Drawer-type row-state thermo-sensitive primter

A technology for thermal printers and drawers, which is applied in printing devices, printing, thin material processing, etc., can solve problems such as thermal head exposure, and achieve the effect of improving the direction of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, in which

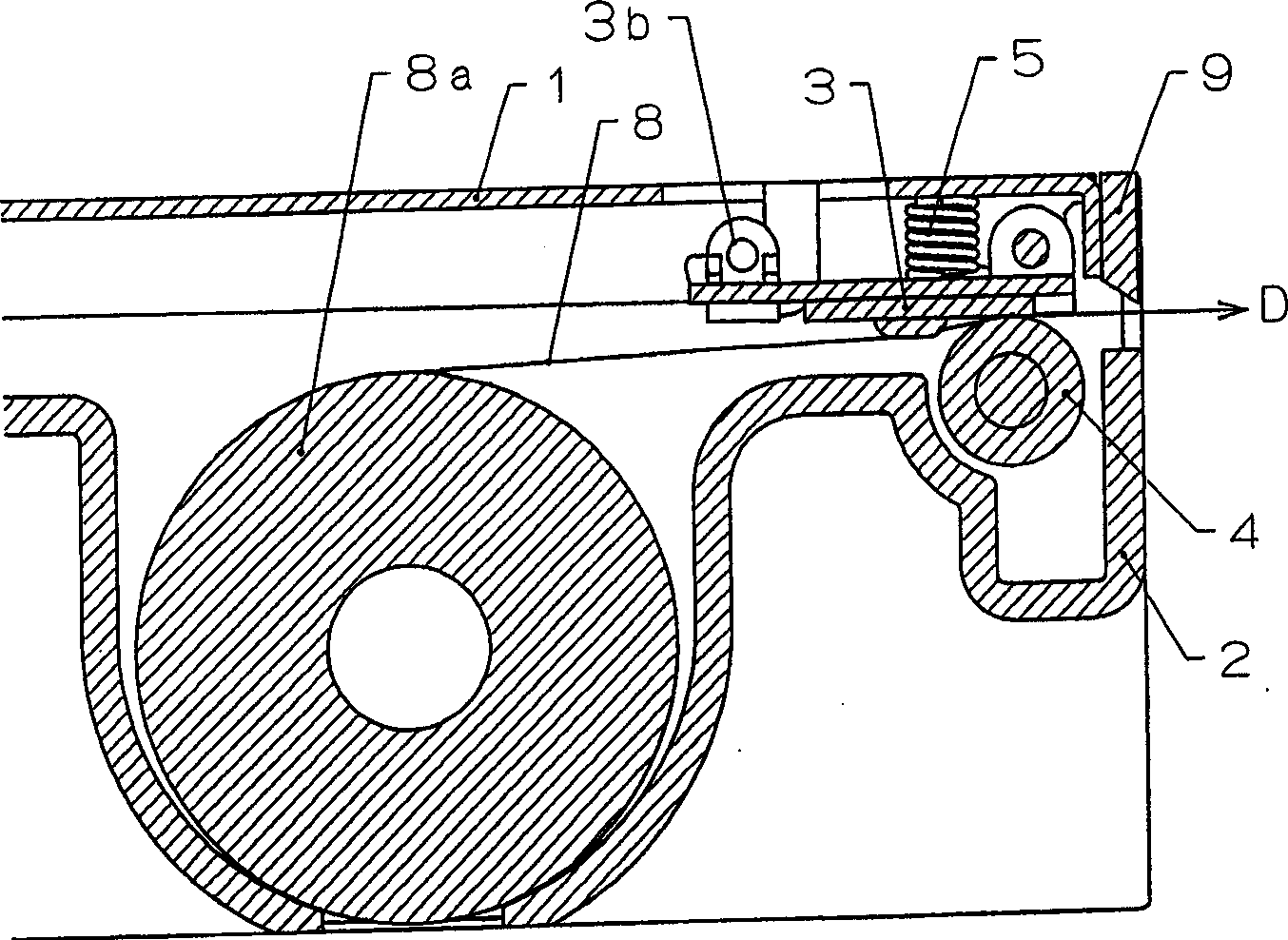

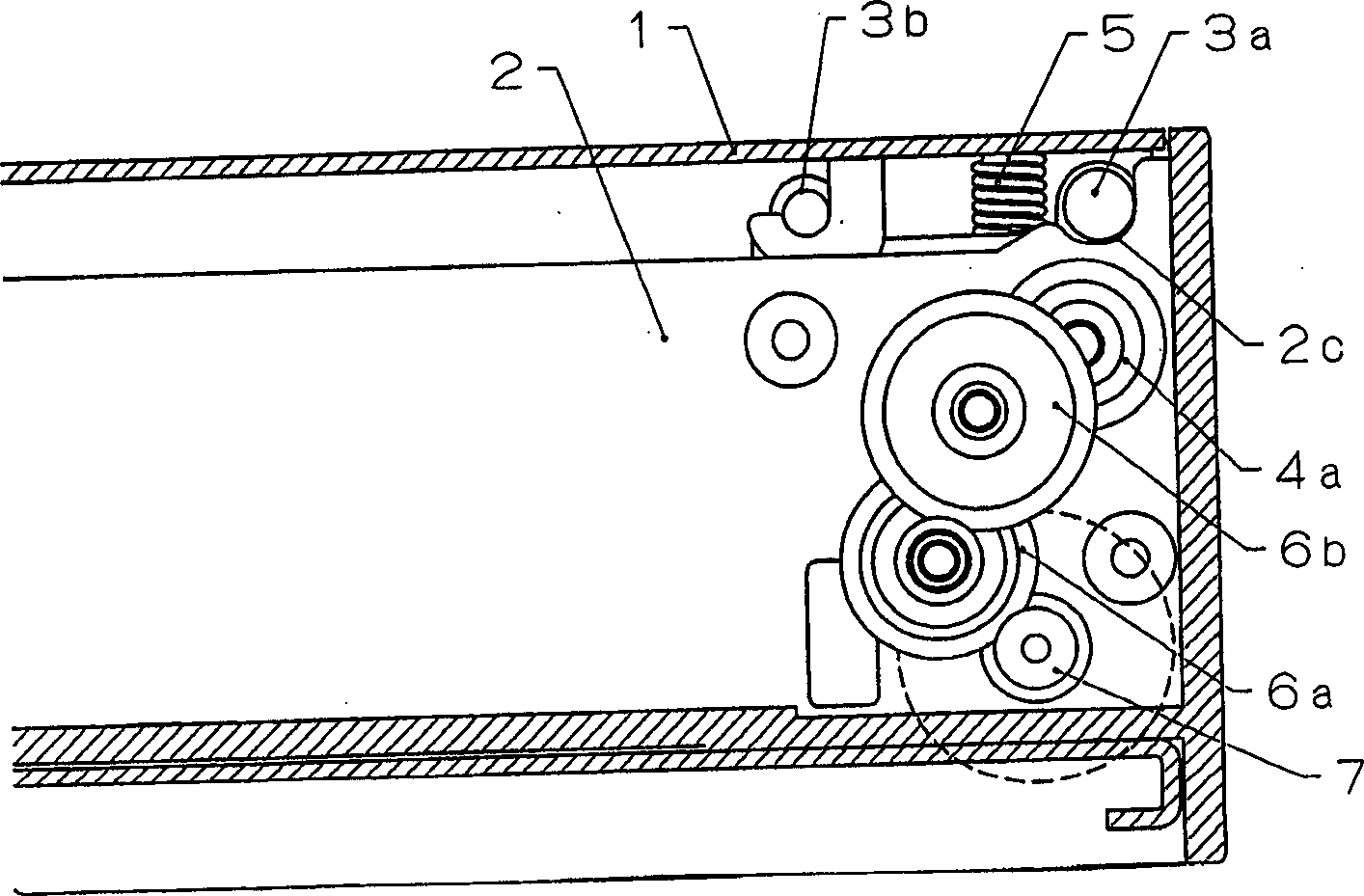

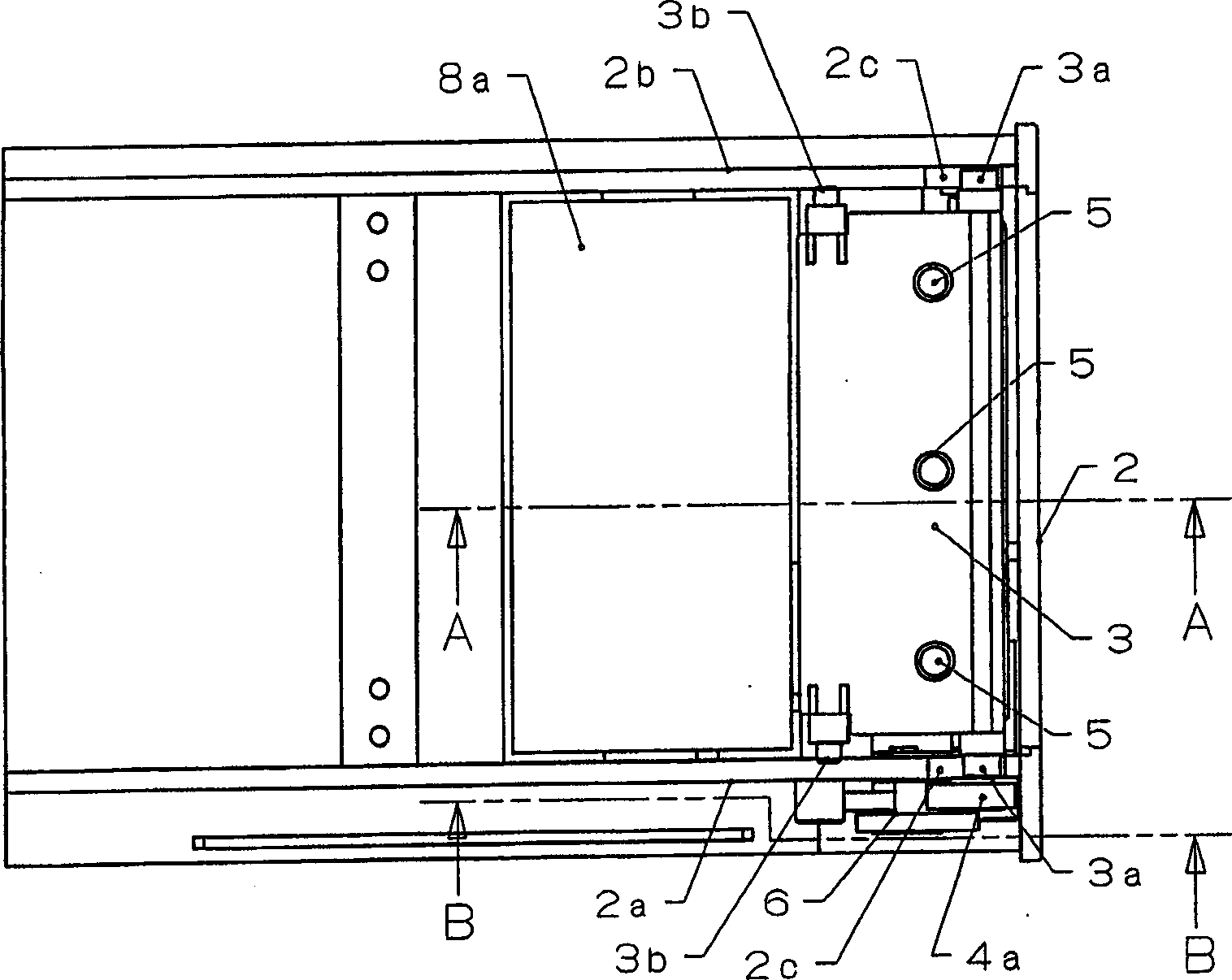

[0016] Figure 1 shows an illustrative side view illustrating an embodiment of the present invention; Figure 1A for the edge figure 2 a cross-sectional side view of line A-A shown; and Figure 1B for the edge figure 2 Cutaway side view of line B-B shown.

[0017] figure 2 To show a partial perspective top view of the entire device.

[0018] Figures 3 and 4 depict the operation of the various components when opening and closing the second frame 2; Figure 3A and 4A for the edge figure 2 a cross-sectional side view of line A-A shown; and Figure 3B and 4B for the edge figure 2 Cutaway side view of line B-B shown.

[0019] Figure 5 A perspective external view to depict the overall shape of a thermal printer according to the present invention.

[0020] FIG. 6 is a schematic diagram of a conventional clamshell type printer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com