Optical mounting substrate and optical device

A technology for installing substrates and optical devices, applied to optics, optical components, optical waveguides and light guides, etc., can solve problems such as not being installed in the correct position and weakening the advantages of costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

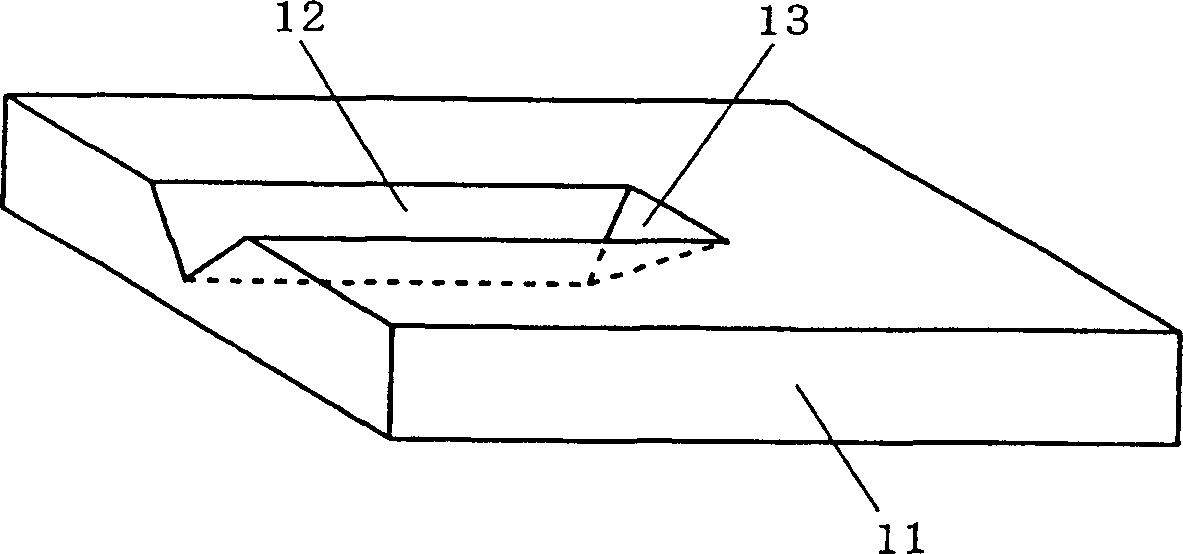

[0064] figure 1 is a perspective view showing the structure of the optical mounting substrate 11 according to the first embodiment of the present invention. Such as figure 1 As shown, a guide groove 12 for positioning an optical fiber is formed on the surface of an optical mounting base 11 , wherein a tapered surface 13 is formed adjacent to the guide groove 12 . The tapered surface 13 forms a predetermined angle with respect to the surface of the optical mounting substrate 11 .

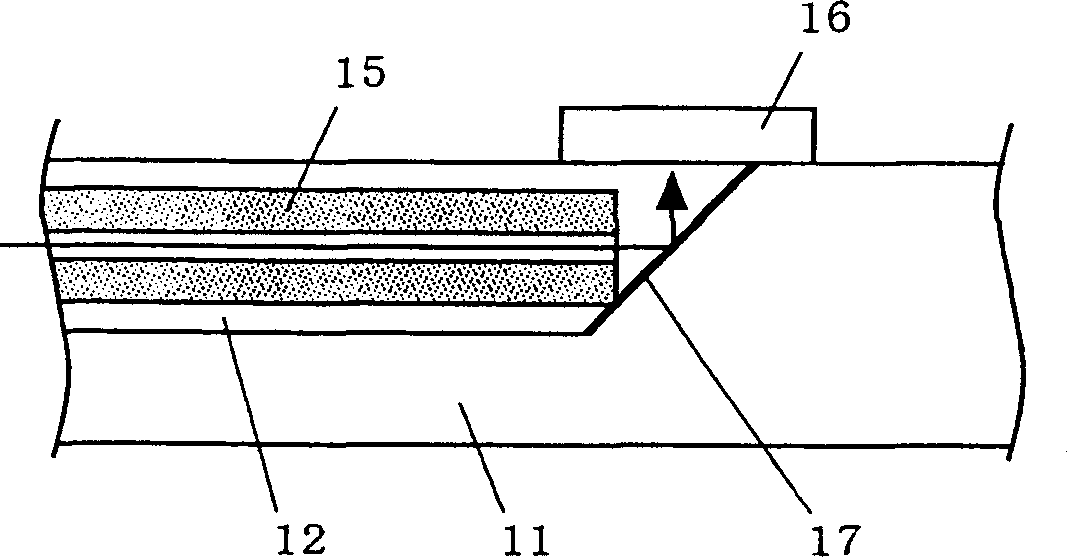

[0065] figure 2 is a cross-sectional view, which shows the use of figure 1 An optical device of an optical mounting substrate 11 on which an optical fiber 15 and a surface-receiving photodiode 16 are mounted.

[0066] Such as figure 2 As shown, the optical device structure using the optical mounting substrate 11 includes a mirror 17 formed on a tapered surface 13 formed of a thin film capable of reflecting light. The optical fiber 15 is attached in the guide groove 12 using, for example, a...

no. 2 example

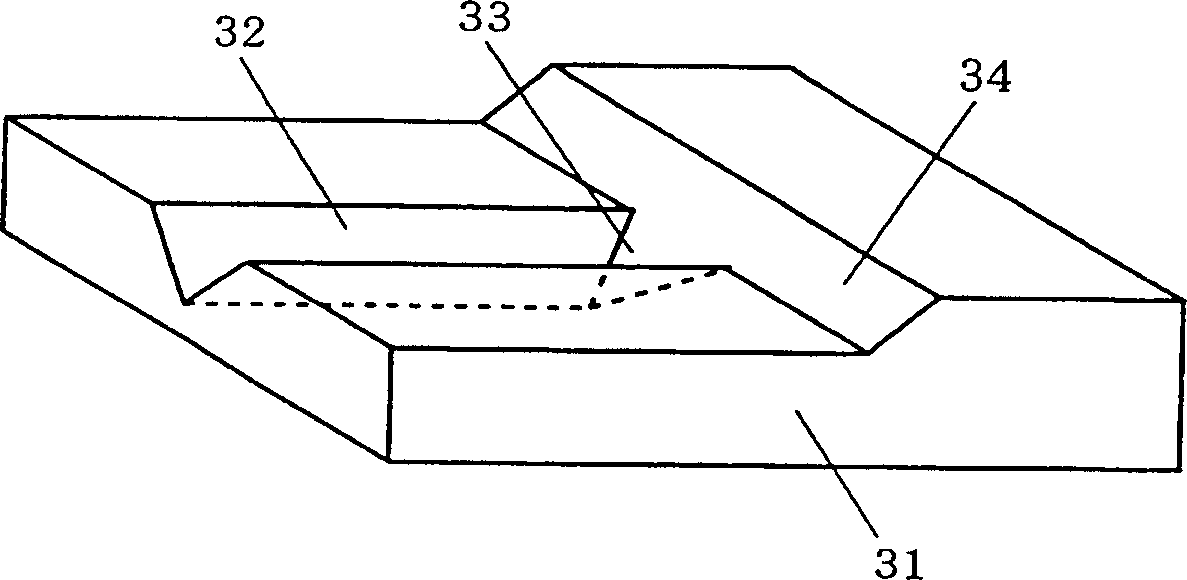

[0074] image 3 is a perspective view showing the structure of an optical mounting substrate 31 according to a second embodiment of the present invention. Such as image 3As shown, a guide groove 32 for positioning an optical fiber is formed on a surface of an optical mounting base 31, and a tapered surface 33 is formed adjacent to the guide groove 32. The tapered surface 33 forms a predetermined angle with respect to the surface of the optical mounting substrate 31 . The surface of the mounting base 31 bends at the slope 34 .

[0075] Figure 4 is a cross-sectional view, which shows the use of image 3 Shown is an optical device of an optical mounting base 31, wherein an optical fiber 35 and a surface-receiving photodiode 36 are mounted on the optical mounting base.

[0076] exist Figure 4 In the shown optical device using the optical mounting substrate 31, on the tapered surface 33, a diffraction grating 37 for diffracting light is provided. The optical fiber 35 is a...

no. 3 example

[0084] Figure 5 is a perspective view showing the structure of an optical mounting substrate 51 according to a third embodiment of the present invention. Such as Figure 5 As shown, a guide groove 52 for positioning the optical fiber is formed on the surface of the optical mounting base 51, and a predetermined tapered surface 53 is formed adjacent to the guide groove 52.

[0085] Figure 6 is a cross-sectional view, which shows the use of Figure 5 Shown is an optical device of an optical mounting base 51 on which an optical fiber 55 and a surface-emitting laser 56 are mounted.

[0086] Such as Figure 6 As shown, the optical device structure using the optical mounting substrate 51 includes a tapered surface 53 having a lens-like curvature, and a mirror 57 is formed of a film capable of reflecting light formed on the tapered surface 53 . The optical fiber 55 is attached in the guide groove 52 . The optical fiber 55 is only required to be placed in the guide groove 52, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com