Intelligent processing technology of tea set and production method of environmentally friendly tea tray

A production method and technology of tea sets, which are applied in the field of mechanical processing, can solve problems that affect product quality and are prone to burrs, and achieve the effects of improving aesthetics, not being stuck easily, and reducing the workload of repairing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

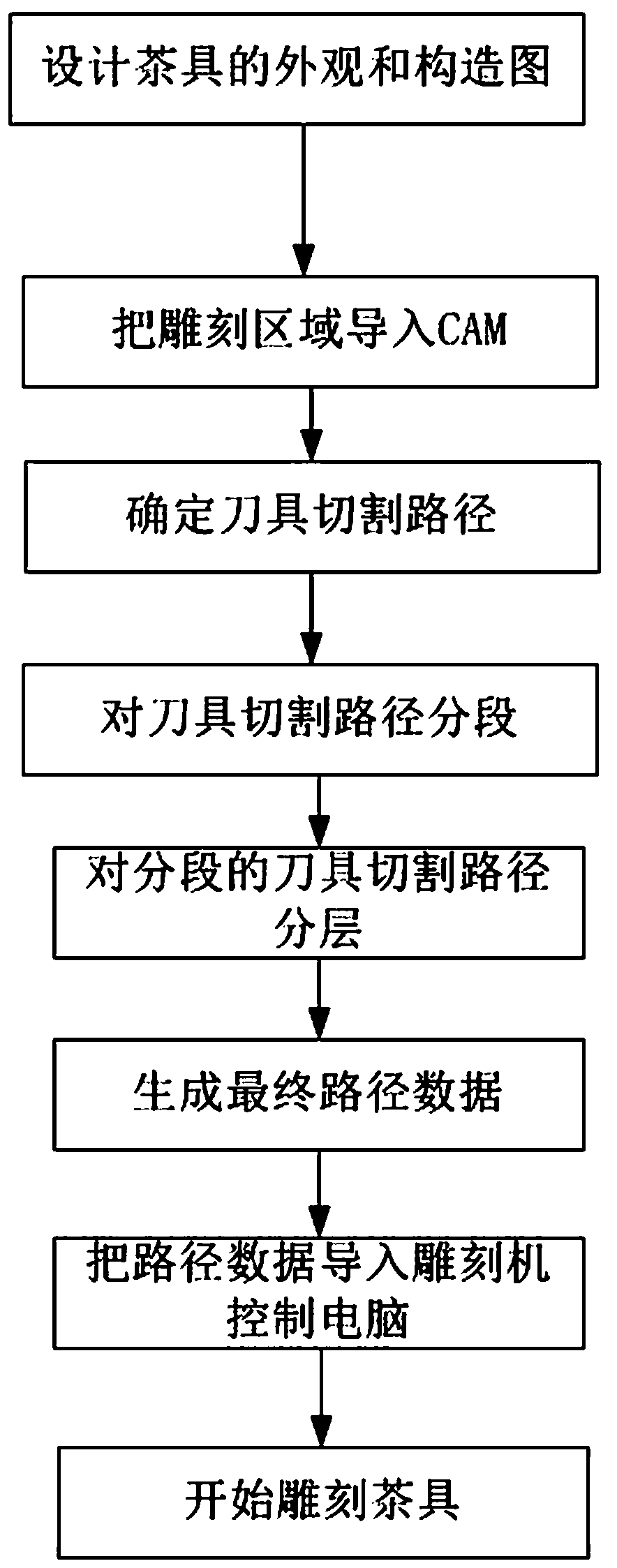

[0048] Consumers tell designers about the appearance characteristics of tea trays that need to be customized. Designers design the appearance and structural drawings of tea trays according to consumer requirements and equipment processing capabilities, form electronic documents, and import relevant data of structural areas that can be engraved and processed by engraving machines. To the CAM module of the engraving machine, the cutting path is generated, and then the cutting path is segmented and layered according to the tool and graphic structure, and the final path data is generated, and submitted to the control computer of the engraving machine, which controls the engraving machine for engraving production, and finally by The tea set carved by the engraving machine is manually cleaned and the surface is finely treated, and the final product is delivered to the customer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com