Polymer processing additive containing a multimodalfluoropolymer and melt processable thermoplastic polymer composition employing the same

A processing aid, melt processing technology, applied in the field of thermoplastic polymer composition, thermoplastic polymer melt processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0062] Preparation of multimodal partially crystalline fluoropolymers and comparison with unimodal partially crystalline fluoropolymers as processing aids to eliminate melt fracture in blown film extrusion. Four separate tests were performed. The table below documents the polymer processing aids, experimental conditions and test results.

[0063] Fluoroplastic

Material

Rated monomer composition (weight%)

TFE HFP VDF Ethylene Propylene

peak melting

body temperature

Melt Flow Index (1)

(MFI)

(g / 10min)

THVB

60

18

22

-

-

165

10

THVA

60

18

22

-

-

165

130

THVAA

60

18

22

-

-

165

>500

HTEB

62

24

-

14

-

160

10

HTEA

62

24

-

14

-

160

90

...

Embodiment 11

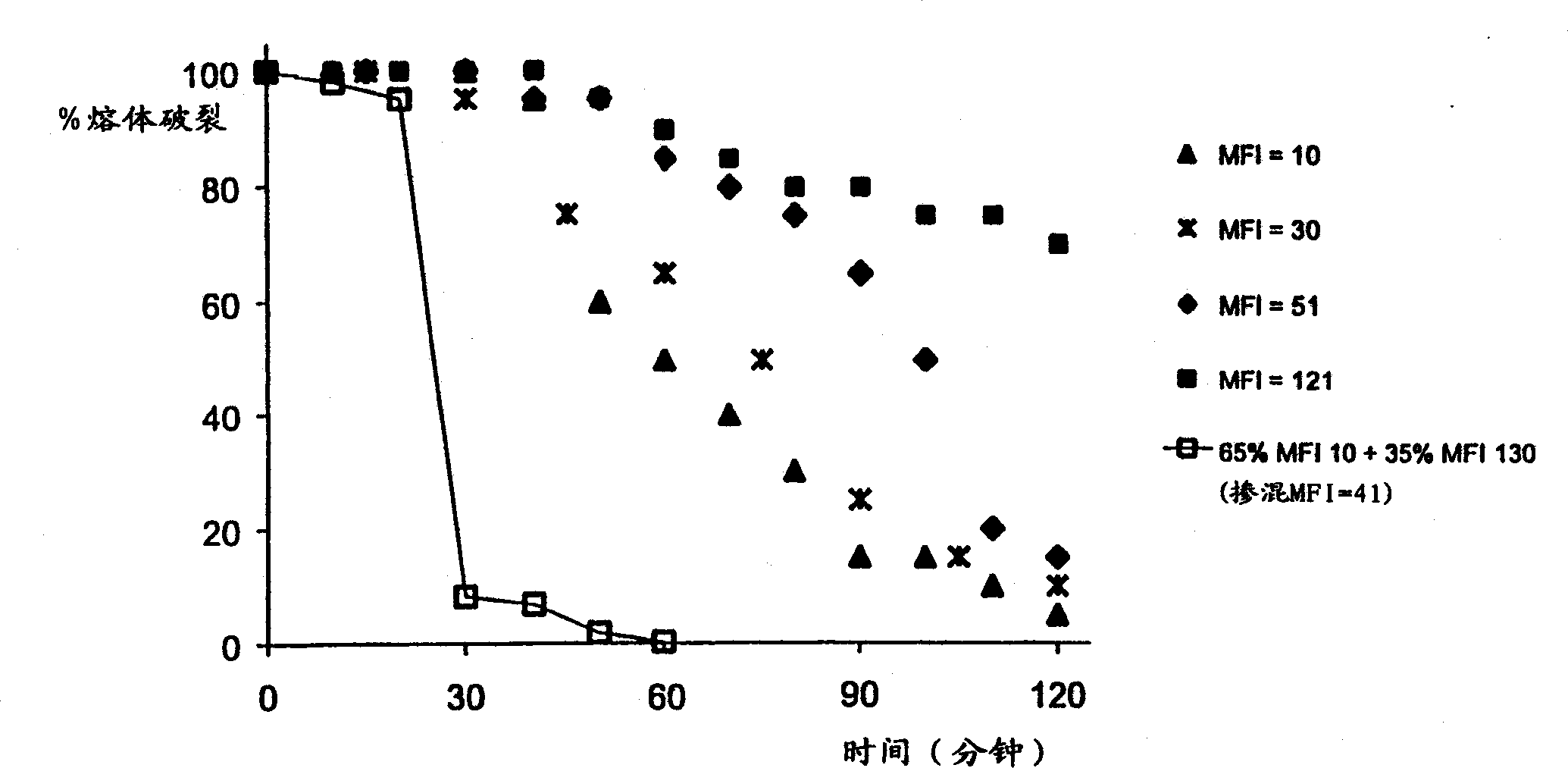

[0083] Blown films were prepared as described in Run 3 of Examples 1-10. The effect of five different additive compositions on the melt processability of polyethylene was evaluated. The first additive composition is the multimodal composition of the present invention. It contains 35% by weight THVA and 65% by weight THVB (MFI A : MFI B = 13:1). The blended MFI of the multimodal fluoropolymer additive composition was 41. Other additive compositions include unimodal fluoroplastic polymers nominally having the same monomer composition as THVA. The MFI values of unimodal fluoroplastics are 121, 51, 30 and 10, respectively. The times to eliminate melt fracture for each additive composition are shown in Table 1.

[0084] As can be seen from Table 1, only the multimodal fluoropolymer-based additive composition was able to achieve melt fracture elimination after only 60 minutes of extrusion. The unimodal fluoropolymer did not eliminate melt fracture even after 120 minutes of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com