Integrated optical device and method of formation

A technology of Bragg gratings and substrates, applied in optics, optical components, light guides, etc., can solve problems such as expensive and complicated manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

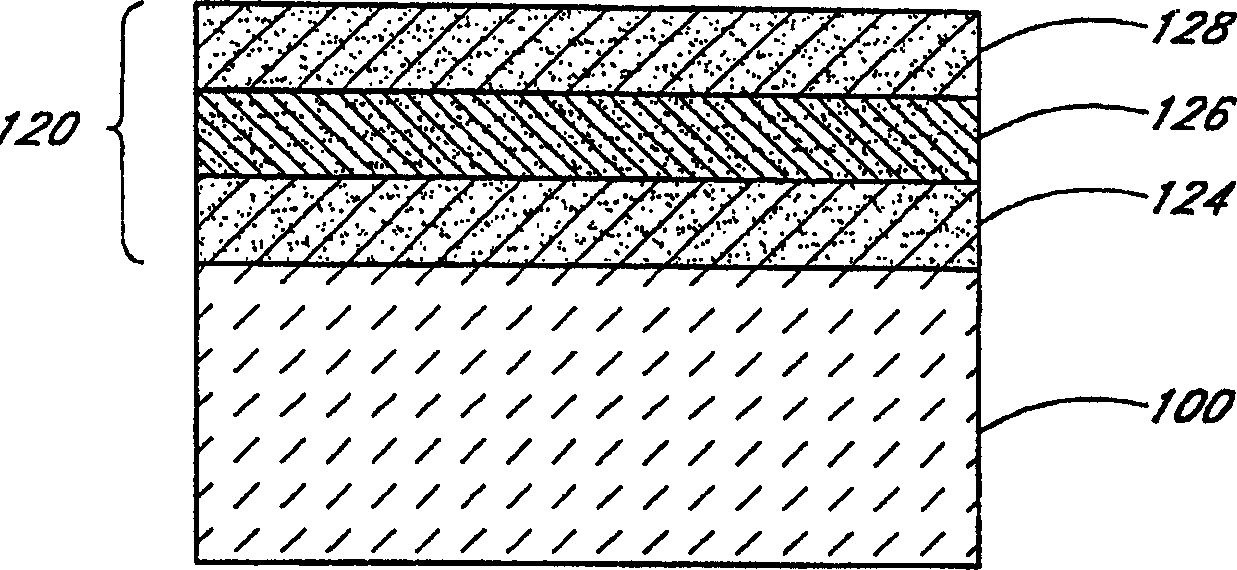

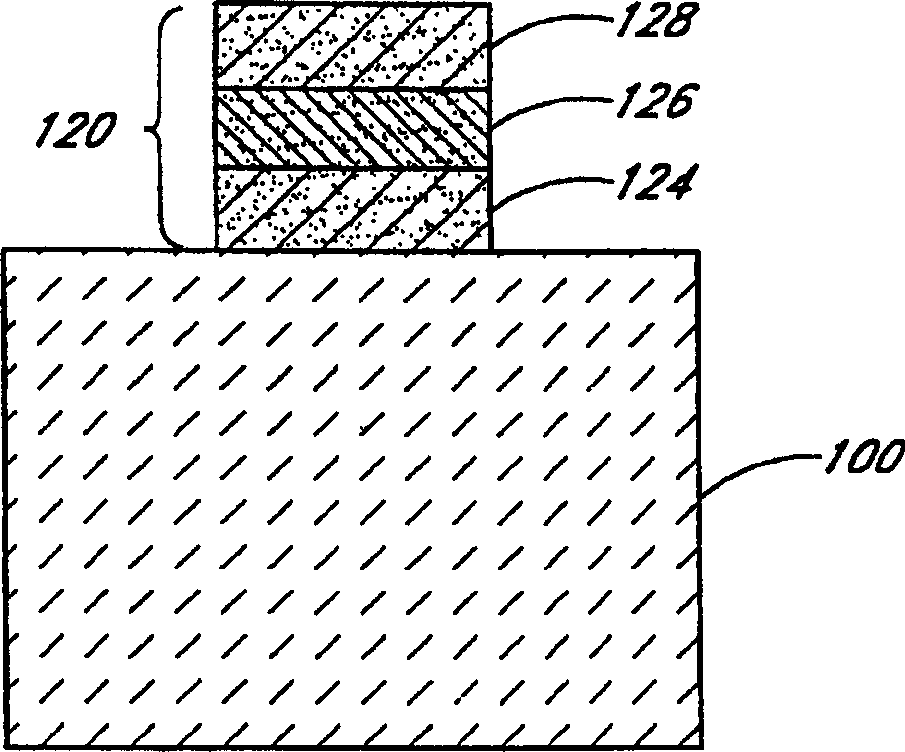

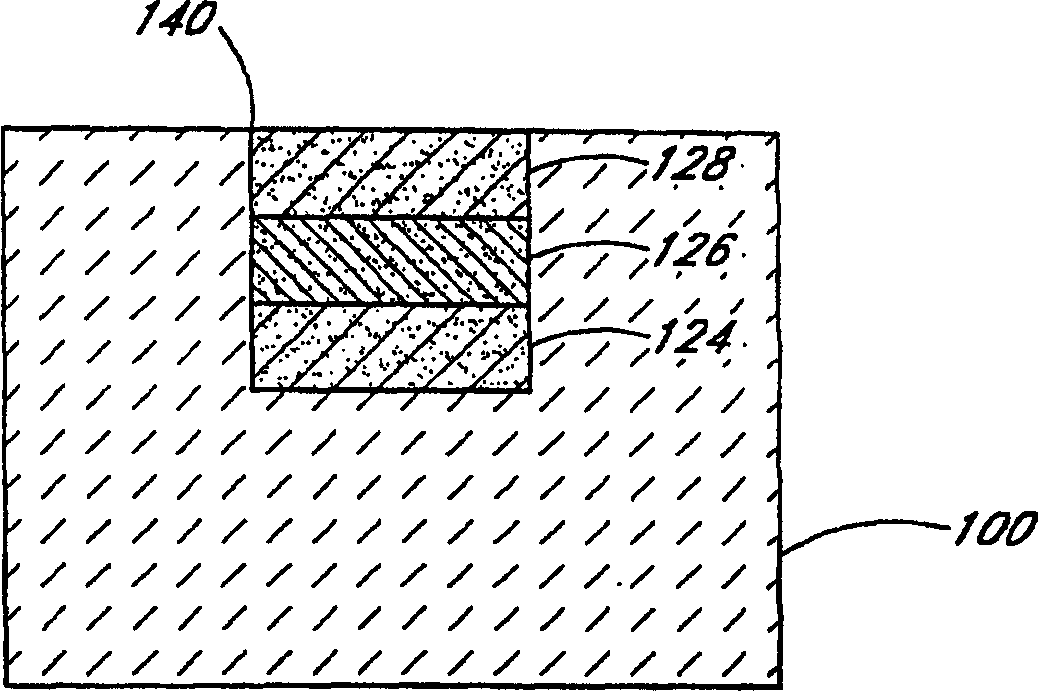

[0014] Such as figure 1 As mentioned above, the integrated planar Bragg grating includes a substrate 100 and a planar waveguide 120 . The substrate 100 includes a negative expansion material, that is, the substrate has a negative coefficient of thermal expansion. Preferably, the top surface of substrate 100 is polished, which includes a glass-ceramic material, such as lithium aluminum silicate (eg, β-eucryptite). Substrate 100 preferably comprises an amorphous material. Waveguide 120 is formed on substrate 100 by alternately depositing material on the substrate and reducing stress in the deposited material. In the disclosed preferred embodiment, the waveguide includes a cladding 124 formed by depositing a series of thin layers on a substrate. For example, a quartz film with a thickness of 0.1 micron may be deposited on the substrate 100, and then the stress in the deposited film may be reduced through an annealing cycle. Annealing of the cladding 124 also provides a stron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com