Web rewinder with chop-off and transfer assembly

A technology of cutting device and web, applied in transportation and packaging, winding strips, sending objects, etc., can solve problems such as equipment failure, wrinkled web, etc., and achieve the effect of improving product quality and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following terms used here have the following meanings:

[0032] The "machine direction", denoted MD, is the direction parallel to the direction of paper movement within the paper processing equipment.

[0033] The "cross machine direction", denoted CD, is the direction perpendicular to the machine direction.

[0034] A "nip" is a loading surface that connects the centers of two parallel axes.

[0035] A "core winding cycle" is the time required to complete the rewinding of a predetermined length of paper onto a single core to produce a consumer product roll.

[0036] A "log" is a roll of paper wound on a core that has completed a core winding cycle.

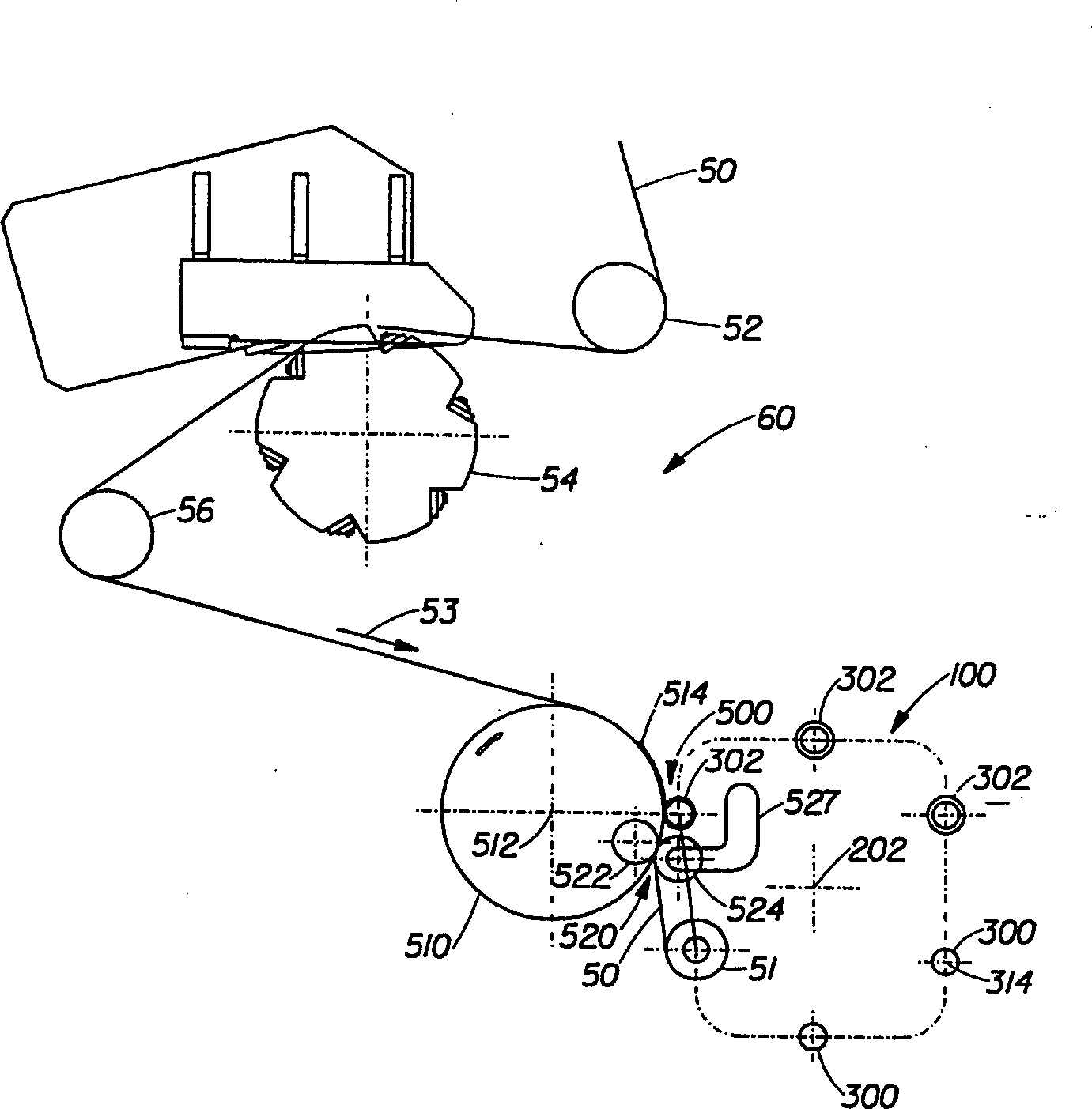

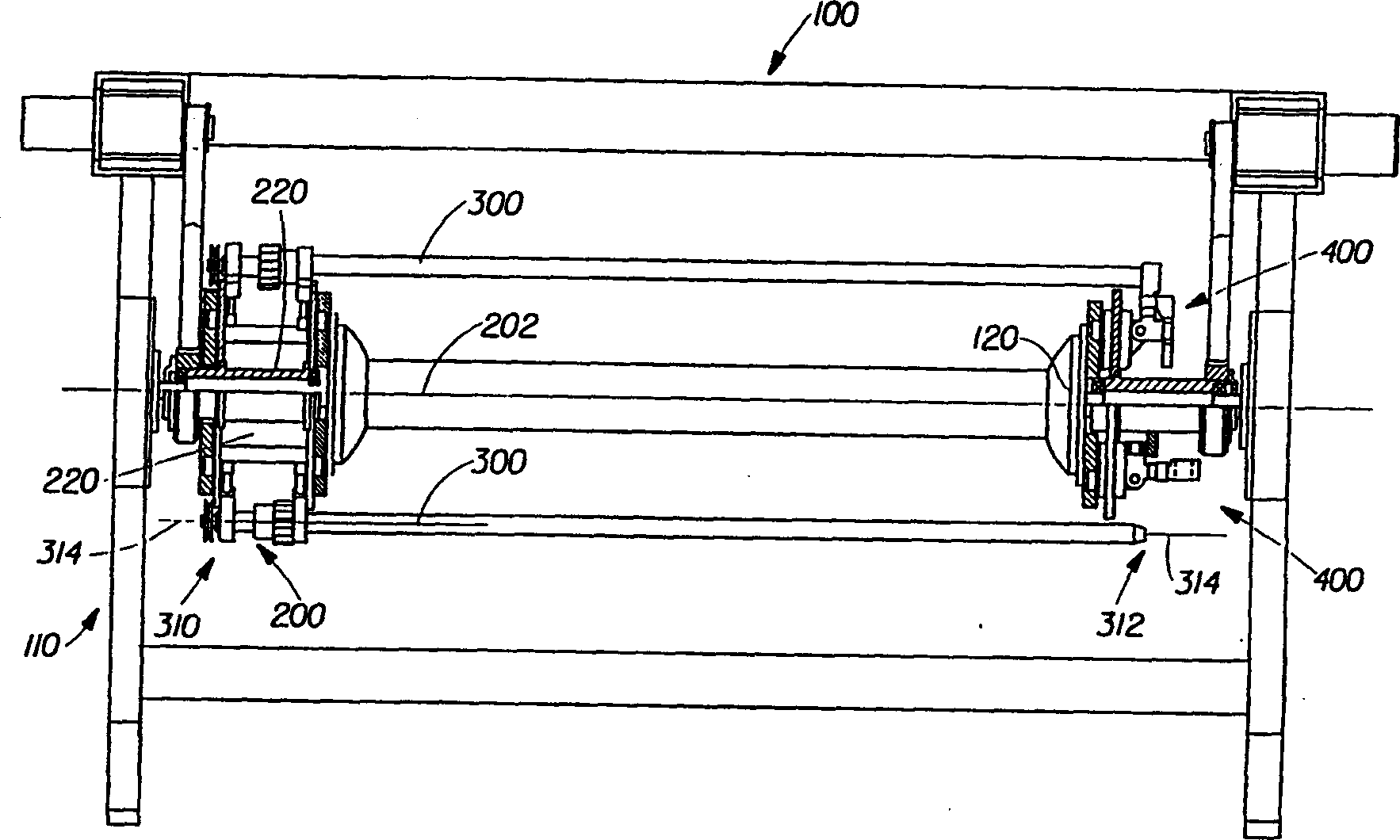

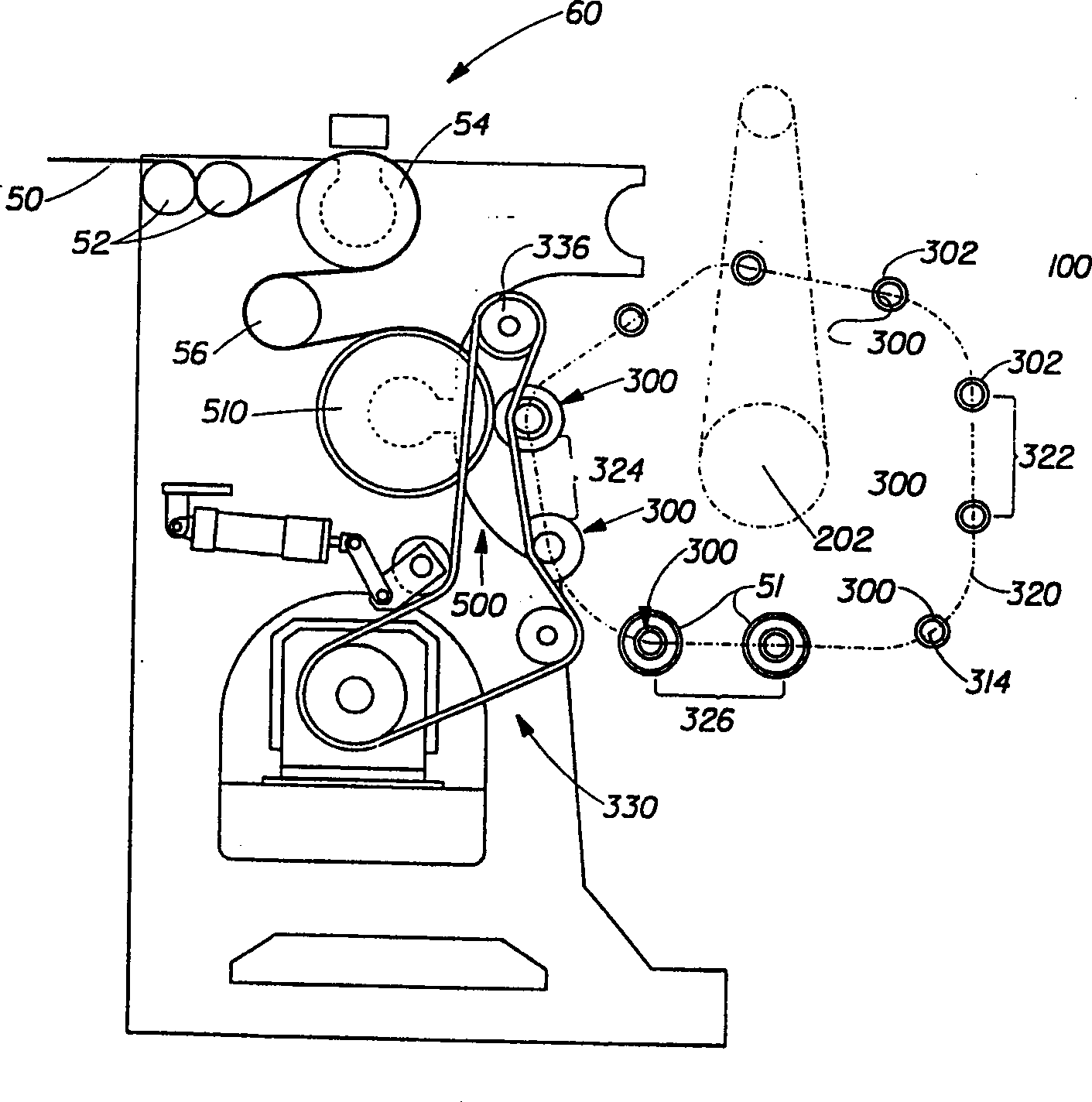

[0037] to attach figure 1 By way of example, it is a web rewind device 60 that rewinds a web 50 from a parent roll (not shown) onto a core layer 302 supported on a mandrel 300 of a rotary turret winder 100 . During web rewinding, web 50 travels in machine direction path 53 into perforation roll 54 which travels in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com