Passive direct loaded disk spring tension compensator

A disc spring and compensator technology, applied in the direction of overhead lines, etc., to achieve the effect of high utilization rate of disc spring, convenient debugging and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

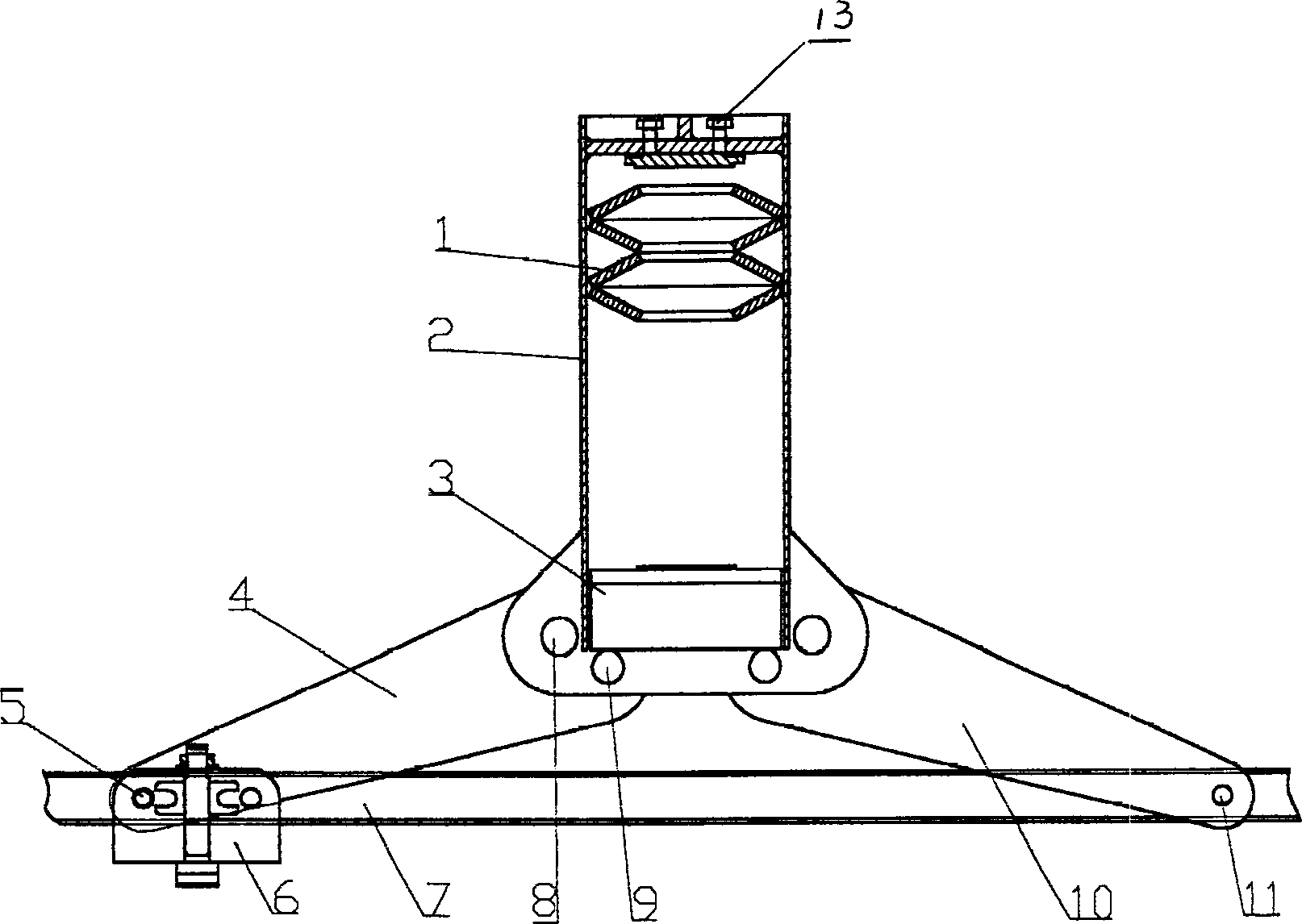

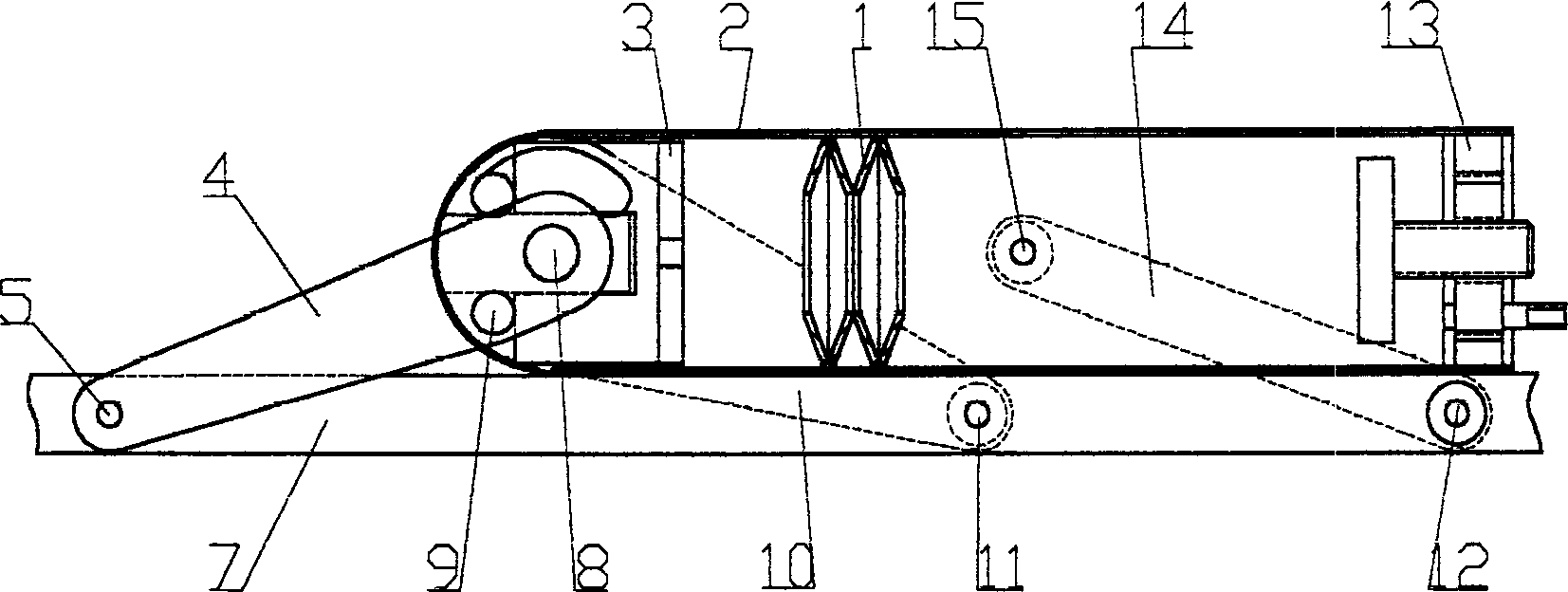

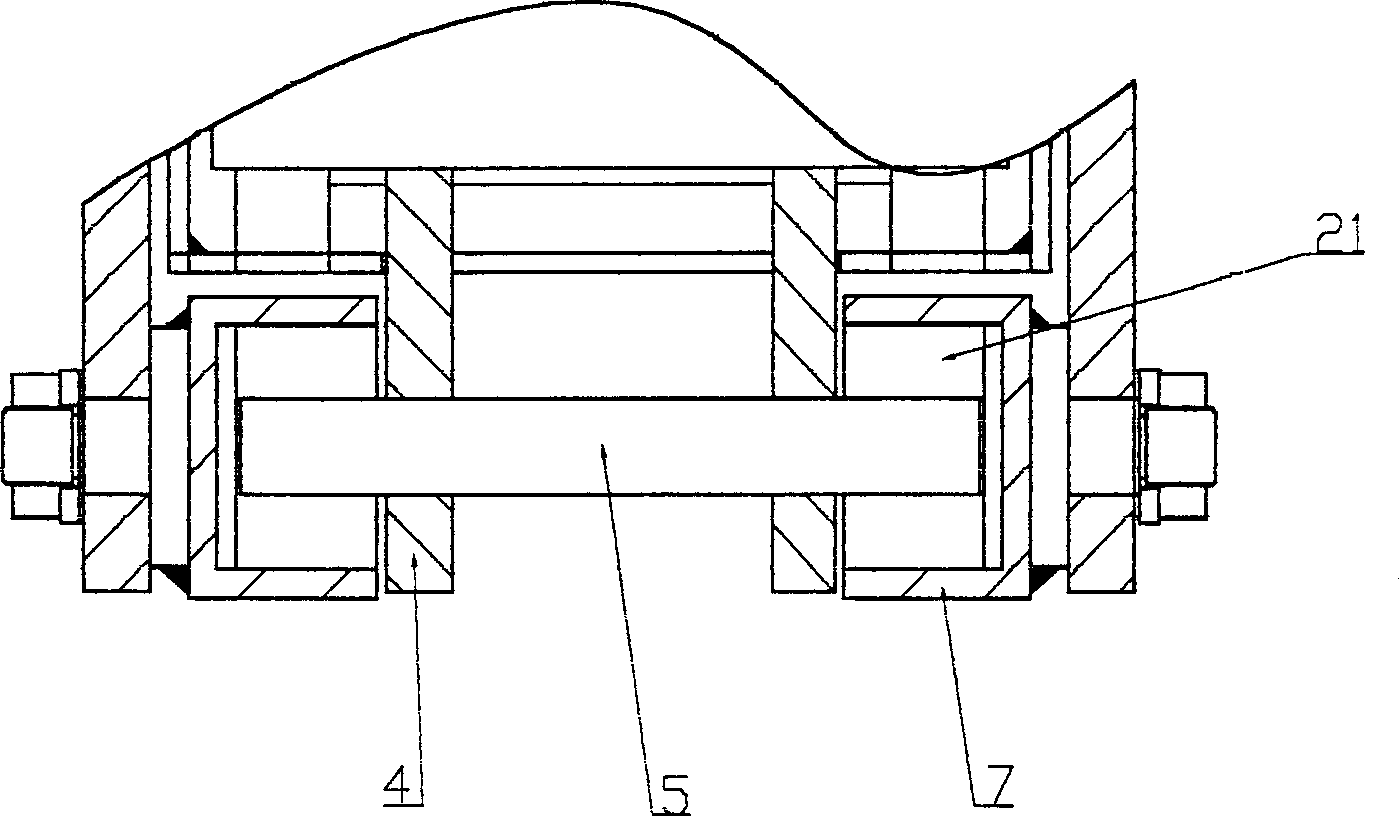

[0016] Depend on figure 1 It can be seen that, for the tension compensator with double-spindle structure, disc spring groups 1 are placed in pairs in the casing 2, and the front port of the casing 2 is provided with a pressure plate 3, and the shifting rotary arm 4 and the positioning rotary arm 10 are symmetrical through their independent spindles 8. The movable connection is on both sides of the center of the front port section of the shell 2, the final shaft 9 for positioning the rotary arm 10 and one end of the shifting rotary arm 4 is pressed on the pressure plate 3, the base 7 is strip metal, and the base 7 is provided with horizontal grooves and Through the vertical slot, the other end of the shifting rotary arm 4 slides in the horizontal slot through the ground load adjustment mechanism 6, and the other end of the positioning rotary arm 10 is fle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com