Illumination system and method for producing light-beam with required form

A lighting system and light beam technology, which is applied in the field of lighting systems, can solve problems such as manufacturing tolerances of fastening devices, limiting system effectiveness and light energy, etc., and achieve the effect of reduced structure size and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

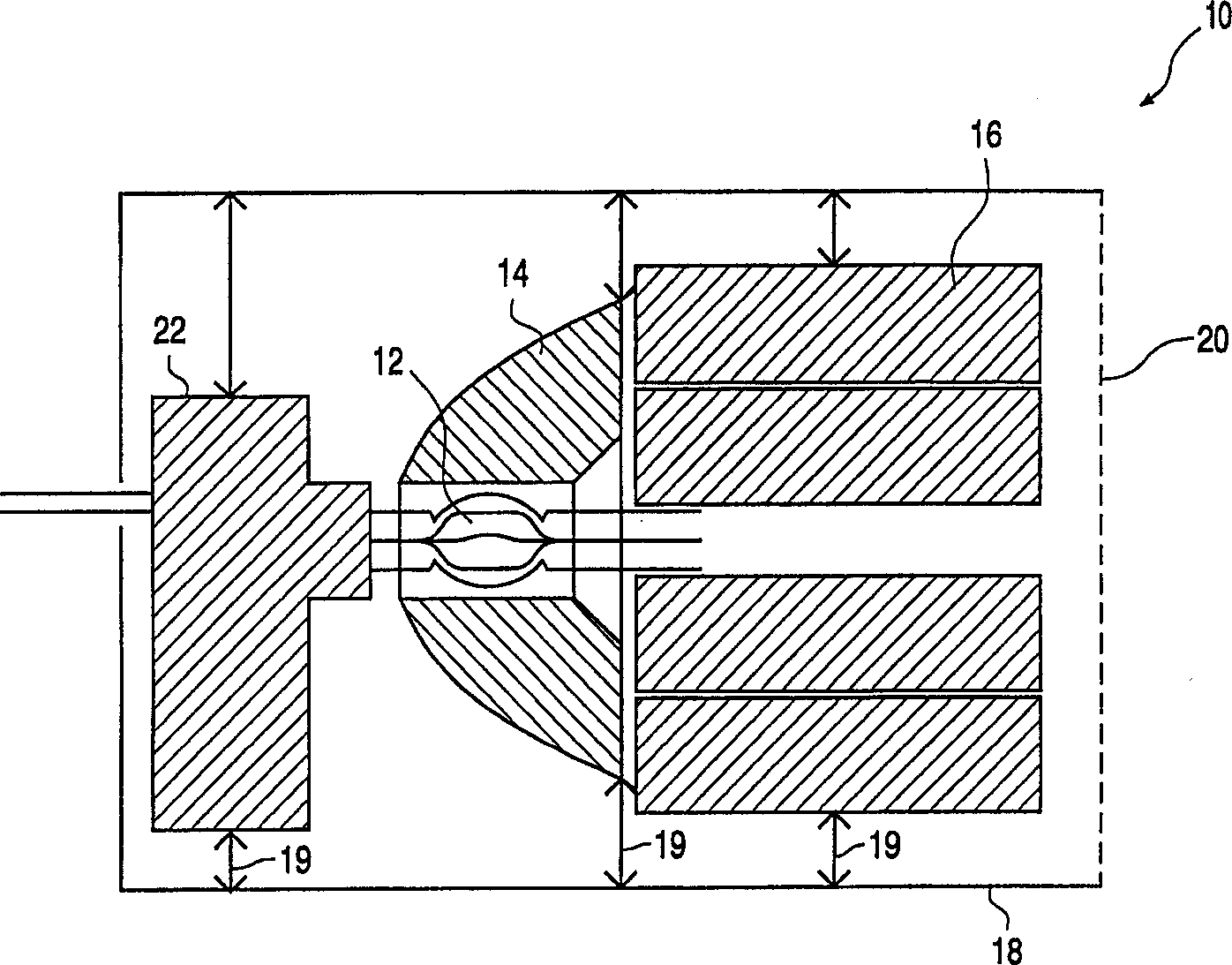

[0029] figure 1 A lighting system is shown, indicated by 10 as a whole. Its main components are a light source 12 in the form of a discharge lamp, a collector 14 and a number of separators 16, which together form a light-collecting separator, arranged with a light transmission Inside the housing 18 of the front part 20. The components for controlling the discharge lamp 12 and a ballast 20 are held in the housing 18 in a suitable and adjustable manner by a corresponding known holding device 24.

[0030] The collector 14 and the separator 16 are solid elements, which means that compared with the usual system, the light guiding and the formation of the beam occur in the transparent material, and the light from the light source to the lighting system is basically not in Moving in the air, but moving in a fixed medium.

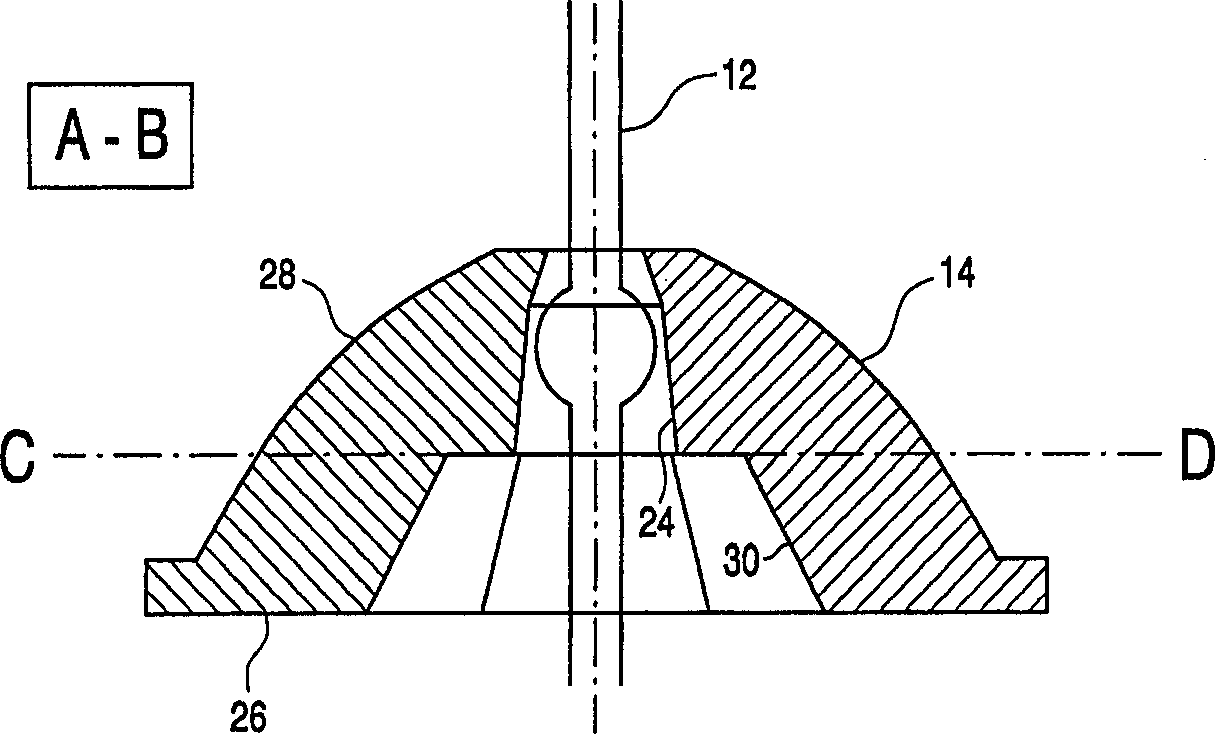

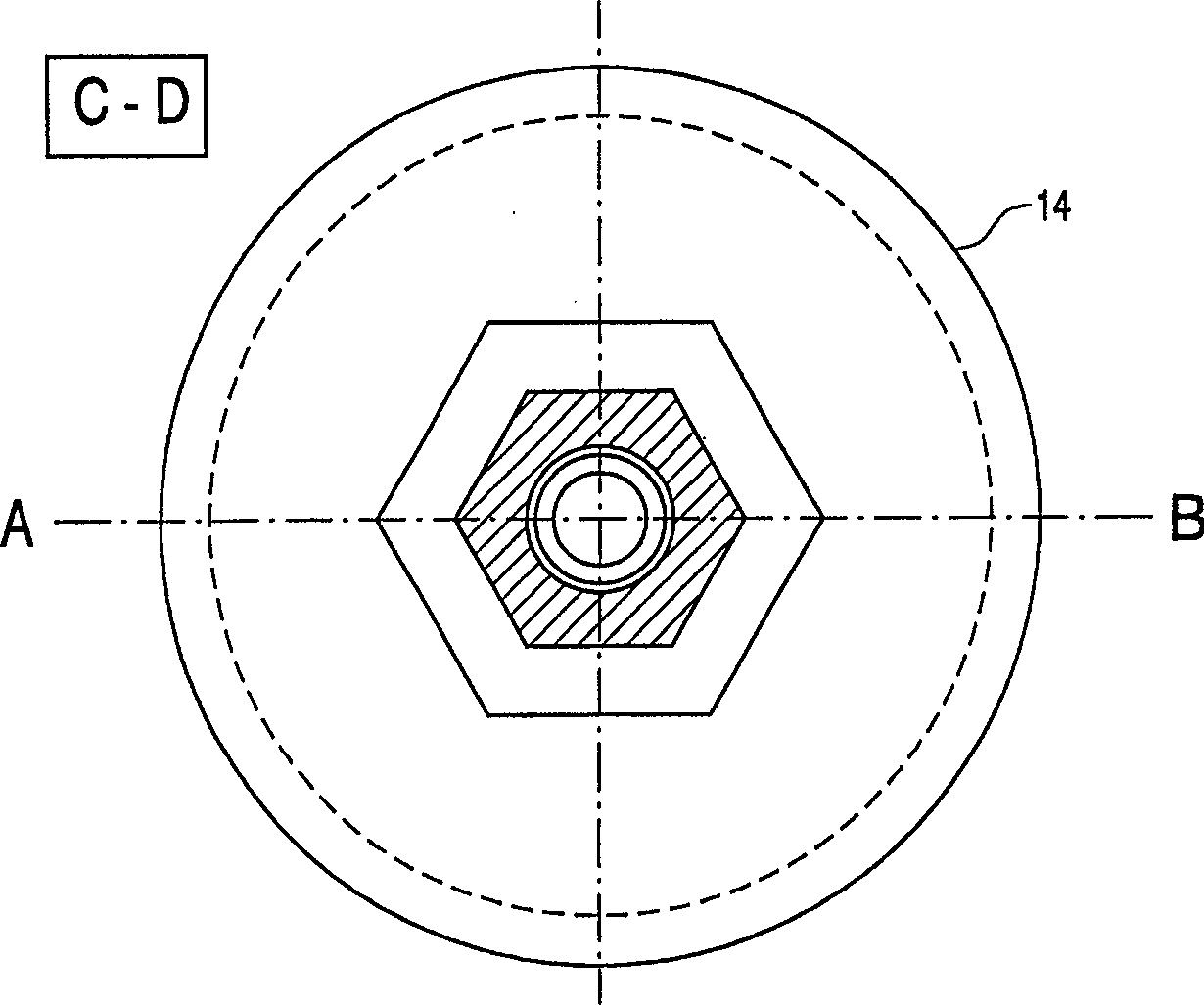

[0031] figure 2 with image 3 Two front views of the collector 14 are shown. One of the main characteristics of the present invention is clearly observed, which co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com