Fastening clamping assembly and connecting structure therewith

A technology for connecting structures and fixtures, applied in the direction of connecting components, furniture connections, connections, etc., can solve problems such as joint failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Specific implementation

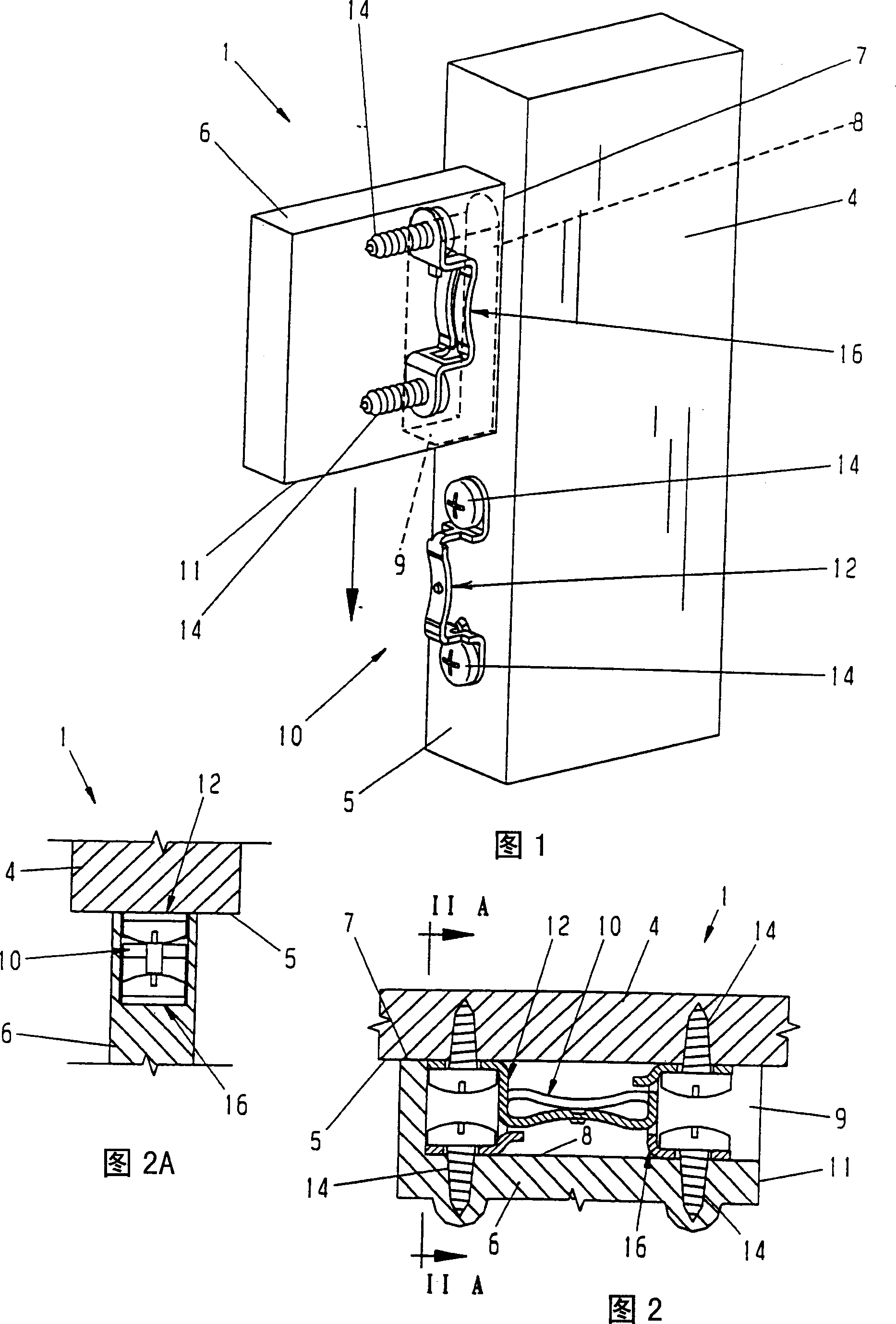

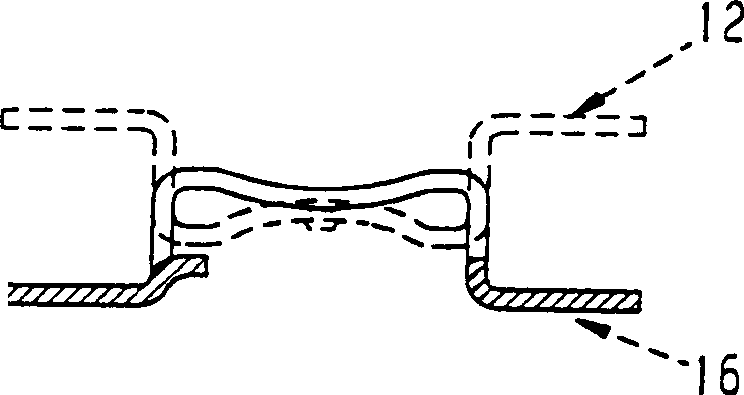

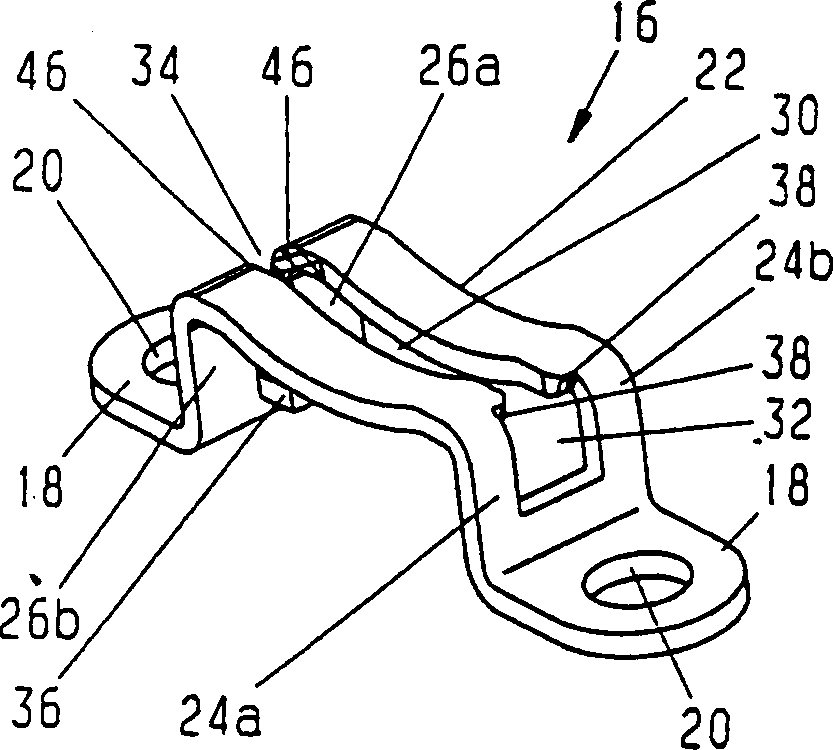

[0061] Figures 1, 2 and 2A show a typical connection structure 1 in which the clamp assembly 10 of the present invention is used, such as a furniture assembly, in this case the legs or supports 4, beams or horizontal supports of tables, chairs, etc. 6 can be installed on it by the present invention. The vertical support or leg 4 includes a side 5 on which one of the two parts of the clamp assembly 10 (in this case a convex clamp) is fixed by a screw 14. The horizontal support or beam 6 includes a distal edge 7 in which a pocket or groove 8 is formed, the groove 8 having a bottom surface, and the second part of the clamp assembly 10 (in this case a slotted concave clamp 16 ) Is still fixed on the bottom surface by a pair of mounting screws 14. The pocket 8 has a window or opening 9 extending through the vicinity of the beam 6 or the bottom surface 11 so that, as described more fully below, when the beam 6 is moved downward, the clamps 12 and 16 enga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com