High-frequency filter

A high-frequency filter and frequency characteristic technology, applied in waveguide-type devices, impedance networks, electrical components, etc., can solve the problems of reducing the size of electrodes, limiting the miniaturization of filters, etc., to prevent damage and damage, and increase the adjustment range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

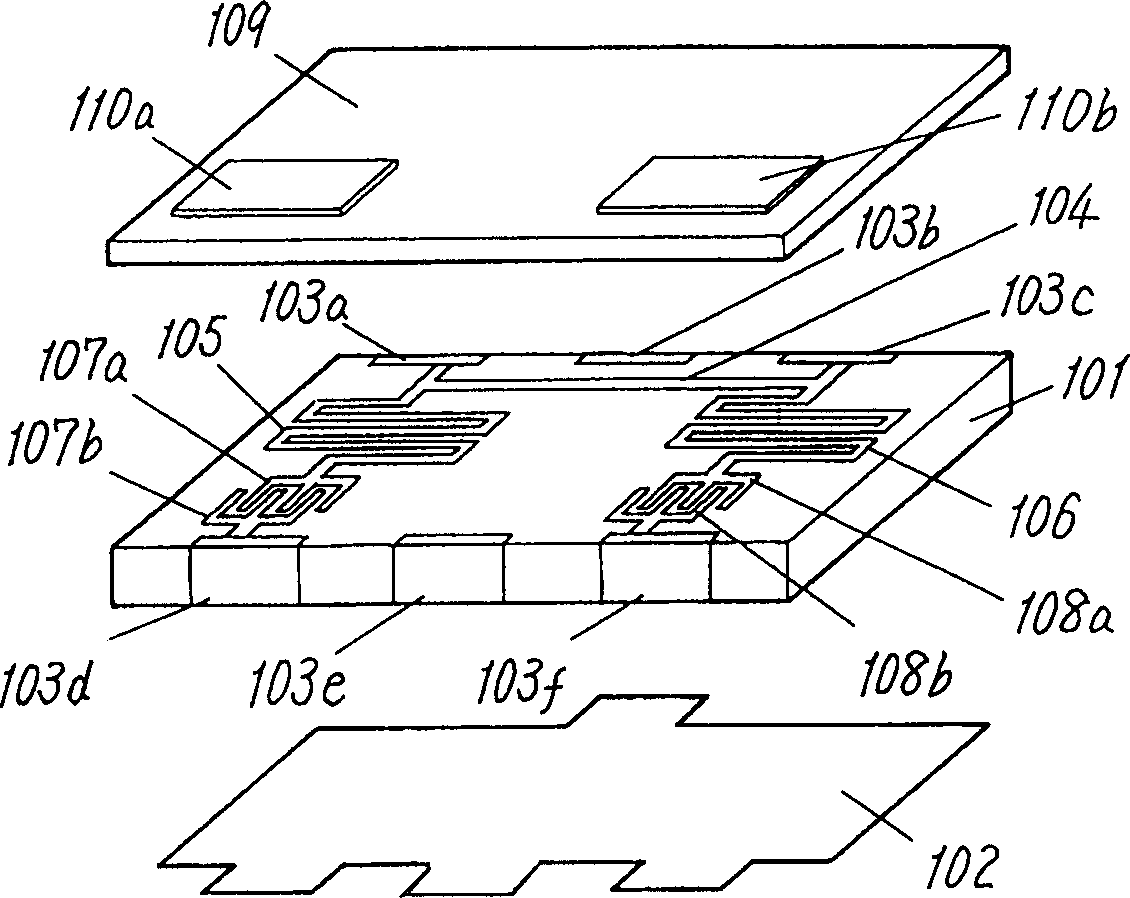

Embodiment 1

[0038] figure 1 It is a diagram showing the configuration of the high-frequency filter according to Embodiment 1 of the present invention. In the high-frequency filter of this embodiment, the ground electrode 102 is formed on the lower surface of the dielectric 101, and the end surface electrodes 103a, 103b, 103c, 103d, 103e, and 103f are formed from the side surfaces of the dielectric 101 and partially curved upward. Also, on the upper surface of the dielectric 101, the first transmission line electrode 104, the second transmission line electrode 105, the third transmission line electrode 106, the first comb-shaped electrodes 107a / 107b, and the second comb-shaped electrodes 108a / 108b are formed. Furthermore, a dielectric layer 109 is laminated on the upper side of these electrodes, and adjustment dielectric layers 110a and 110b are formed on the upper side to at least partially overlap the first comb-shaped electrodes 107a / 107b and the second comb-shaped electrodes 108a / 108b...

Embodiment 2

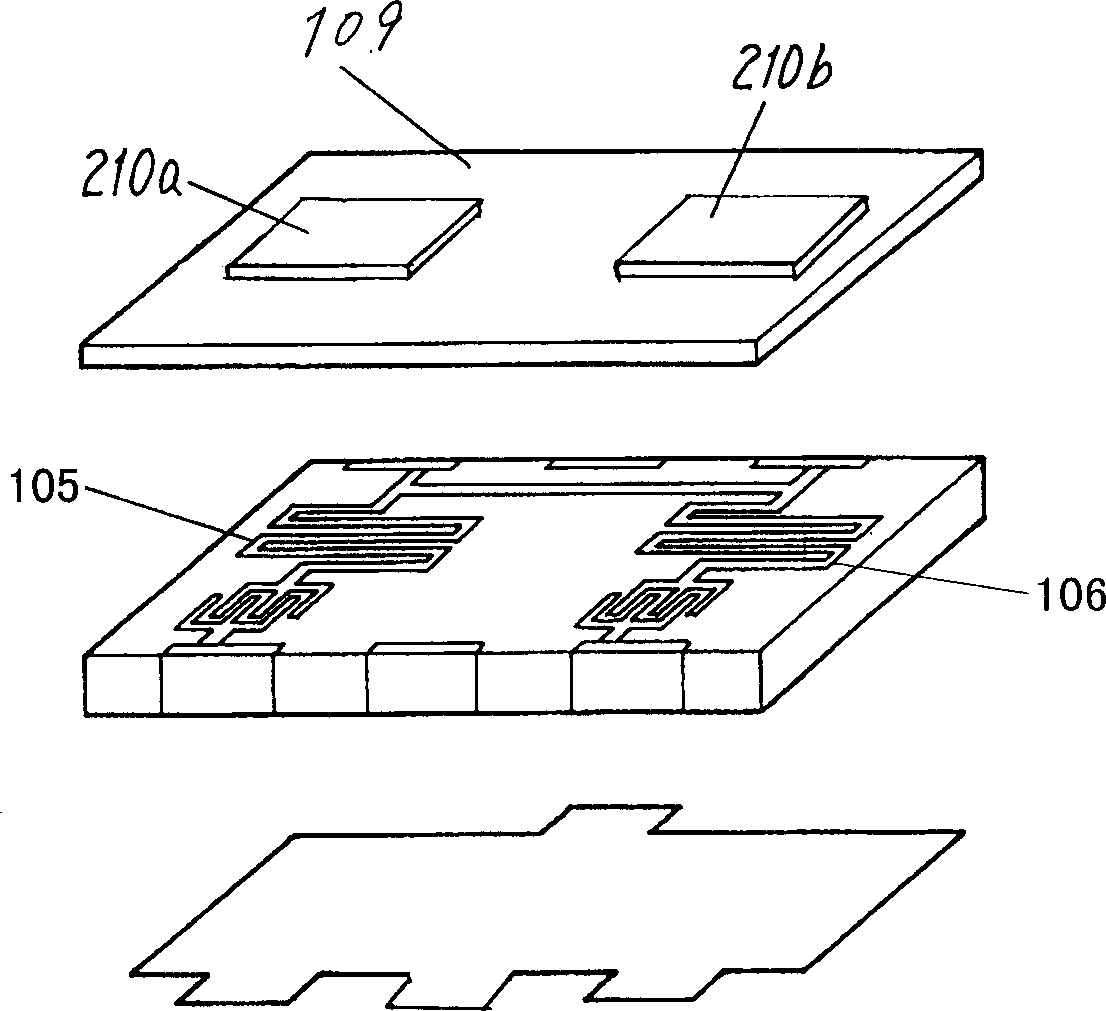

[0043] figure 2It is a diagram showing the configuration of a high-frequency filter according to Embodiment 2 of the present invention. The difference between the high-frequency filter of this embodiment and the first embodiment lies in the formation position of the dielectric layer for adjustment. In this embodiment, the adjustment dielectric layers 210a and 210b, such as figure 2 As shown, the dielectric layer 109 overlaps at least a portion of the transmission line electrodes 105 and 106 . In this way, by changing the effective permittivity of these transmission line electrodes and adjusting the inductance value of the inductor, the frequency characteristics of the high-frequency filter can be adjusted.

[0044] In addition, in the high-frequency filter of this embodiment, a magnetic medium layer for adjustment may be used instead of a dielectric layer for adjustment. In this way, the range of adjustable inductance values can be increased. In addition, in the high-f...

Embodiment 3

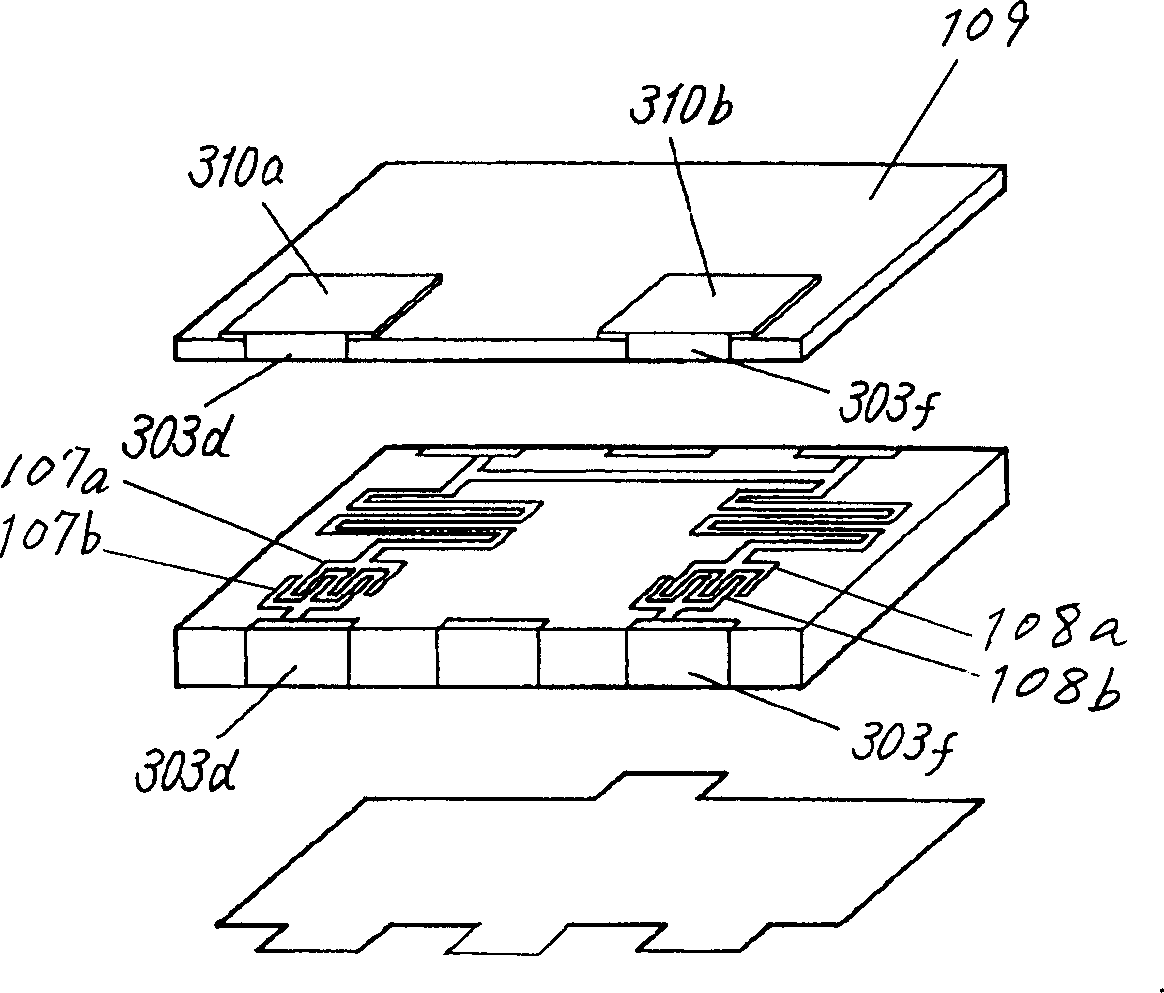

[0046] image 3 It is a diagram showing the configuration of a high-frequency filter according to Embodiment 3 of the present invention. The high frequency filter of this embodiment, such as image 3 As shown, the conductor layers 310a and 310b for adjustment are provided, instead of the dielectric layer for adjustment, and end surface electrodes 303d and 303f are used for grounding. The structure is the same as that of the first embodiment except that. exist image 3 Among them, the conductive layers 310a and 310b for adjustment are formed on the comb-shaped electrodes, since a capacitance proportional to the occupied area of the comb-shaped electrodes is added, so the range of adjustable capacitance can be enlarged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com