B, 2C. The material is conveyed above the trough bottom 5 to a second location C where it leaves the trough bottom on a side wall / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com