Resilient member with deformed element and method of forming same

A technology of elastic components and parts, applied in the field of equipment containing elastic materials, can solve problems such as no pressure fit, abnormally large rotational resistance torque, violent impact, etc., and achieve the effect of small fit tolerance, low cost, and good bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Detailed description of preferred embodiments

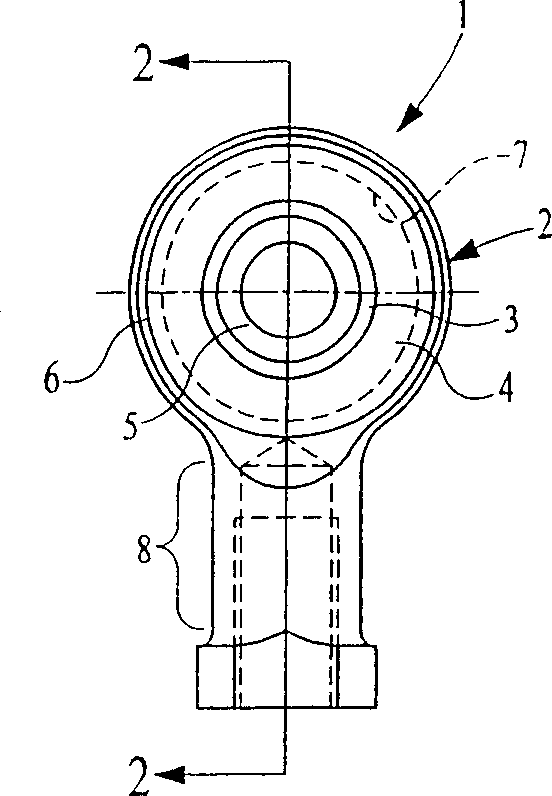

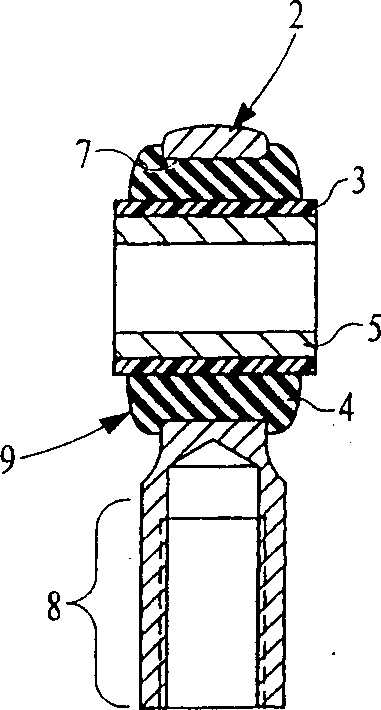

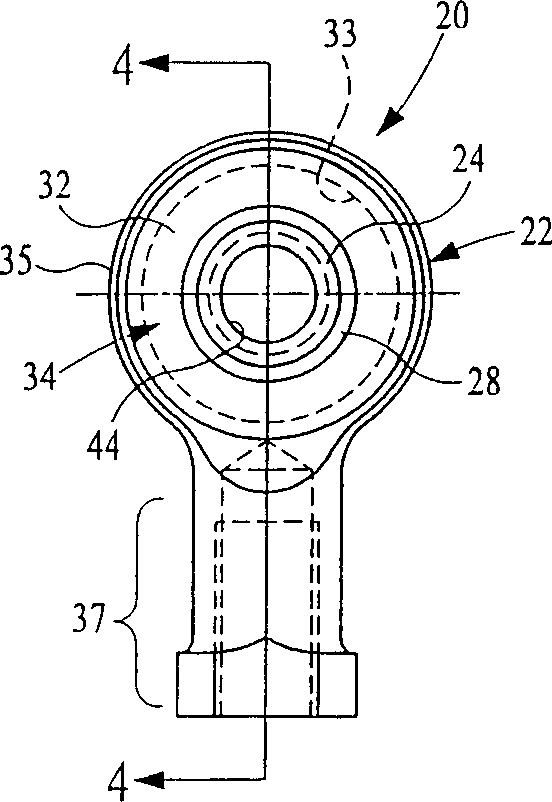

[0032] The first embodiment of the present invention Figure 3-4 Shown. The present invention is illustrated with an embodiment of an elastic rod end, but it can be seen from the following description that the present invention can be widely used in bearings, shock absorbers, brackets and shock absorbers. The invention can be used to permanently fix one part relative to another part when needed. Moreover, when a good bearing function is required, the present invention provides an effective and low-cost method of approximate line-line fit between parts.

[0033] According to the present invention, the elastic member 20 in the rod end structure includes a rigid first part 24, such as an inner sleeve, a deformable second part 28, such as a thermoplastic cylindrical sleeve as shown, and a Two-part elastic part 32, such as synthetic rubber or other rubber-like elastic material parts. The third part 22, such as the rigid rod end cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com