Electromagnetic drive

An electromagnetically driven and driven technology, applied to electromagnets, electromagnets with armatures, circuits, etc., can solve the problem that the old solenoid device 100 cannot fully adapt to the miniaturization of lens barrels or cameras

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below using the drawings.

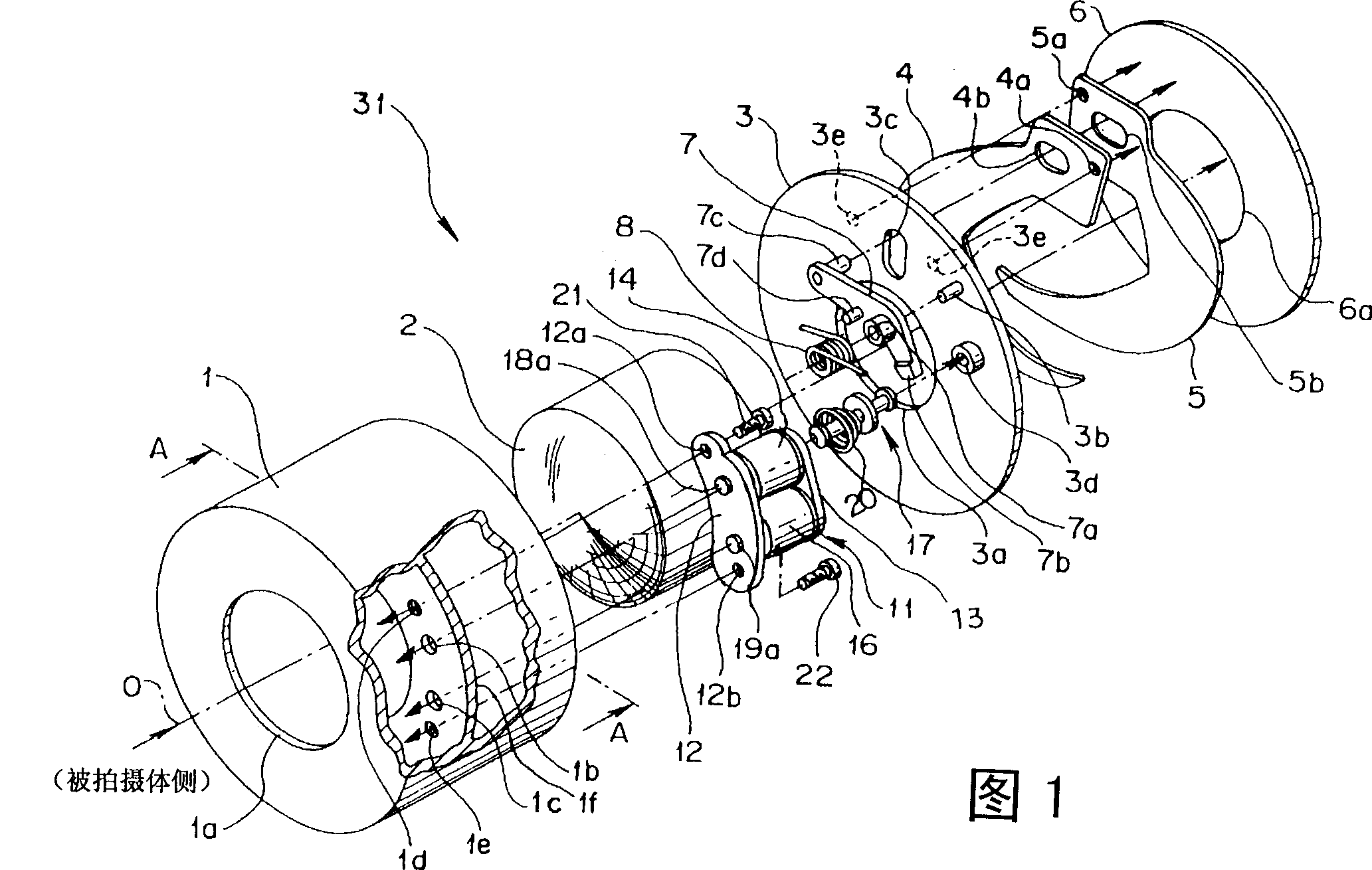

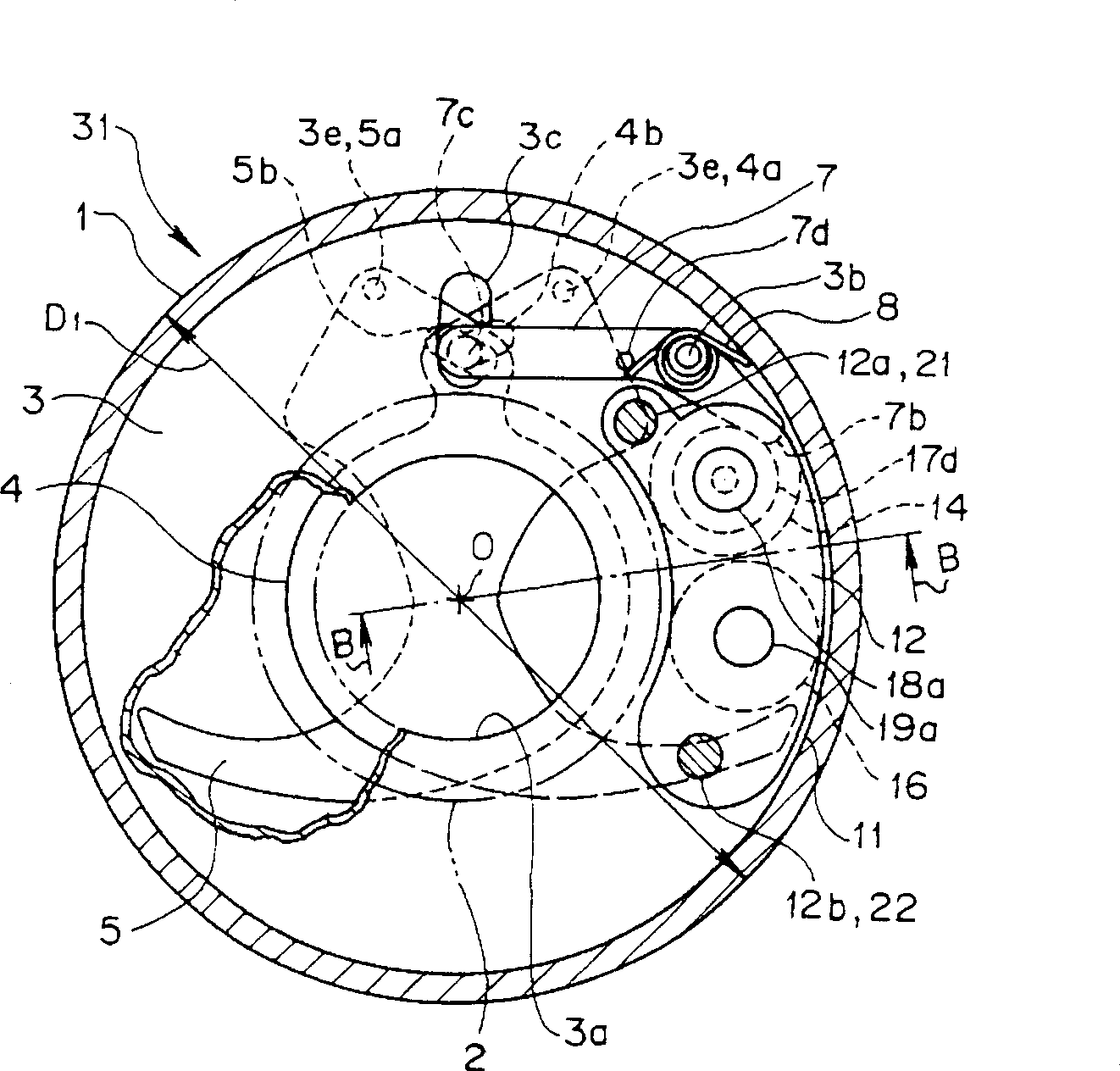

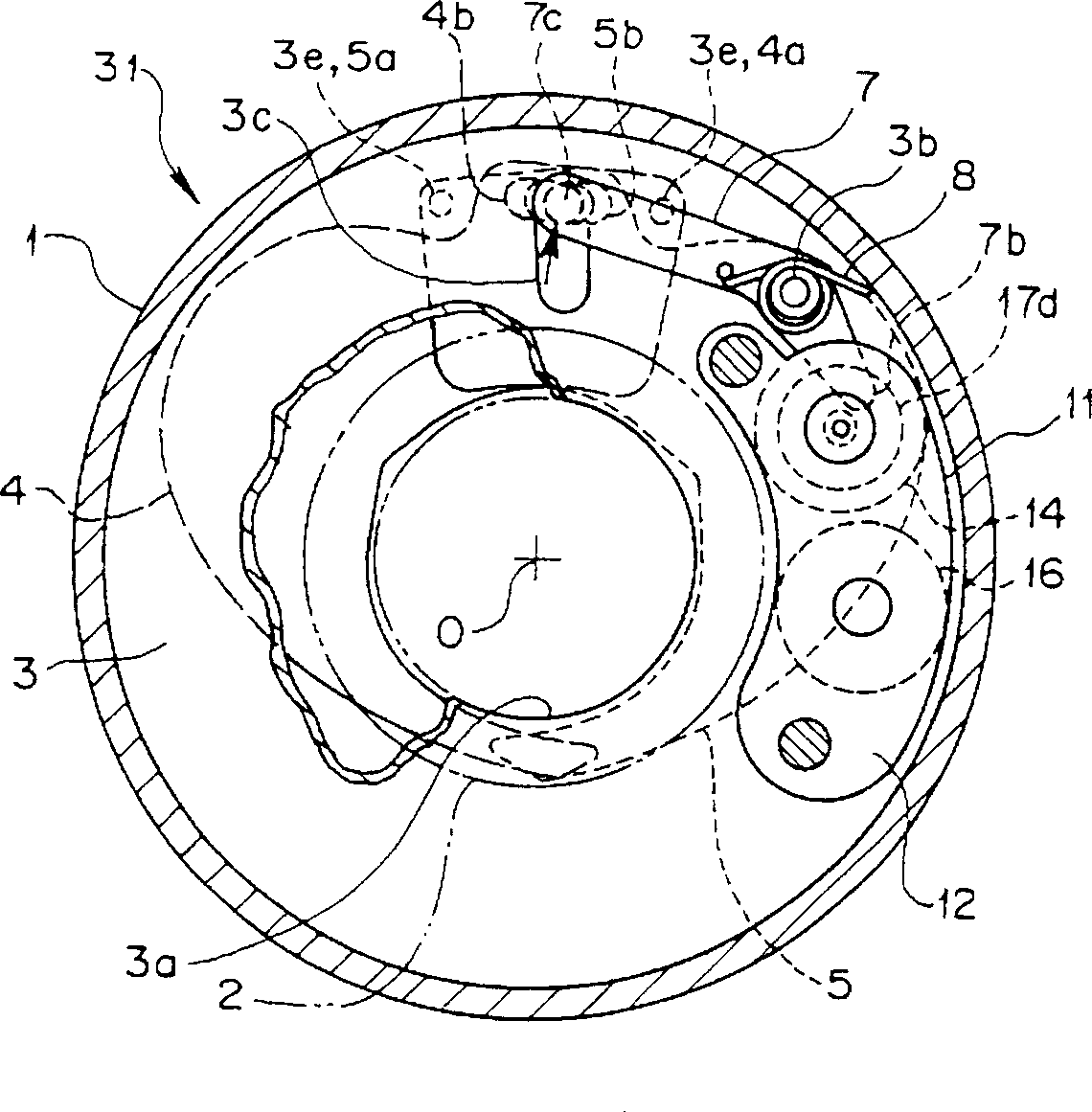

[0034] Fig. 1 is an exploded perspective view of a lens barrel according to a first embodiment of the present invention, in which an electromagnetic drive device for exposure control is assembled. figure 2 , 3 It is the A-A sectional view of Fig. 1, figure 2 Indicates that the shutter blades are closed, image 3 Indicates the shutter blade open state. Figure 4 Yes figure 2 The B-B cross-sectional view. Fig. 5 is a view of the above-mentioned electromagnetic drive device viewed from the protruding surface side of the plunger. Fig. 6 is a sectional view taken along line C-C of Fig. 5, which shows the protruding state of the plunger core. Figure 7 It is the F direction view of Fig. 6. Figure 8 It is an enlarged view of part D in FIG. 6 . Figure 9 It is an enlarged view of part E of FIG. 6 . In addition, in the following description, the turning direction is indicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com