IGBT module

A branch circuit and magnetic ring technology, applied in the field of electronic components, can solve the problems of low system efficiency, large size, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

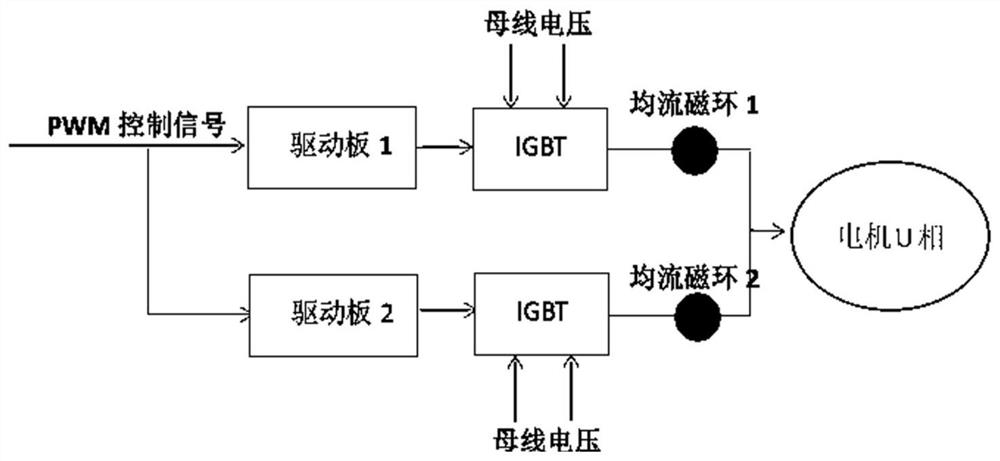

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0030] The present invention mainly adopts the method of current sharing inductance to improve the dynamic current sharing effect of the parallel IGBT, and the current sharing inductance adopts the method of sleeve magnetic ring design, this scheme realizes the soft switching of the IGBT parallel current sharing circuit, reduces the switching process Power loss, prevent IGBT overheating, and effectively protect IGBT devices and circuits.

[0031] like figure 1 As shown, it is the circuit diagram of the IGBT module of the present invention, the first branch is composed of the first IGBT driver board and the first IGBT device in series; the lower two branches are composed of the second IGBT driver board and the second IGBT device in series; the IGBT module of the present invention consists of The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com