Method of on line detecting acid bath components and its detecting apparatus

A technology of acid bath and composition, applied in instruments, chemical analysis by titration, non-electric variable control, etc., can solve the problems of poor measurement repeatability, lagging of measurement results, and no real-time performance, so as to improve economic benefits and supplement in real time Acid liquid, the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

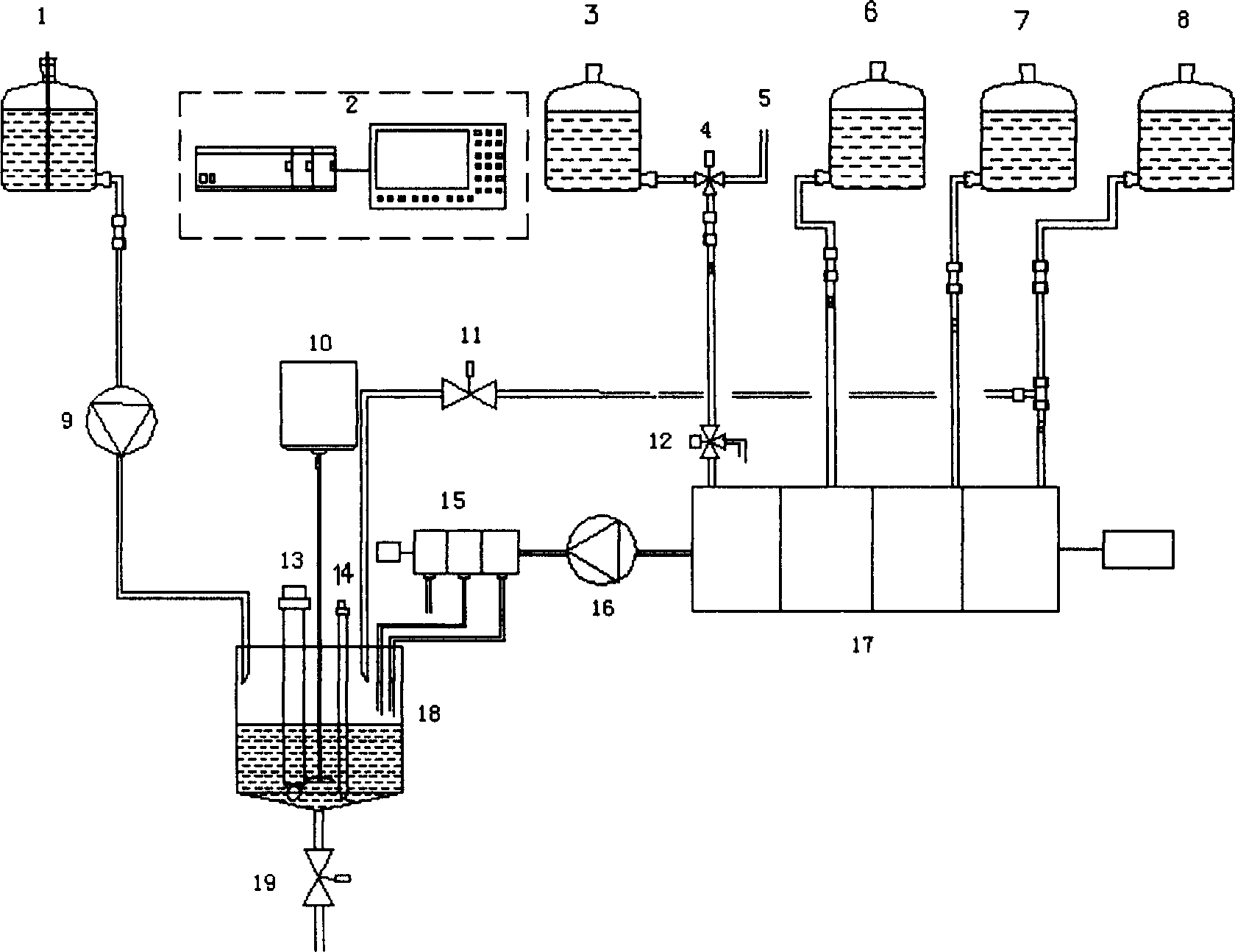

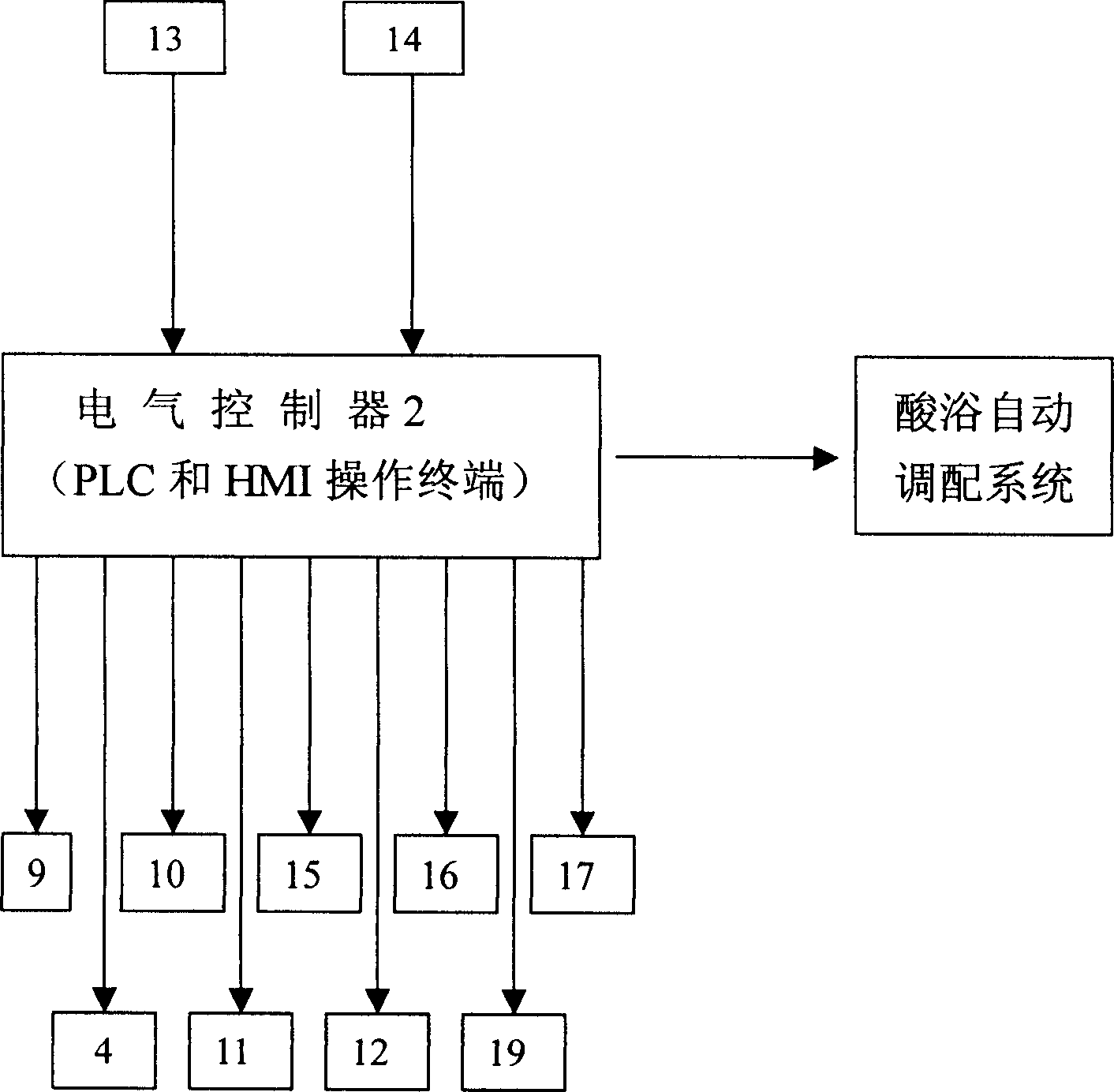

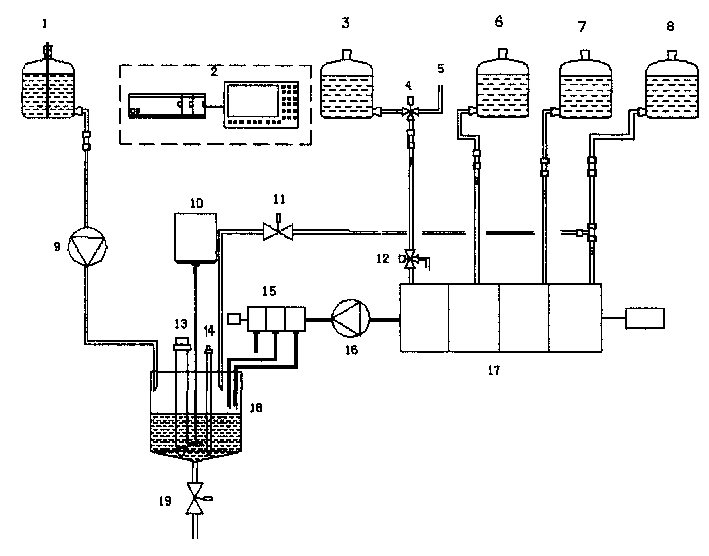

[0020] see figure 1 , there is a neutralization cuvette 18, the bottom of which is connected with a liquid discharge pipeline and a solenoid valve 19; a pH probe 13 and a Pt1000 temperature compensation probe 14 are placed in corresponding positions in the cuvette 18, and the stirrer 10 is set as a conventional stirrer The purpose of; EDTA standard solution storage tank 1 addition line (passing into reaction cup 18) has peristaltic metering pump 9; The addition line of the acid bath standard solution storage tank 3 of known concentration and the acid bath sample liquid addition pipe to be measured Road 5 is connected by solenoid valve 4, and there is solenoid valve 12 on the acid solution adding pipeline and enters an inlet of 4 inlets and 1 outlet solenoid valve 17; 1mol NaOH standard solution storage tank 6, 0.1mol NaOH standard solution storage ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com