Drawbench for drawing long and thin material

A technology of slender materials and drawing machines, which is applied in the field of drawing machines, can solve the problem that the stroke frequency cannot be increased arbitrarily, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

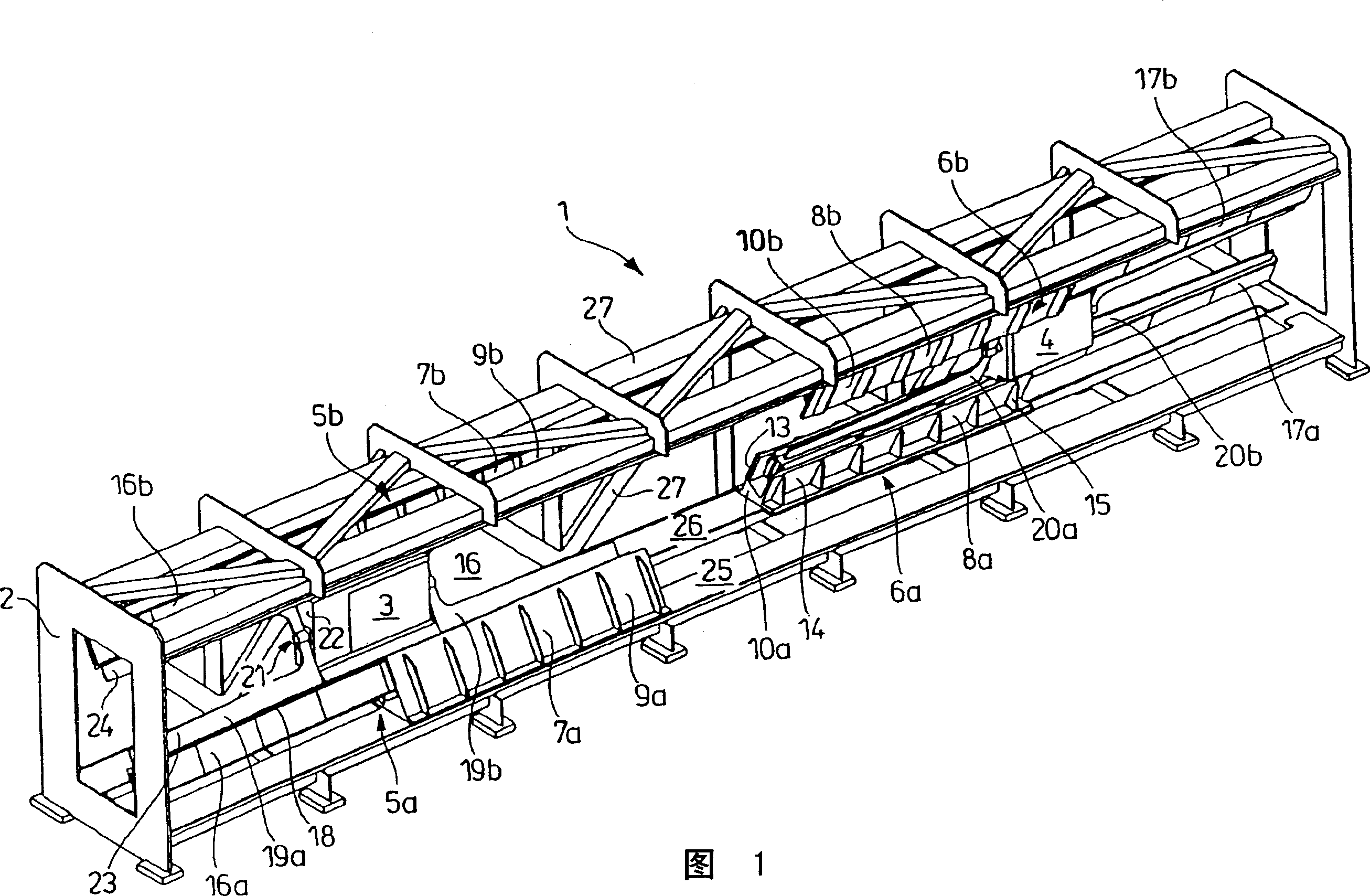

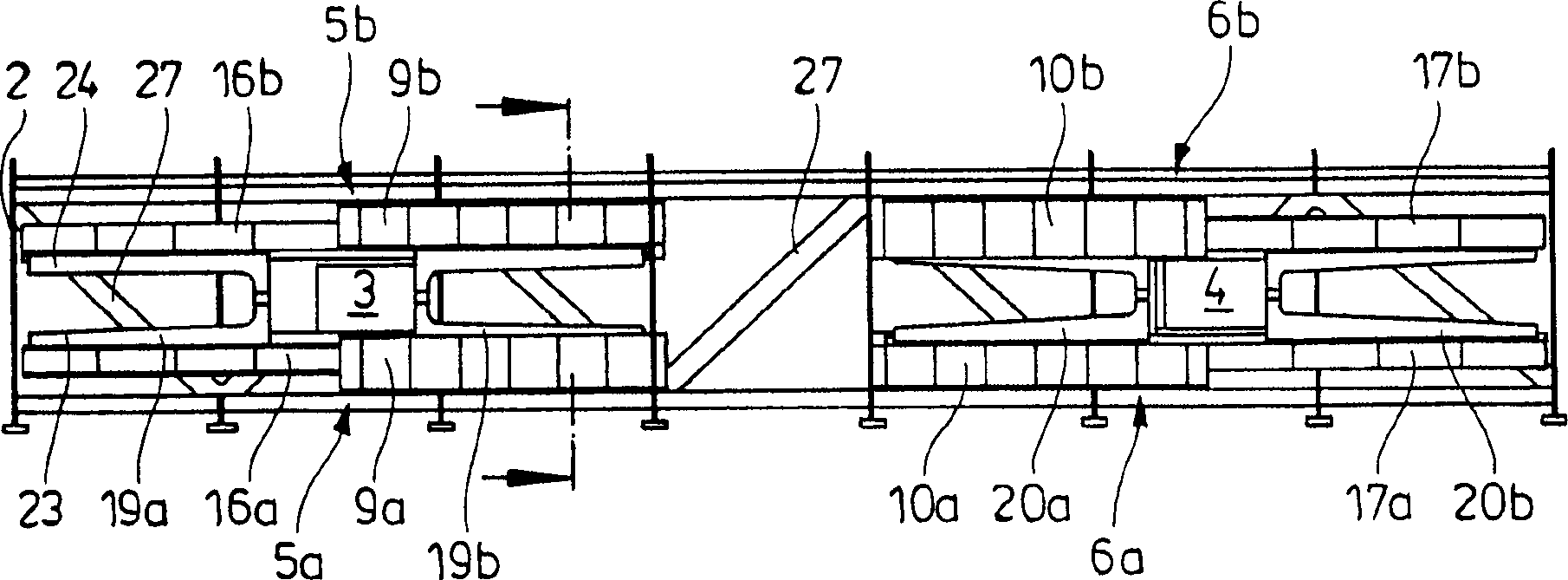

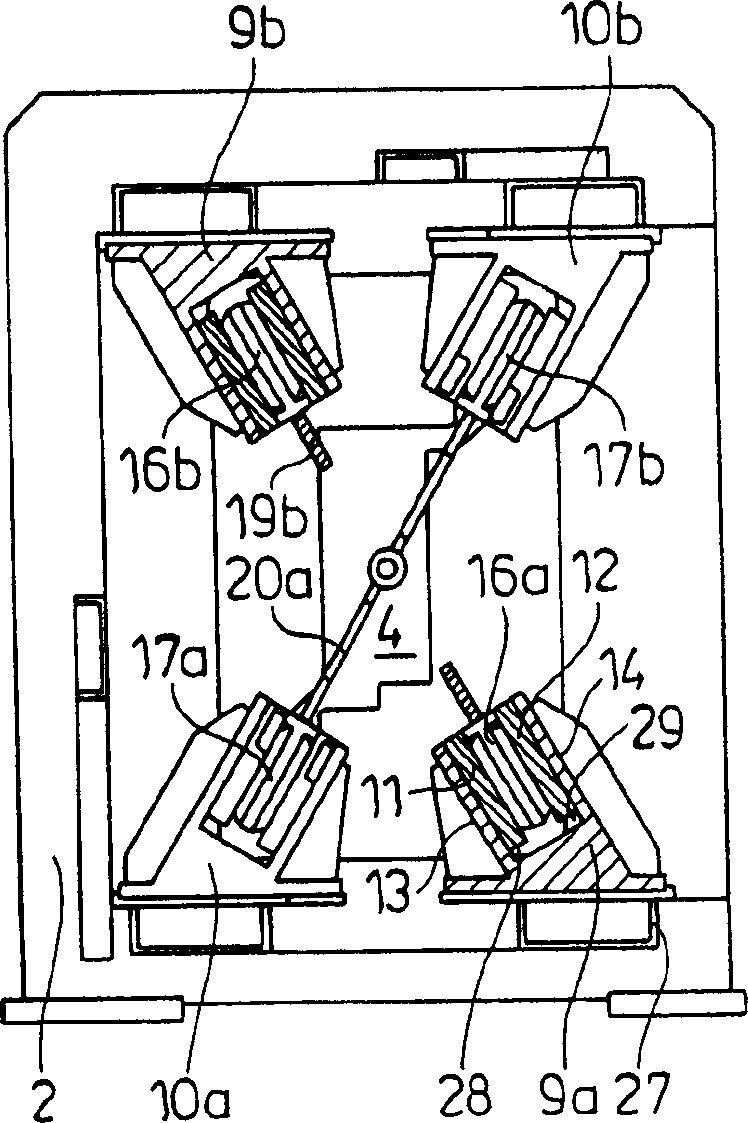

[0030] FIG. 1 shows a drawing machine with a frame 2 and a drawing unit arranged in the frame. The drawing unit consists of a drawing die (not shown) and two drawing carriages 3, 4, these two carriages operate in a hand-in-hand manner, and pull the drawing material through the drawing die, such as a Root canal or a rod (not shown). To this end, two drawing carriages 3, 4 (one of which may be a combined pre-drawing and drawing carriage) are each driven by two linear motor drives 5a, b; It moves along a track formed by a linear motor drive in the direction. The track is part of two linear motor drives comprising a first (upper) and a second (lower) track section 7b, 8b; 7a, 8a. In the embodiment shown, the track sections 7a, b; 8a, b are formed by fixed primary parts of the linear motor drives 5a, b; 6a, b. One (7b, 8b) of the two track parts is fixed on the upper part of the frame 2, and the other (7a, 7b) is fixed on the lower part of the frame 2. The two track parts are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com