Film light filter for preventing glass from cracking, and plasma display

A plasma and optical filter technology, applied in glass/slag layered products, film/flaky adhesives, gas discharge tubes/containers, etc. Issues such as weight and cost are not resolved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] Add 100 parts of 2-ethylhexyl acrylate and 0.1 part of 2,2-diphenyl-2-methoxy Acetophenone (photopolymerization initiator) was polymerized by irradiation with ultraviolet light, thereby obtaining a viscous liquid of 10% by weight of a polymerized polymer-monomer mixture, and in this viscous liquid, 0.2 parts of trimethylolpropane triacrylic acid was added ester (internal crosslinking agent) and 0.1 part of 2,2-dimethoxy-2-phenylacetophenone (photopolymerization initiator) to prepare a photopolymerizable composition.

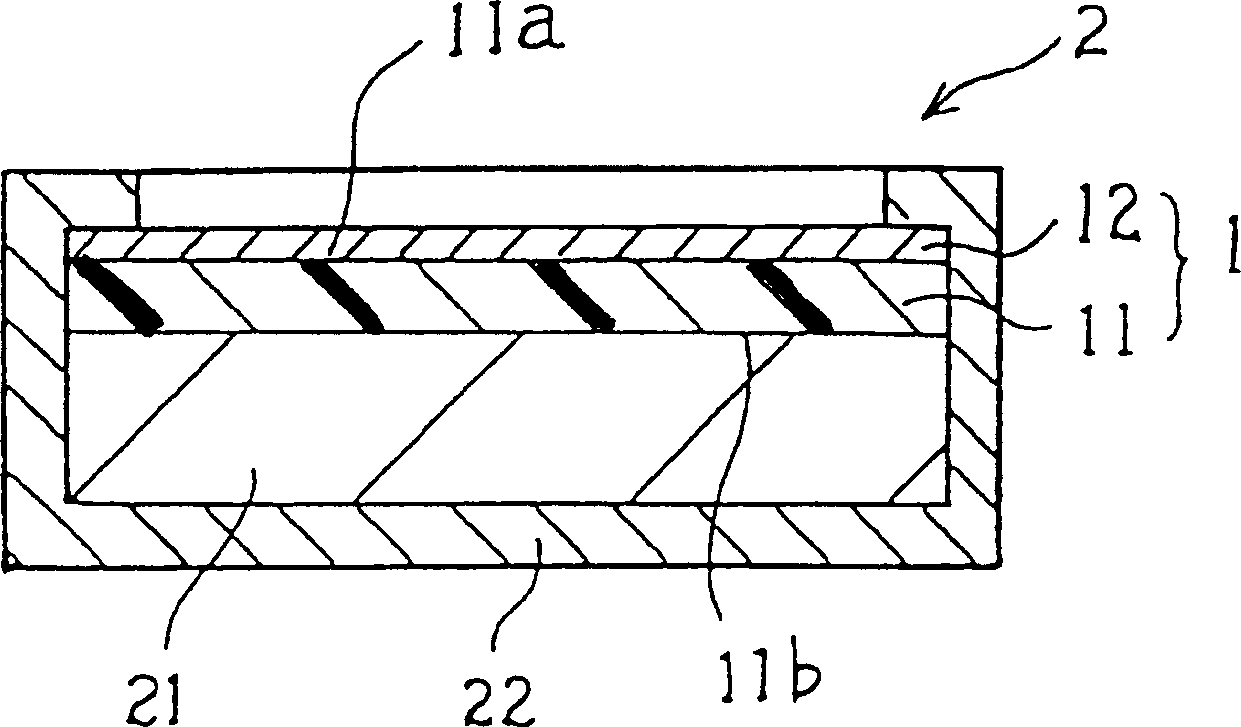

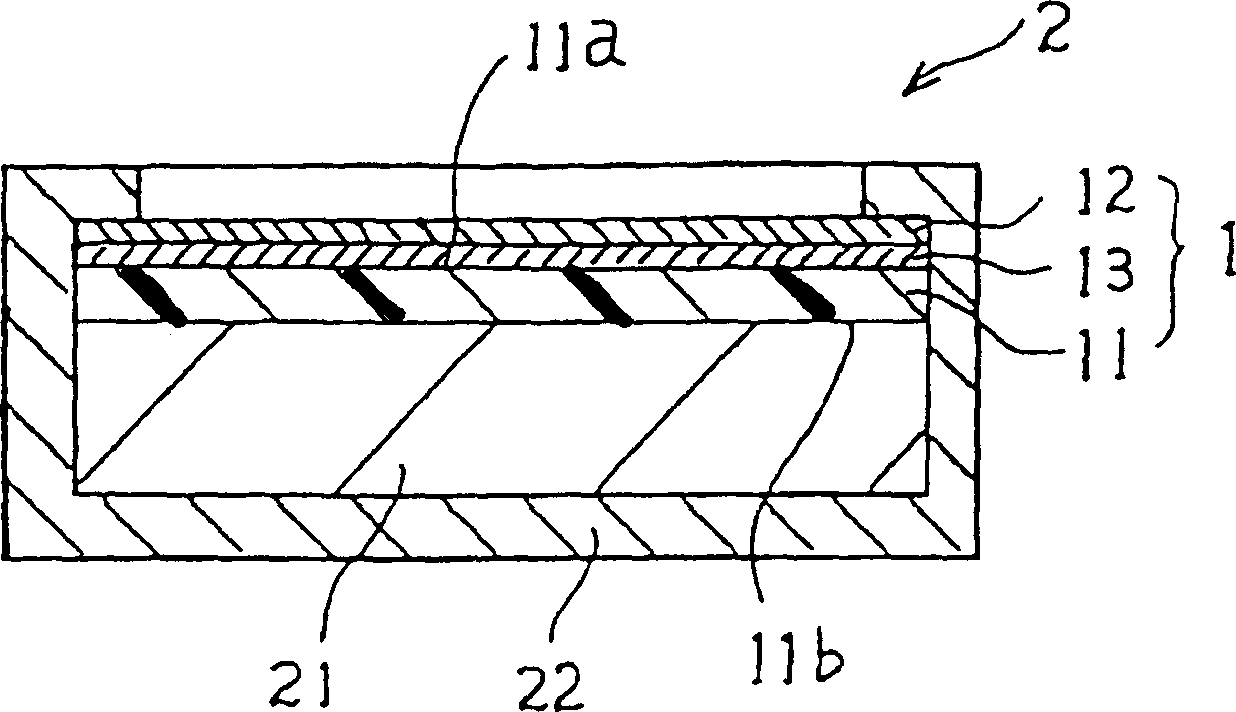

[0046] The photopolymerizable composition was applied to a 50 μm thick polyester separator and passed through a 2000 mj / cm 2UV irradiation to form a 1mm thick acrylic pressure sensitive adhesive base layer. The base layer was used as a single-layer structure type glass crack prevention layer, so that a 0.1 mm thick antireflection film ("Realook A-1200" produced by NOF Corporation) was bonded to one surface of the base layer, thereby producing a glass crac...

example 2

[0048] A glass-crack-preventing film-like filter was produced in the same manner as in Example 1, except that the coating thickness of the photopolymerizable composition was changed so that the thickness of the glass-crack-preventing layer made of an acrylic pressure-sensitive adhesive was 2 mm .

example 3

[0050] A glass-crack-preventing film-like filter was produced in the same manner as in Example 1, except that the coating thickness of the photopolymerizable composition was changed so that the thickness of the glass-crack-preventing layer made of an acrylic pressure-sensitive adhesive was 3 mm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com