Polarized light film and its manufacturing method, optical film and image display device

一种偏振光薄膜、制造方法的技术,应用在光学、层压装置、光学元件等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

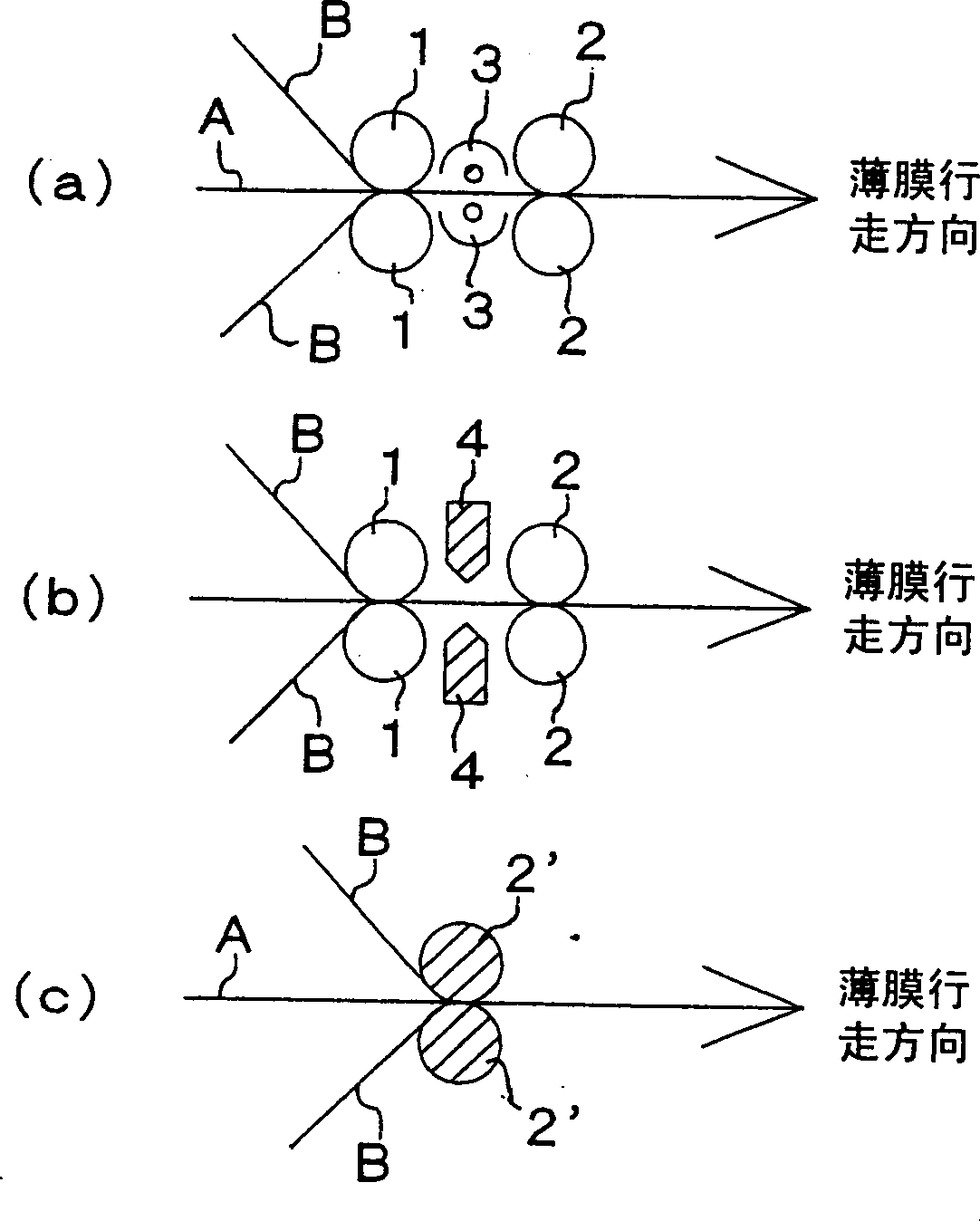

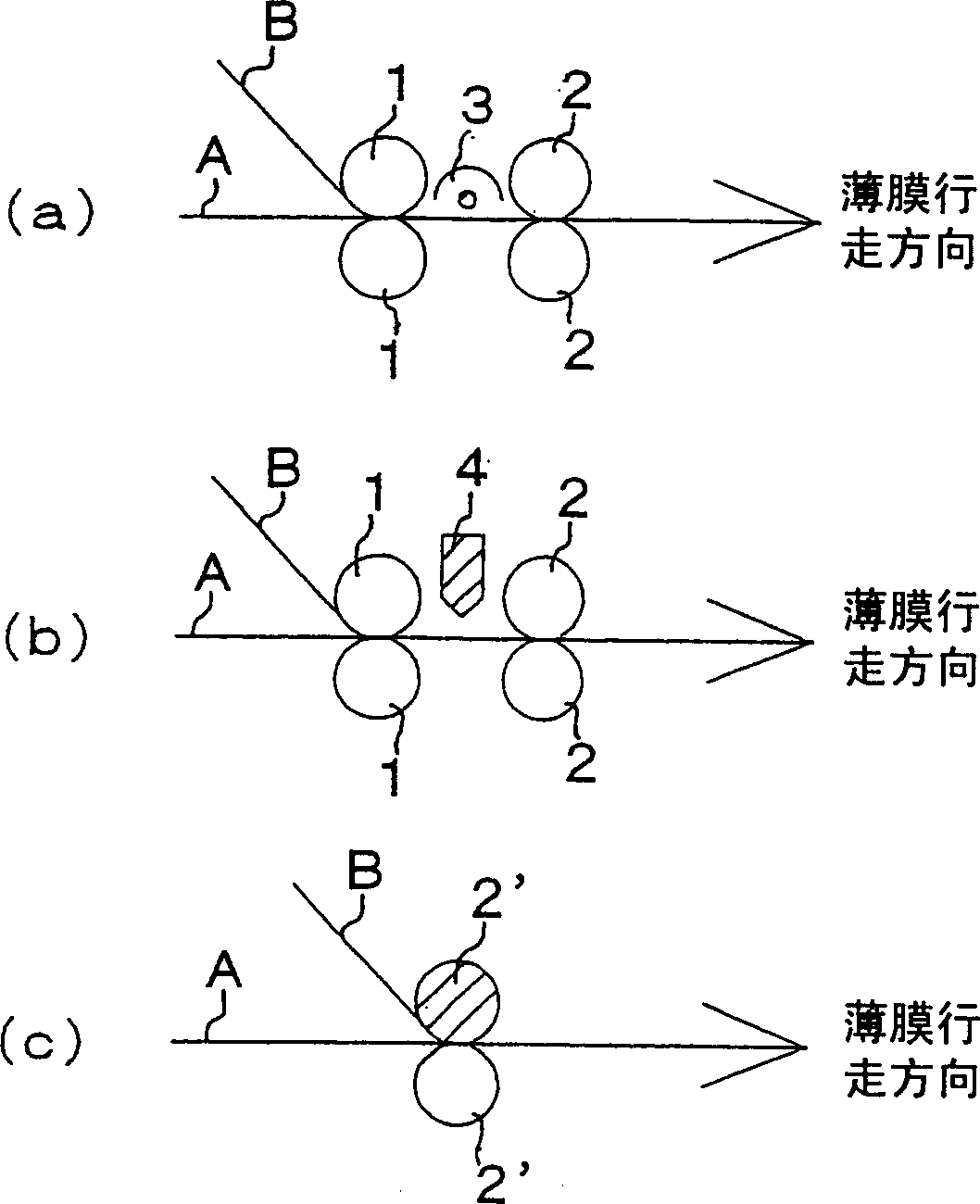

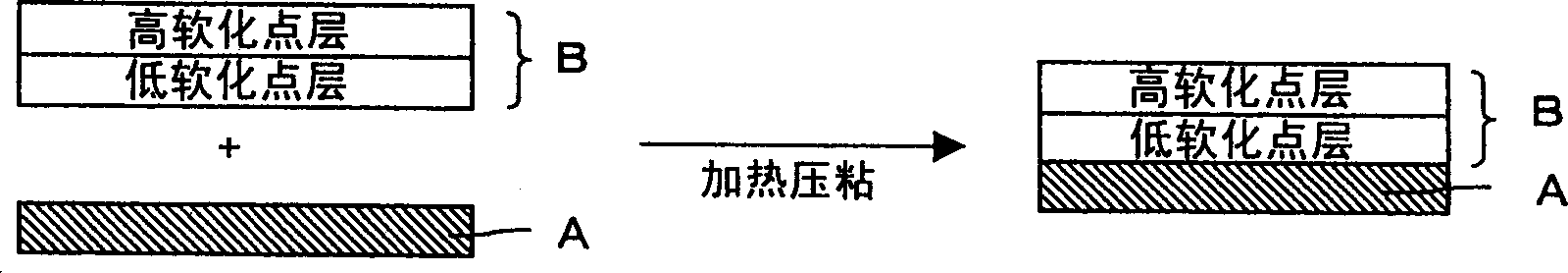

[0072] Such as figure 1 As shown in (a), a protective film with a softening point of 125°C is pasted on both sides of the polarizer, passed through the conveying roller, heated to 130°C by the IR heater, and laminated by pinch rollers to obtain polarized light film. The heating time (passage time between the rolls) was 2 seconds, and the linear pressure of the pinch rolls was 20 N / cm. The obtained polarizing film polarizer was bonded to the protective film, and there was no problem in appearance.

Embodiment 2

[0074] Such as figure 1 As shown in (b), a protective film with a softening point of 125°C is pasted on both sides of the polarizer, passed through a conveying roller, heated to 130°C by hot air, and laminated by pinch rollers to obtain a polarizing film. The heating time (passage time between the rolls) was 4 seconds, and the linear pressure of the pinch rolls was 40 N / cm. In the obtained polarizing film, the polarizer was bonded to the protective film, and there was no problem in appearance.

Embodiment 3

[0076] Such as figure 1 As shown in (c), a protective film with a softening point of 125° C. is pasted on both sides of the polarizer, and laminated by pinch rollers heated to 130° C. to obtain a polarizing film. The heating time (passage time between the rolls) was 0.1 second, and the linear pressure of the pinch rolls was 20 N / cm. The obtained polarizing film polarizer was bonded to the protective film, and there was no problem in appearance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com