Press button type switch and its producing method

A switch and button technology, applied in the field of button switches and its manufacturing, can solve problems such as poor contact and achieve the effect of preventing cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

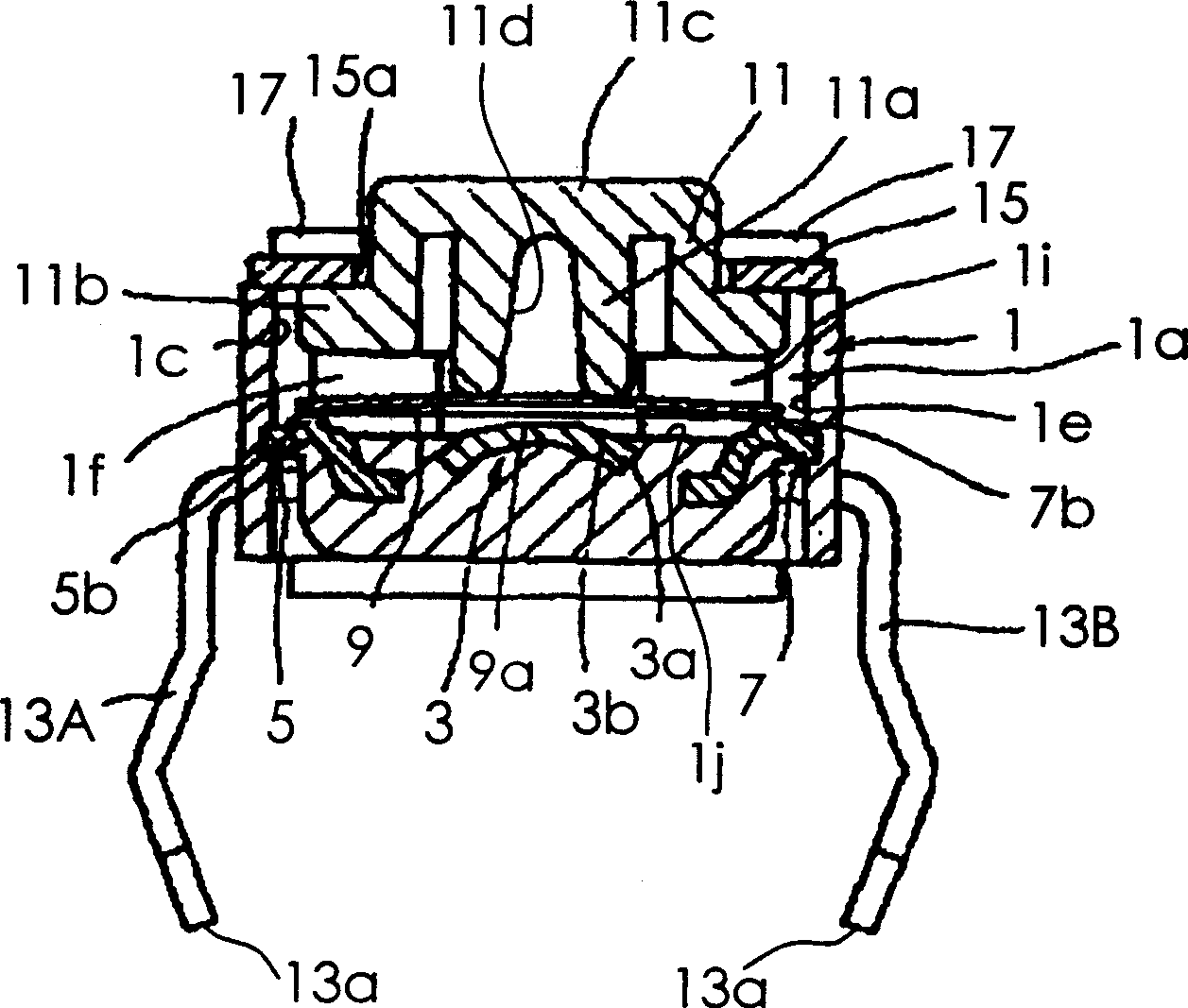

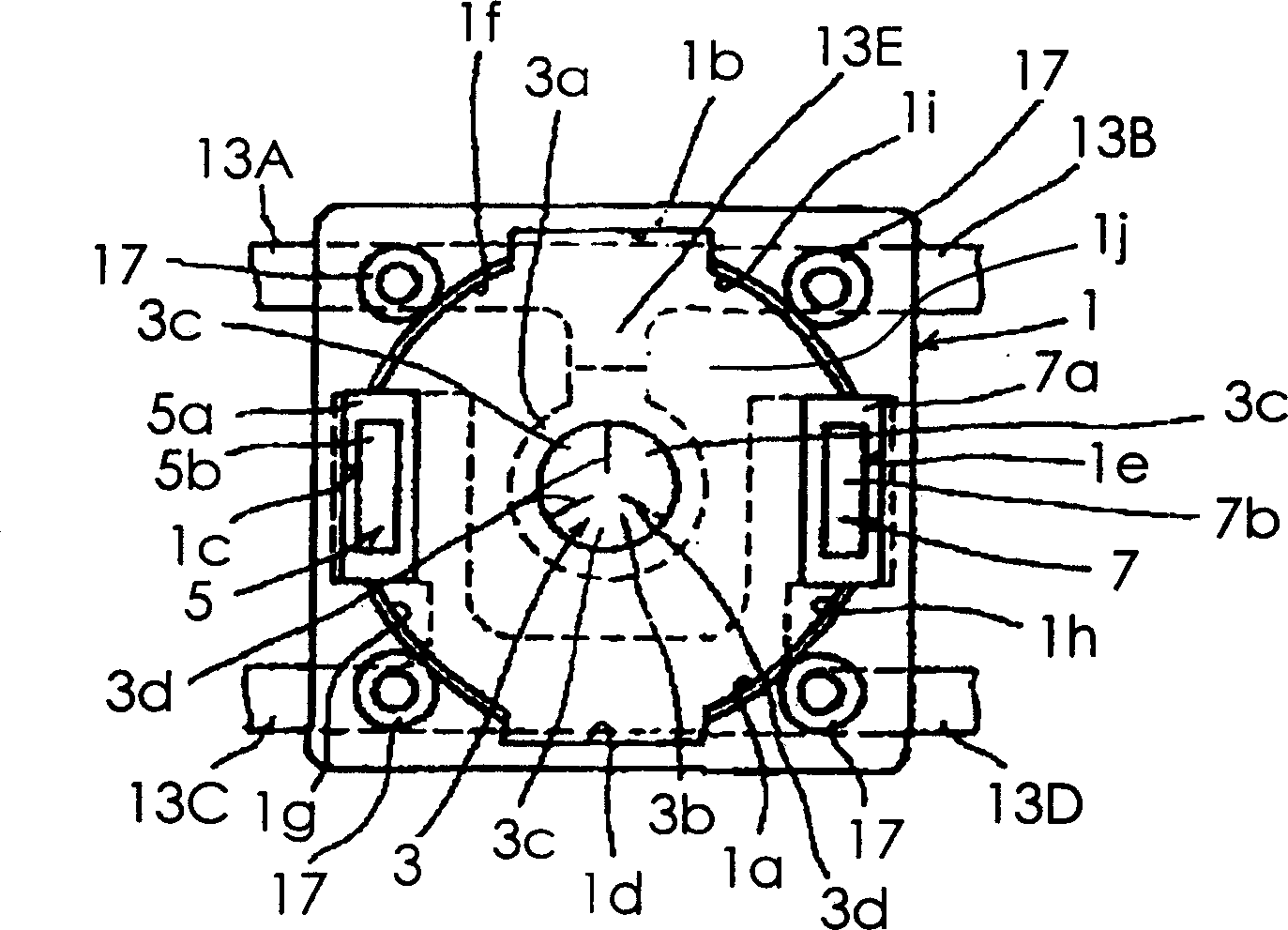

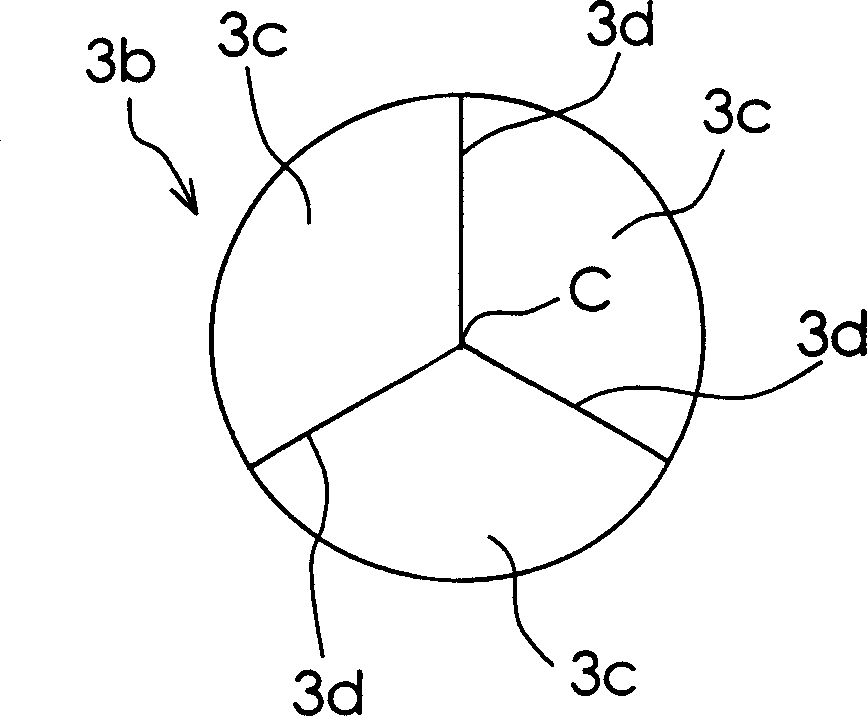

[0020] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a schematic cross-sectional view of a push-button switch according to an embodiment of the present invention, figure 2 Yes figure 1 The shown top view of the insulating case main body of the push-button switch viewed from the side of the opening of the recess. As shown in each figure, the push button switch of this embodiment has an insulating case main body 1, a central contact 3, a pair of end contacts 5, 7, a movable contact 9, and an operating member 11. The insulating case main body 1 has a quadrangular prism shape, and a cylindrical recess 1a opening upward is formed inside. The inner surface of the concave portion 1a has flat surfaces 1b to 1e having flat surfaces projecting in four directions and curved surfaces 1f to 1i connected to the flat surfaces 1b to 1e at intervals of 90°. These curved surface portions 1f to 1i respectively for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com