One-way overrunning clutch

A one-way overrunning and clutch technology, applied to one-way clutches, clutches, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

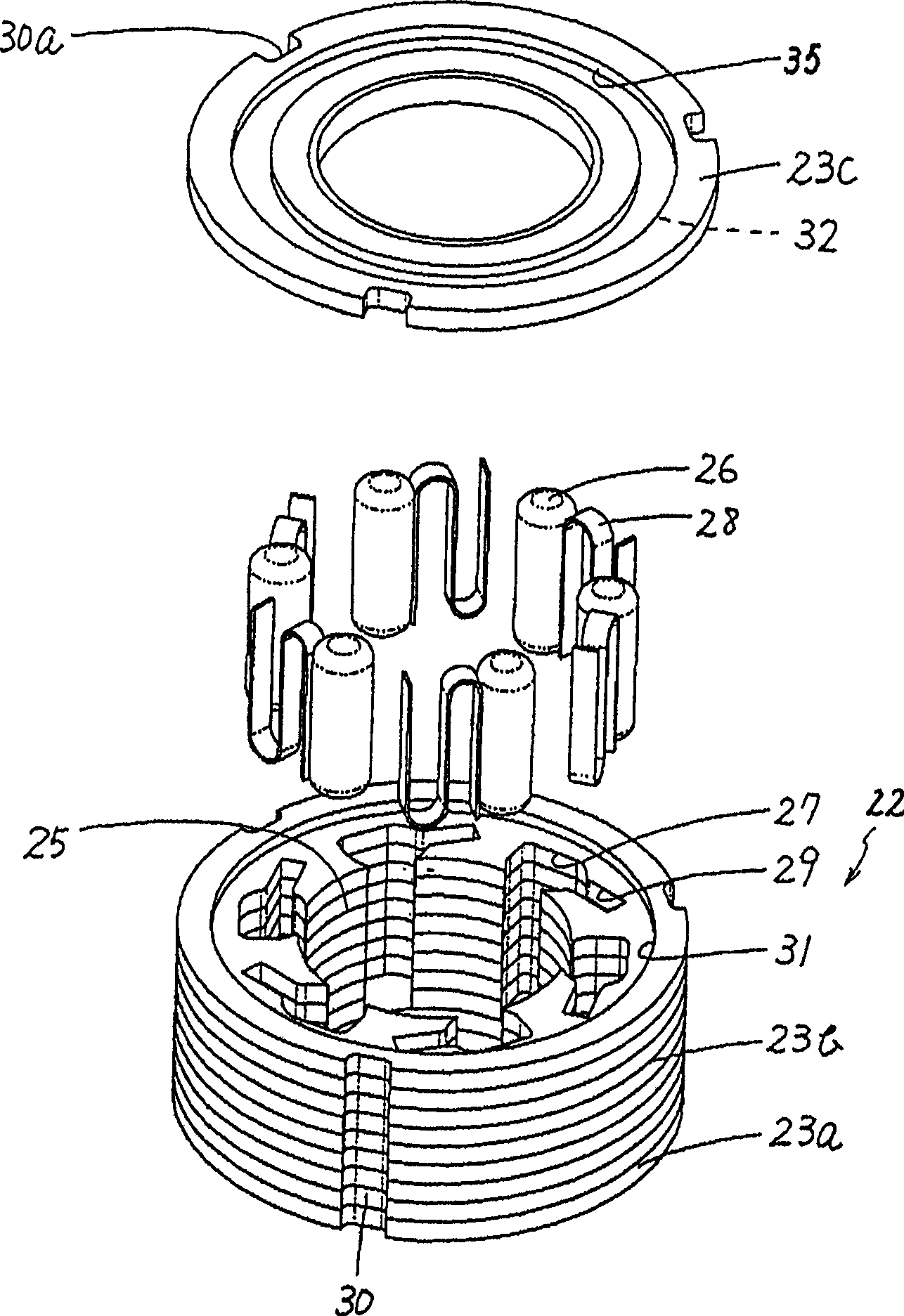

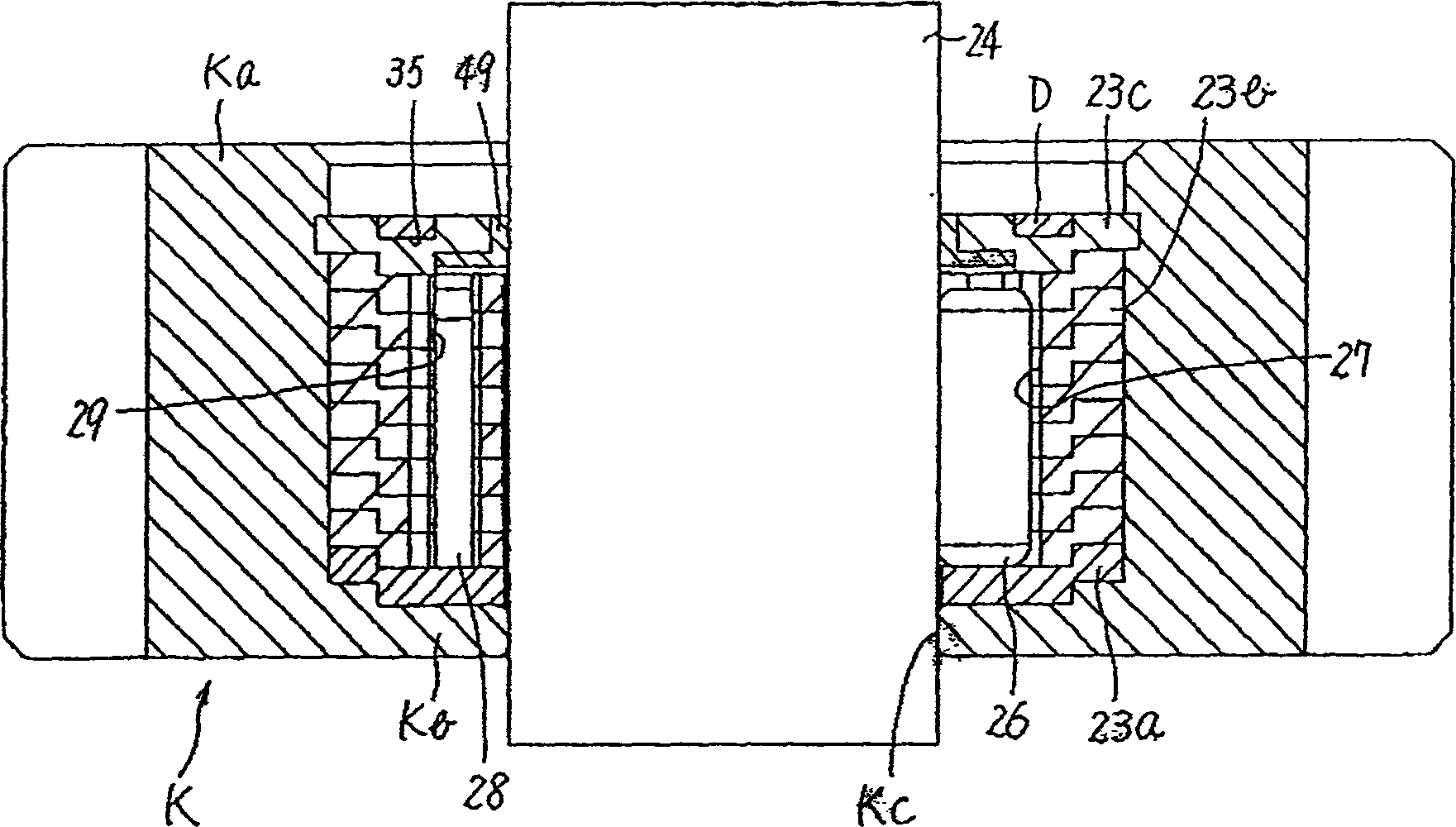

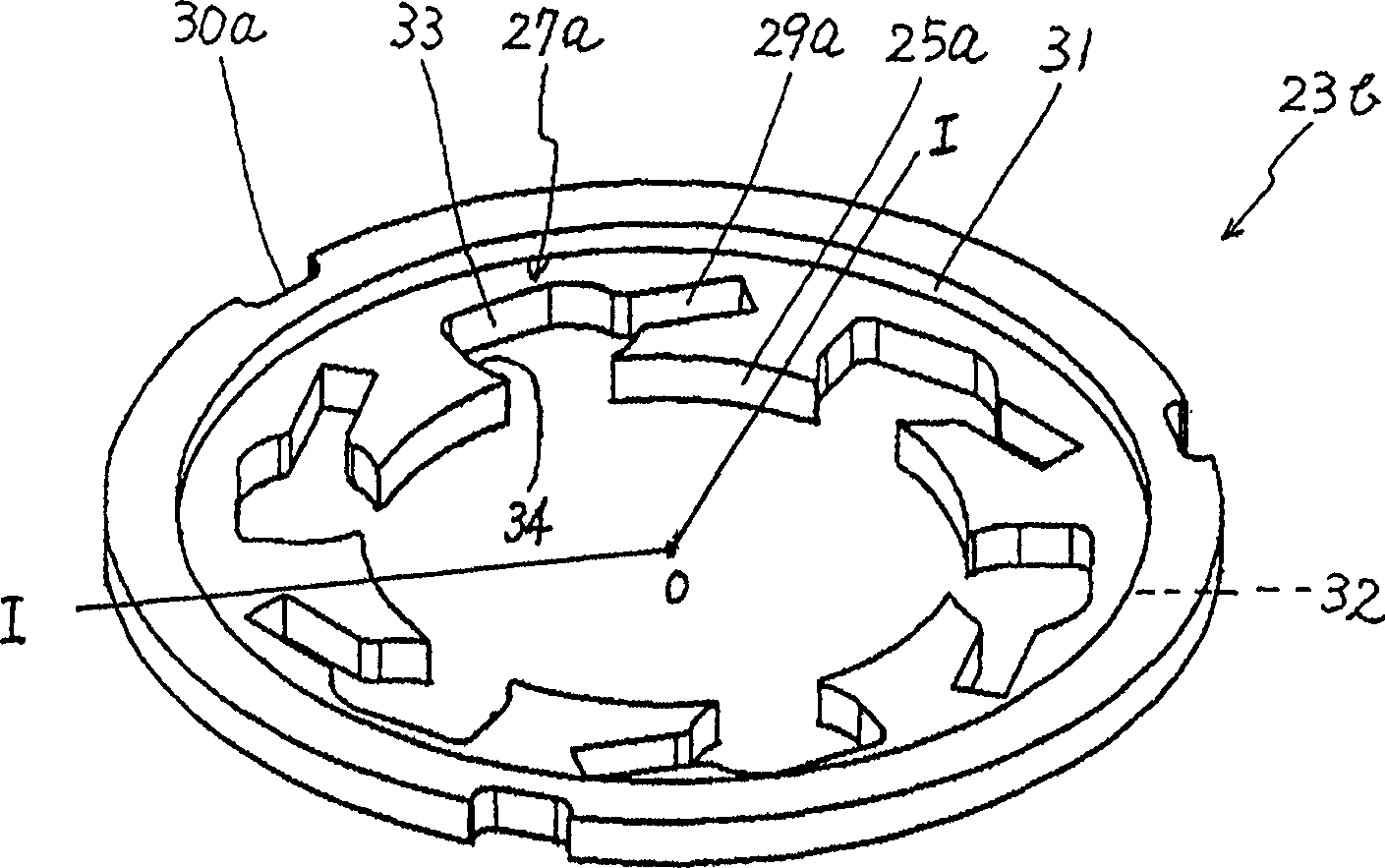

[0051] figure 1 ~5 shows embodiment 1 of the present invention. The most important feature of the present invention is that the metal plate member is stamped by press processing, and the stamped plate member is laminated to form the bearing bush 22 of the one-way overrunning clutch, and a press-fit part is formed around the entire circumference of the bearing bush 22. The structure other than these features is the same as the conventional case, so its detailed description will be omitted.

[0052] figure 1 Shown is an overall view of the bearing bush 22 of Embodiment 1, figure 2 It is a cross-sectional view when the bearing bush 22 is installed in the outer ring K and the rotating shaft 24 is inserted into the bearing bush 22 . the above figure 2 The shown outer wheel K is designed as a gear part, and the outer wheel K can also be designed and utilized as a pulley component or other components in addition to the above-mentioned gear components. As above figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com