Ultrasonic vibration bottle-rolling device

A technology of ultrasonic wave and roller bottle, which is applied in transportation and packaging, shaking/oscillating/vibrating mixer, dissolving, etc. It can solve problems such as unfavorable operation, inability to mix uniformly at the same time, and mass production requirements to be negotiated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

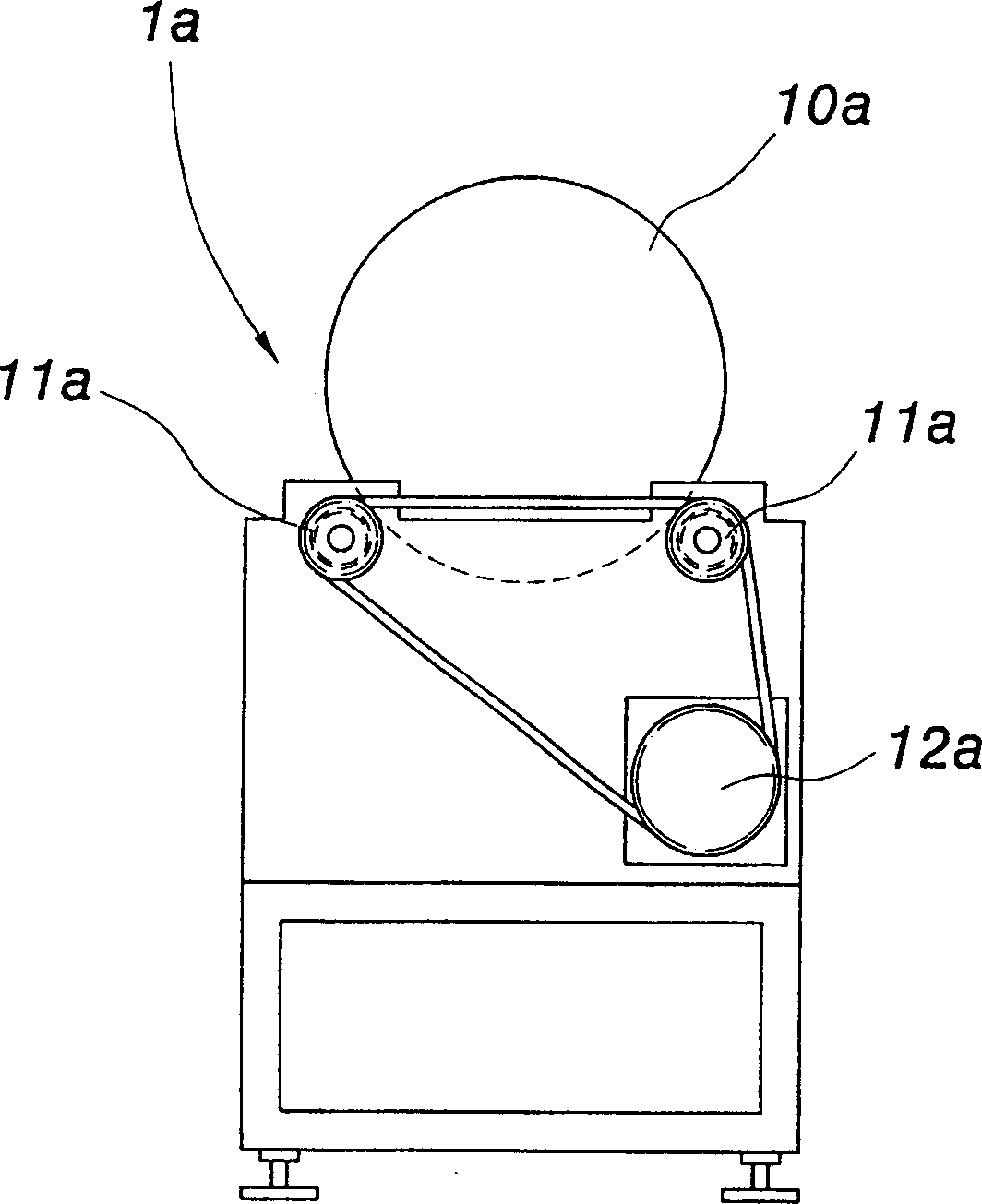

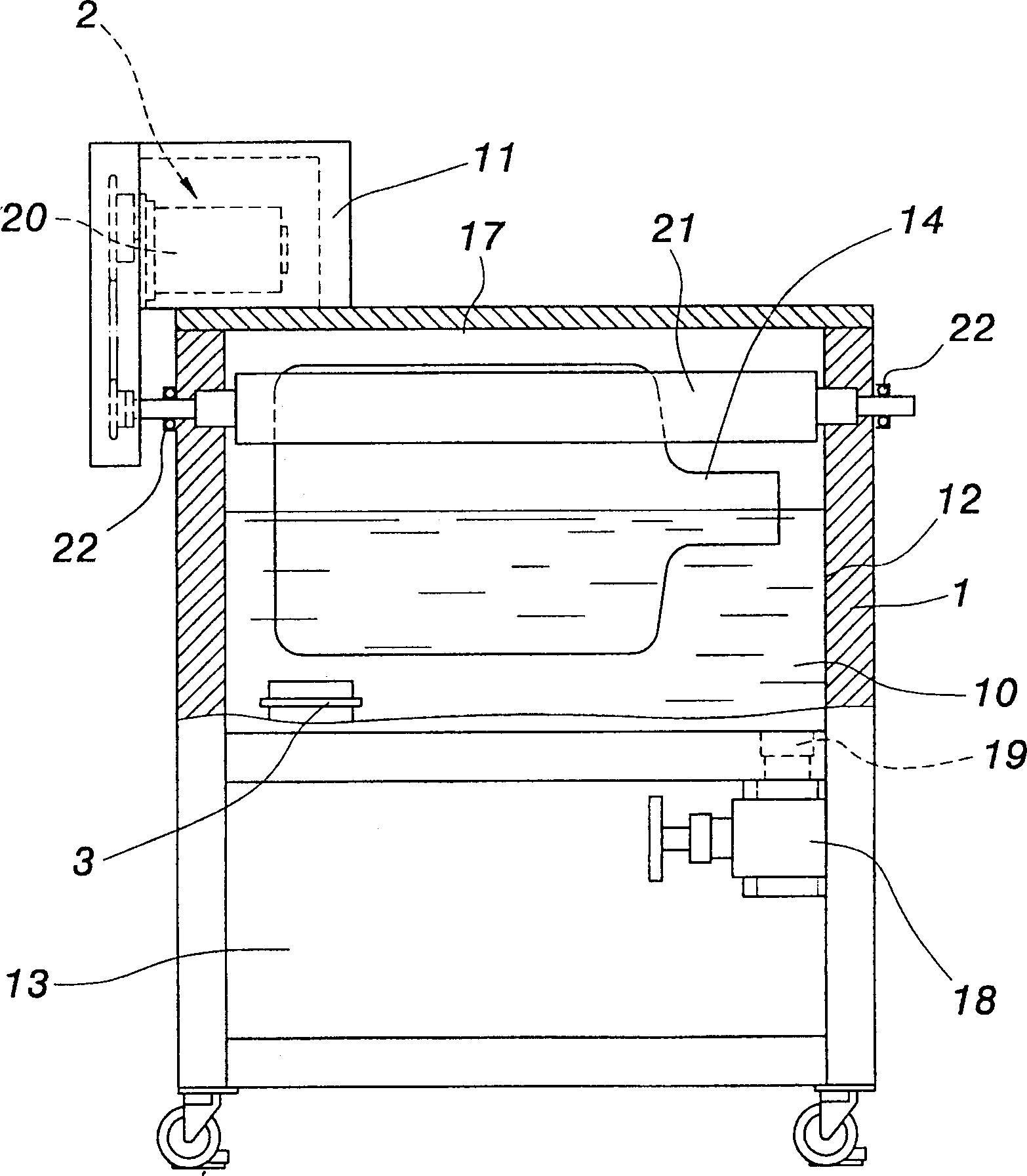

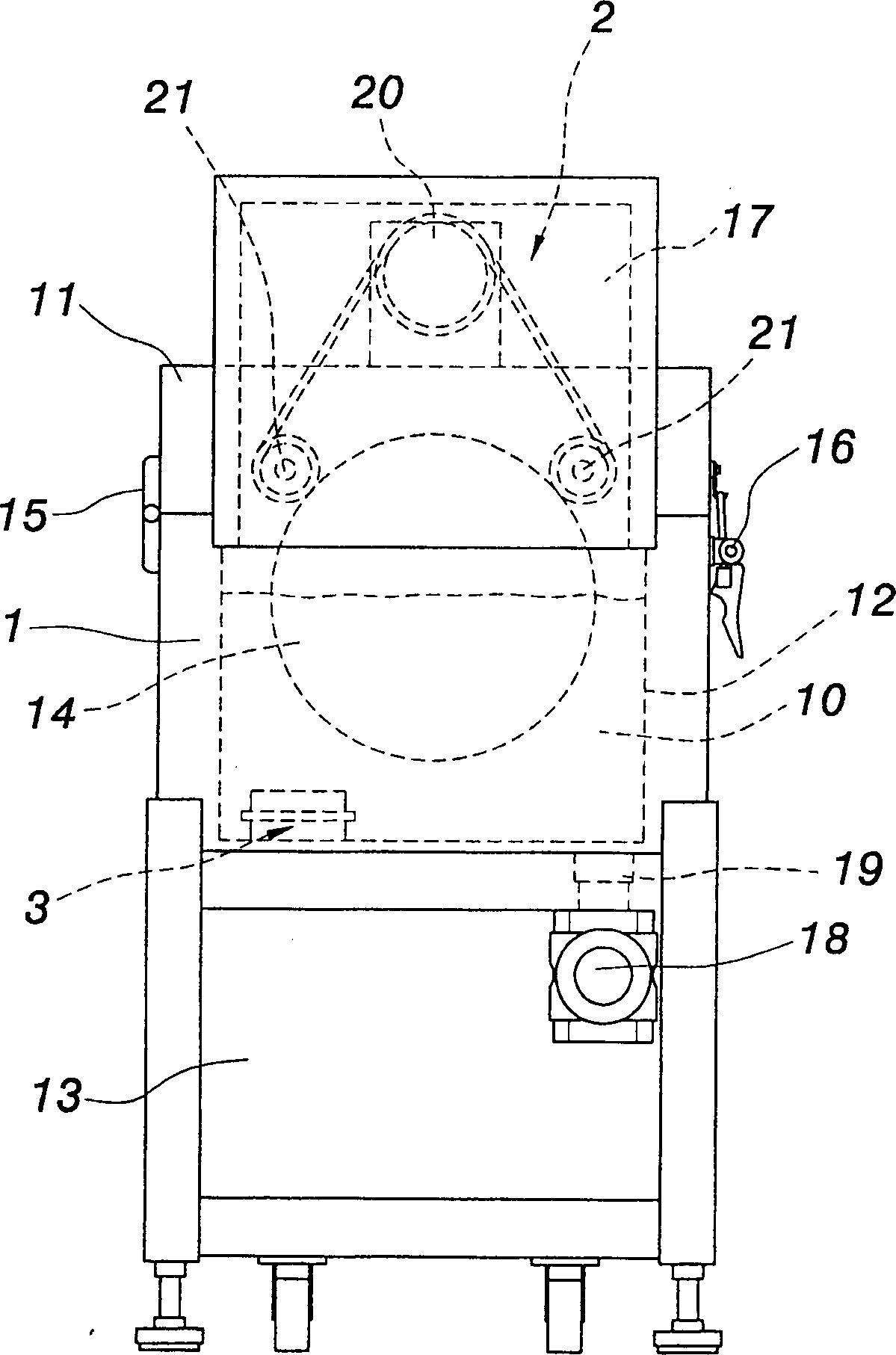

[0013] see figure 2 , image 3 and Figure 4 , which are respectively the front view sectional schematic view and the side view sectional schematic view of the closed state and the open state of the present invention. The invention provides an ultrasonic vibration roller bottle device, which uses a circular roller bottle to mix a plurality of built-in liquid or solid raw materials, and provides these raw materials for the preparation of mixing under the required vibration conditions; The ultrasonic oscillating roller bottle device includes a tank body 1, a rolling mechanism 2 and an ultrasonic oscillator 3; wherein, the tank body 1 is hollow inside and can be used to accommodate liquid 10, and the tank body 1 is provided with an upper The cover 11 can form a closed space 12 inside the tank body 1 by closing the upper cover 11 , and a base 13 can be provided below for support and positioning.

[0014] The loam cake 11 above this tank body 1 is movable type, can make this ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com