Electret capacitance microphone and making method

A condenser microphone, electret technology, applied in electret electrostatic transducer, electrostatic transducer microphone, electrostatic sensor and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

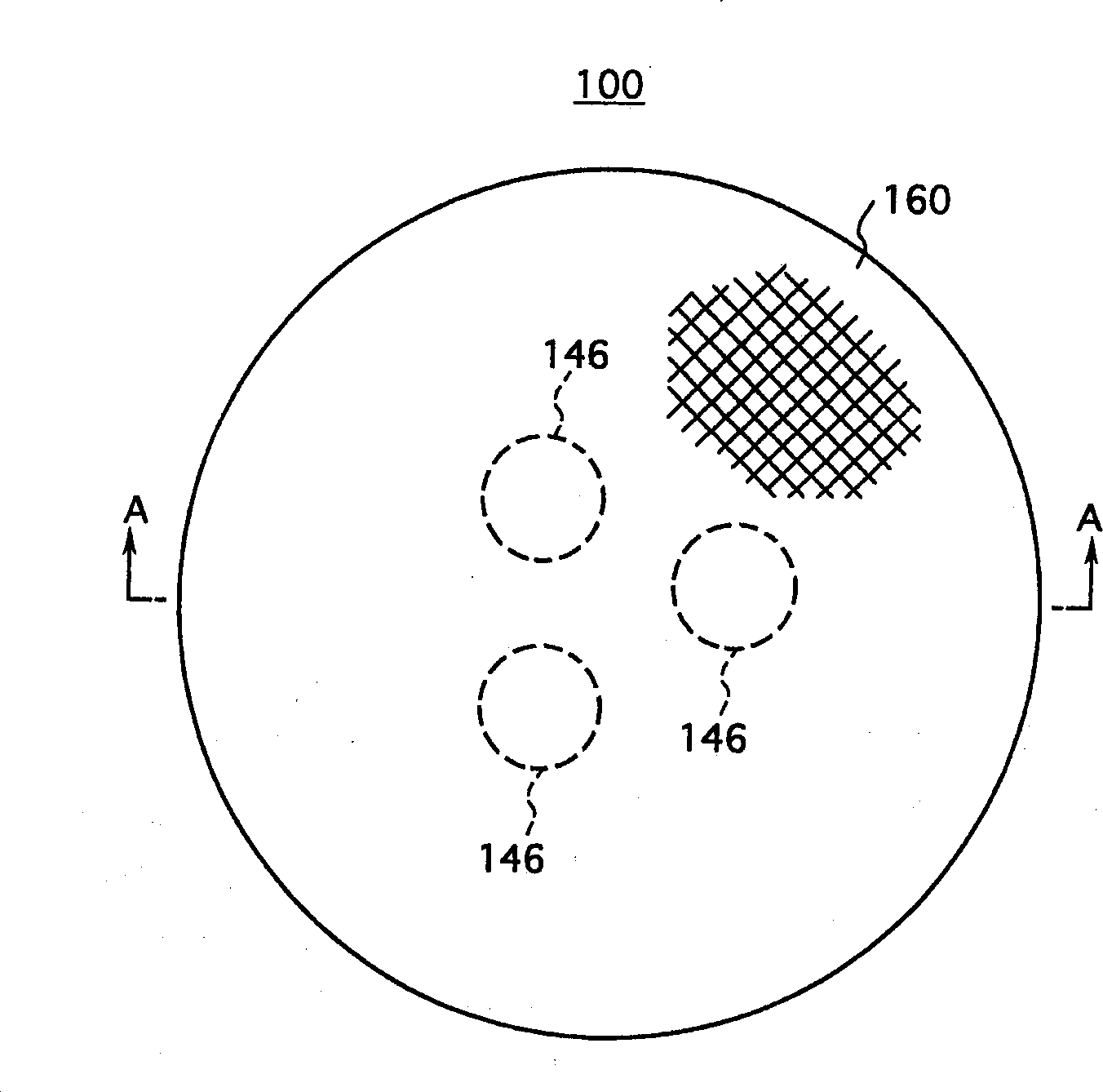

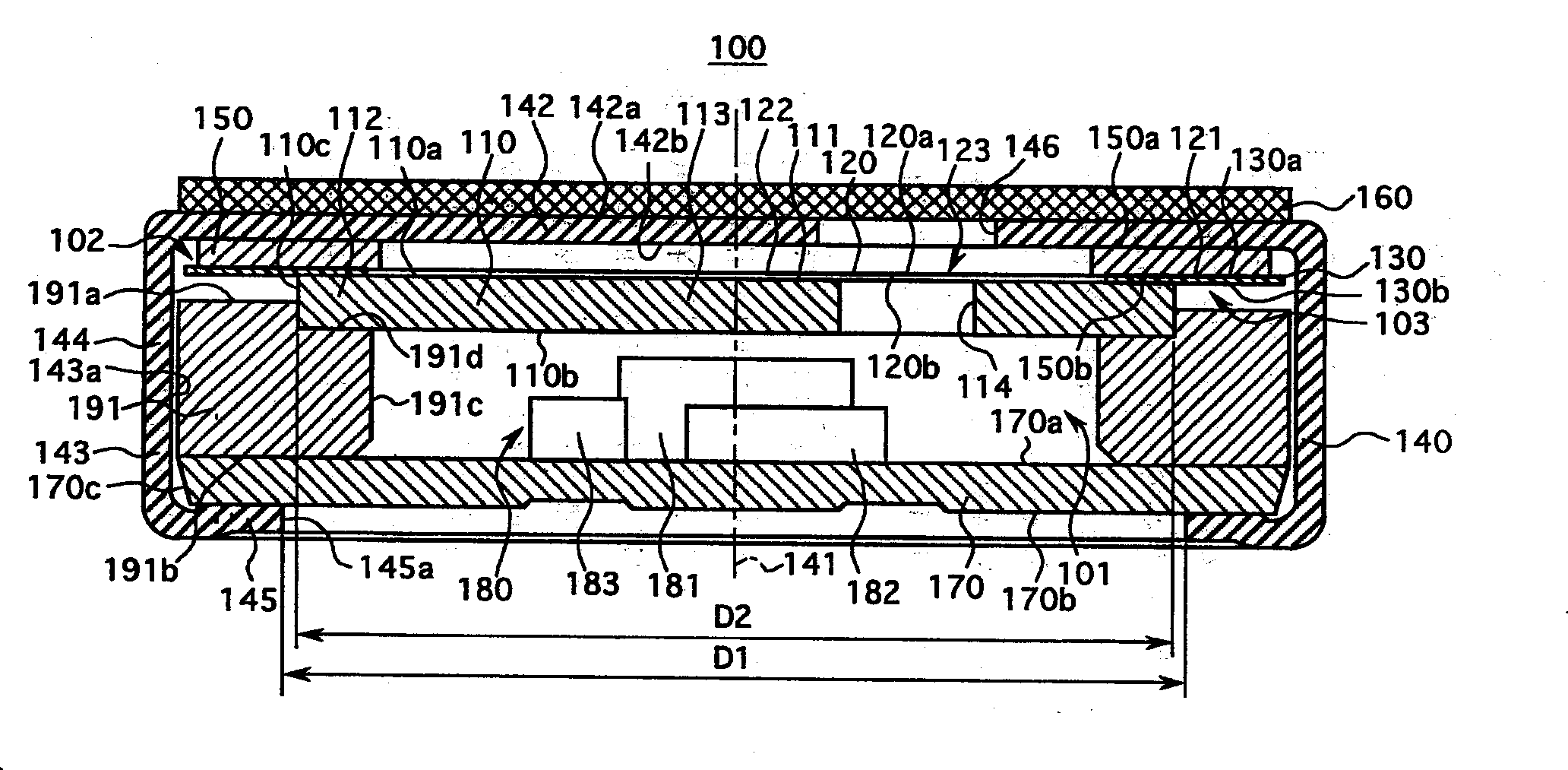

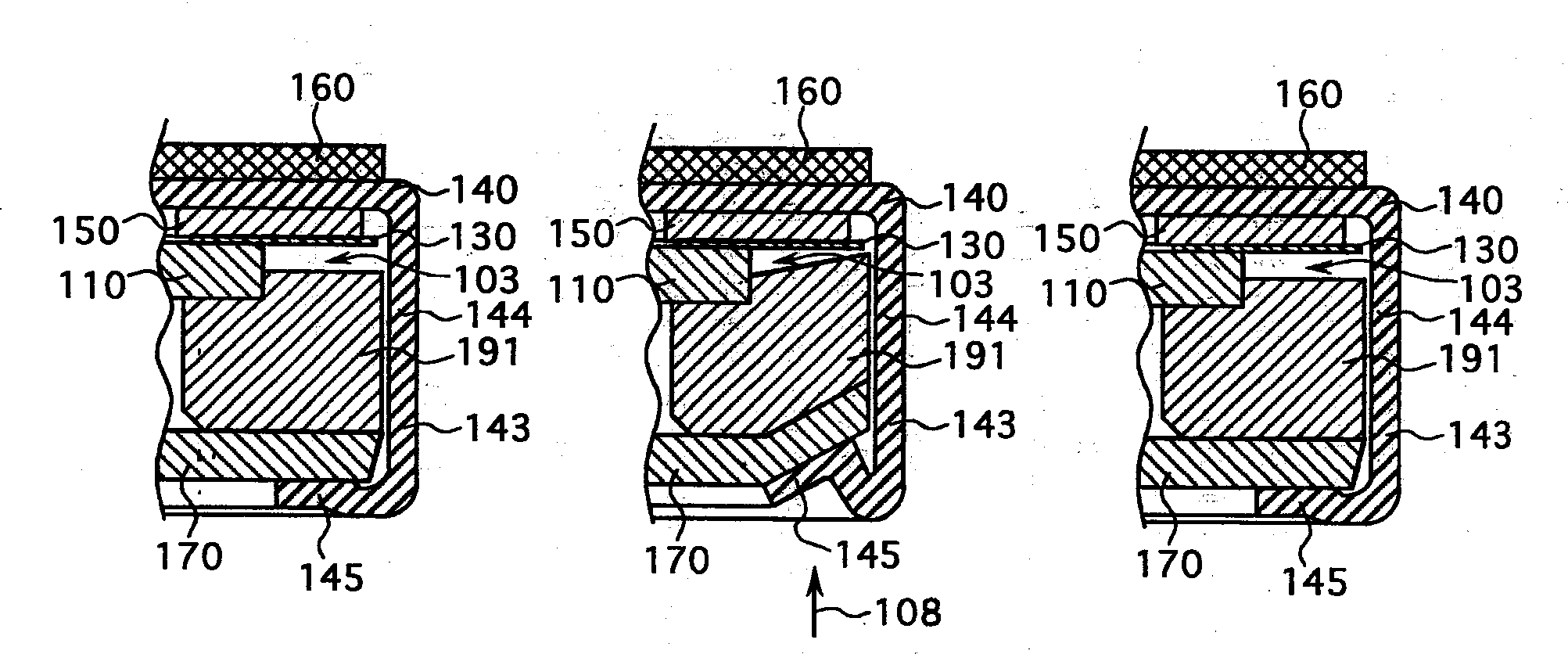

[0047] A first preferred embodiment of the electret condenser microphone according to the present invention will now be described in detail with reference to the accompanying drawings.

[0048] Referring now to the accompanying drawings, especially figure 1 Through 3, the first preferred embodiment of the electret condenser microphone according to the present invention is shown. The electret condenser microphone 100 is designed to receive sound waves for conversion into sound signals representing the sound waves. The electret condenser microphone 100 includes a cylindrical housing part 140 having a central axis 141 . The housing part 140 includes: a circular sound inlet part 142 having first and second circular surfaces 142a and 142b; and a cylindrical side part 143 integrally formed with the sound inlet part 142 of the housing part 140 and having a cylindrical shape. The inner surface 143a is connected to the second surface 142b of the sound inlet portion 142 of the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com