Spiral paring knife for rapidly paring large quantities of pineapples applicable to canning factory

A technology for cutting large quantities of spiral blades, which is applied in the field of spiral cutting knives to achieve the effects of easy cutting, reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

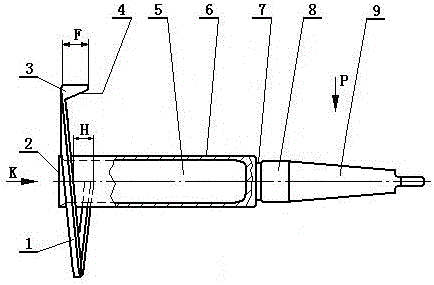

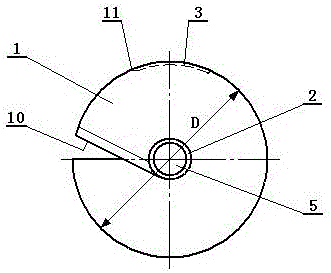

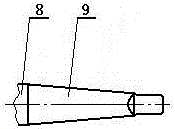

[0026] Embodiment: the right end of cutter bar 6 is provided with the No. 2 Morse taper shank 9 that matches with the taper hole of the drill bit cover of drilling machine.

[0027] The left end of the No. 2 Morse taper handle 9 is provided with a neck 8, and the left end of the neck 8 is provided with an undercut 7.

[0028] The working process of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0029] The working process of the present invention is: when needing to cut pineapples, insert No. 2 Morse taper shank of the present invention into the taper hole of the drill bit sleeve of the drill press and tighten it, so that the drill press can be used to quickly cut pineapples.

[0030] When cutting pineapple, first cut off a section of the upper part of the pineapple long leaf, place the lower part of the long root of the pineapple downwards in the special clamp on the drilling machine workbench, start the drilling mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com