Drum taper tool and method for side milling complex cambered centrifugal impeller using drum taper tool

A tool and curved surface technology, which is applied in the field of drum-cone cutters and side milling of complex curved surfaces using drum-cone cutters, which can solve the problems of not being able to find the machining position of the tool, demanding the direction of the tool, and not being able to twist the blade too much

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

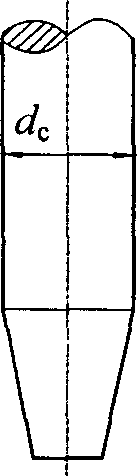

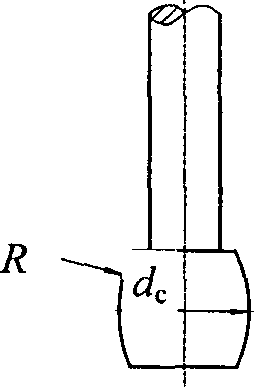

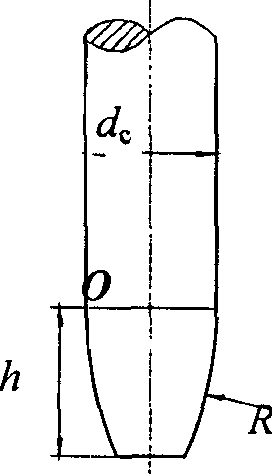

[0073] Using the spherical cutter and the drum-conical cutter respectively, the tool path generation in five-coordinate machining of centrifugal impeller blades is discussed. The blade is an arbitrary curved surface, represented by bicubic B-spline. The diameter of the spherical knife used is d c =32mm, diameter of drum cone cutter rod d c =32mm, R=70mm, h=25mm see figure 1 . The allowable residual height is 0.1mm, and the tool trajectory in blade machining is calculated for the above two tools respectively.

[0074] Calculated as Figure 8 and Figure 9 As shown, the number of trajectories for processing the blade is 16 with a drum-cone cutter, and the total length of the trajectories is 6631mm; while the number of trajectories for a spherical cutter is as many as 39, and the total length of the trajectories is 16453mm, the ratio of the two is 1: 2.5. At the same cutting speed, the processing efficiency of the drum-cone cutter is 2.5 times that of the spherical cutter....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com