Clear polycarbonate blends

A polycarbonate, transparent technology for applications in the field of transparent mixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0110] In Examples 1-4, these materials were successfully extruded using a 28 mm twin screw extruder equipped with 6 barrels, a die with 2 holes, and a medium PC screw . BCC containing 7% CS was synthesized using an interfacial approach, which has a "loose" consistency, which poses a challenge for extrusion. However, generally stable processing conditions include: screw speed 200-300 RPM, barrel temperature: room temperature / 100 / 240 / 260 / 260 / 260°C. at 5 # The vacuum center of the cylinder draws a vacuum. The melt temperature at the die was determined to be 282-285°C using a melt probe. Material was processed at 20 lb / h and 60-65% torque.

[0111] In Examples 1-4, SEM analysis was used to determine the miscibility of BCC with 1) LEXAN SP or "SP" produced by GENERAL ELECTRIC COMPANY, ie containing about 9 mol% A copolycarbonate of DDDA residues and about 91 mol % of BPA residues, and was determined for miscibility with 2) a homopolycarbonate containing BPA residues, hereinaf...

Embodiment 5-13

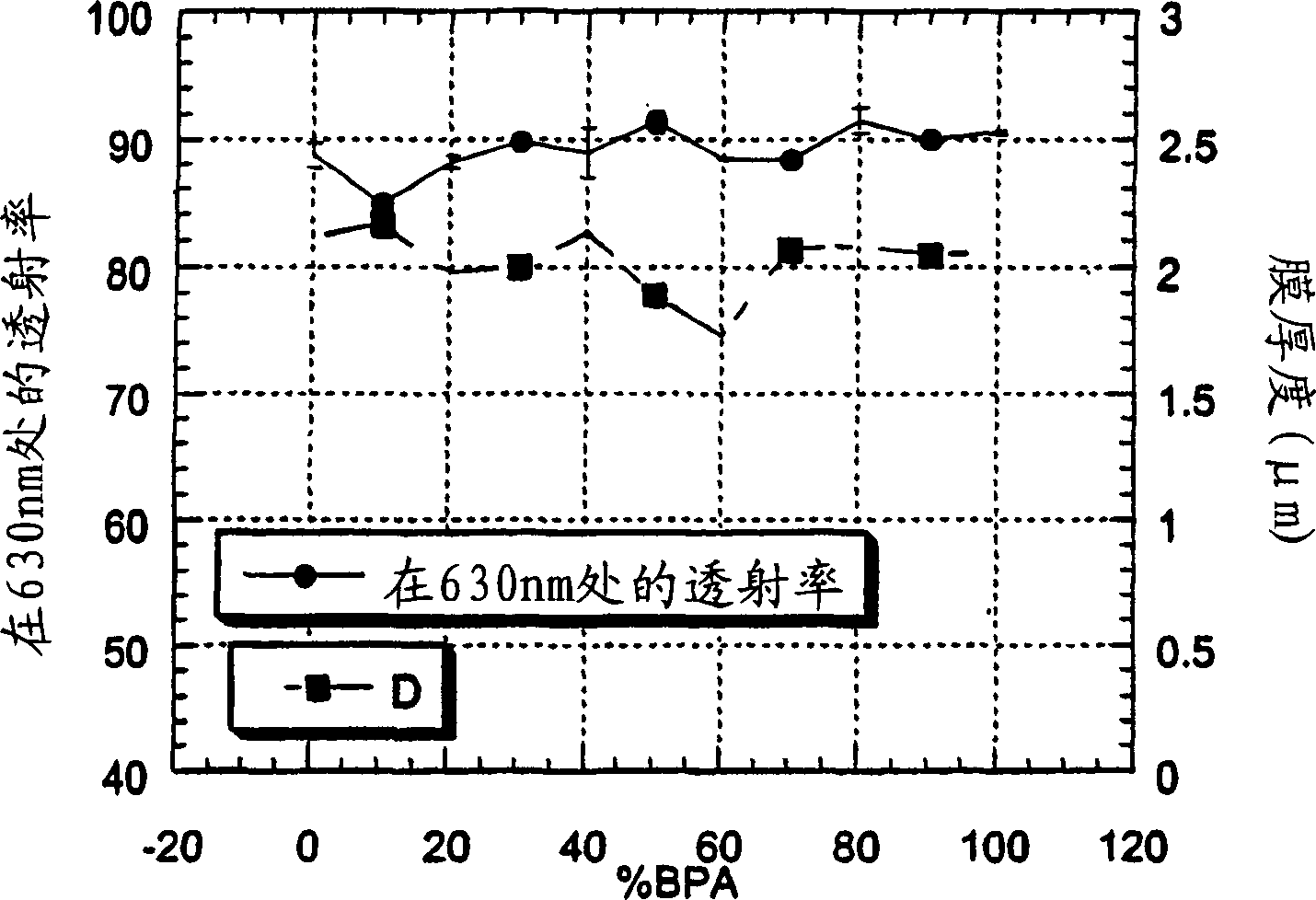

[0118] In Examples 5-13, BCC homopolymer and BPA polycarbonate, i.e. PC105 or PC120 produced by General Electric Company, were pre-mixed, or added simultaneously to a 28mm WP extruder, which had a Medium PC screw, extrusion at barrel temperature from about 260°C to about 280°C. In these examples, no catalyst was used. The pellets obtained were then poured into a 2 inch x 21 / 8 inch plaque for molding. The transmittance was measured at 630 nm using an HP CHEMSTATION UV-VIS spectrophotometer. As shown in the transmittance data below, no phase separation was observed. Example 6 is a comparative example.

[0119] Example

[0120] In Examples 14-17, the miscibility of BCC with BPA polycarbonate was further observed. The BCC polymer and BPA polycarbonate - made by General Electric under the designation PC120 - were pre-blended and fed into a 28mm WP extruder with a medium PC screw at barrel temperature Extrusion at about 260°C to about 280°C. The amount of catalyst (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com