Vibratory soil (snow) dipper

A vibrator and ripper technology, which is used in snow surface cleaning, cleaning methods, mechanically driven excavators/dredgers, etc., can solve the problems of discounted operation efficiency, low operation efficiency and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

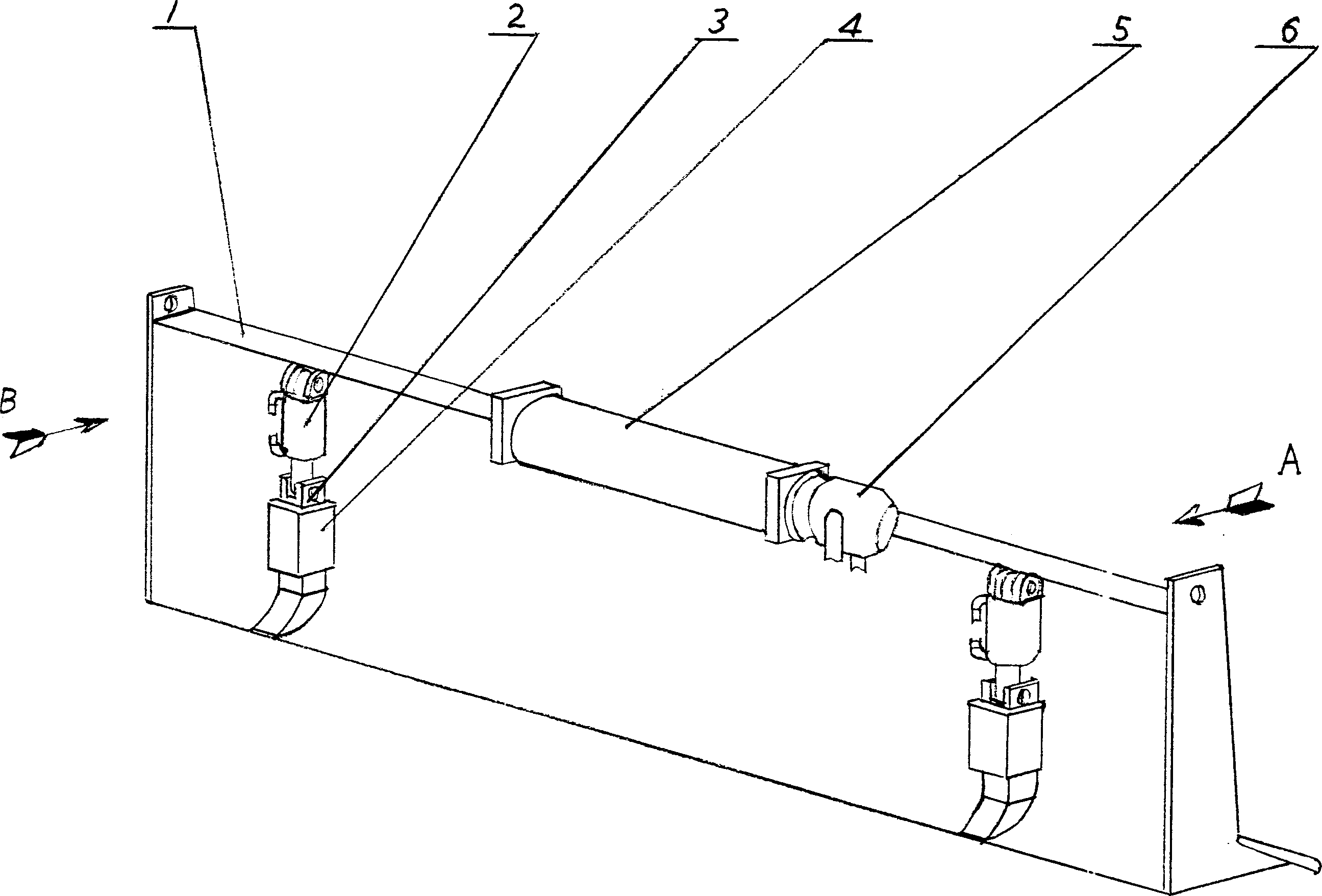

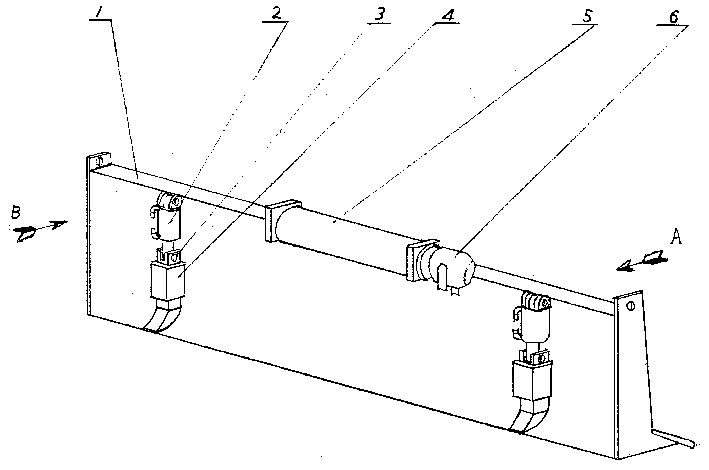

[0006] On the non-working surface (B) of existing bulldozing (snow) shovel (1), vibrator (5) has been installed; The motor (6) on this vibrator can be hydraulically driven, also It can be driven by electricity; in addition, this bulldozing blade can also be installed with several rippers; this ripper is composed of a hydraulic cylinder (2), a guide body (4) and a ripper tooth (3); The vibrator should match the working quality of the bulldozing (snow) shovel. Its power comes from the hydraulic source or power supply of the main engine. The hydraulic cylinder of the ripper is connected with a hydraulic source through a pipeline, a control valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com