Clear polycarbonate blends

A polycarbonate, transparent technology for transparent mixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0112] In Examples 1-4, these materials were successfully extruded using a 28 mm twin screw extruder equipped with 6 barrels, a die with 2 holes, and a medium PC screw . BCC containing 7% CS was synthesized using an interfacial approach, which has a "loose" consistency, which poses a challenge for extrusion. However, generally stable processing conditions include: screw speed 200-300RPM, barrel temperature: room temperature / 100 / 240 / 260 / 260 / 260°C. Vacuum on the vacuum center located in the 5# cylinder. The melt temperature at the die was determined to be 282-285°C using a melt probe. Material was processed at 20 lb / h and 60-65% torque.

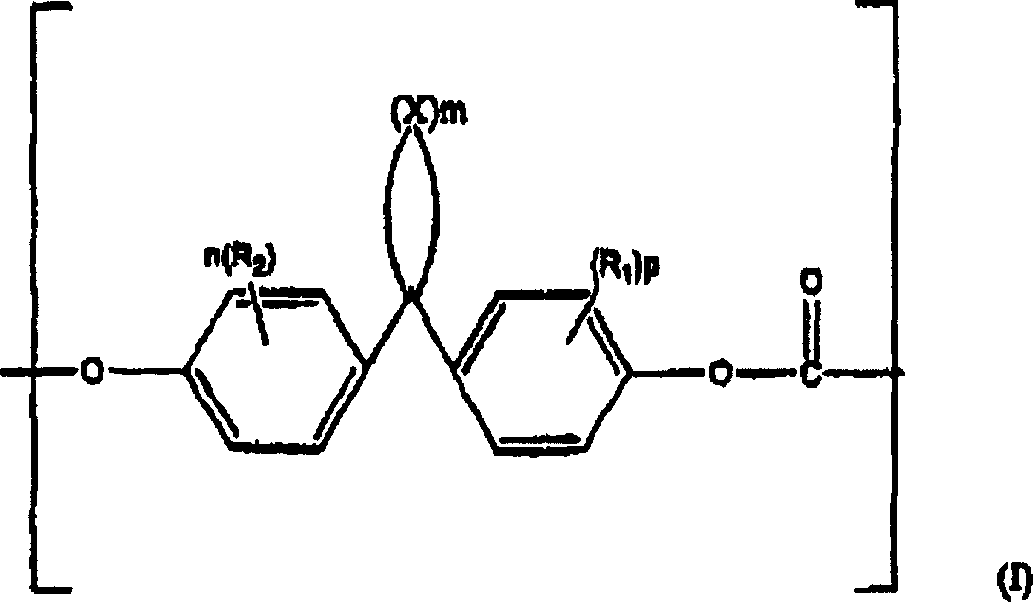

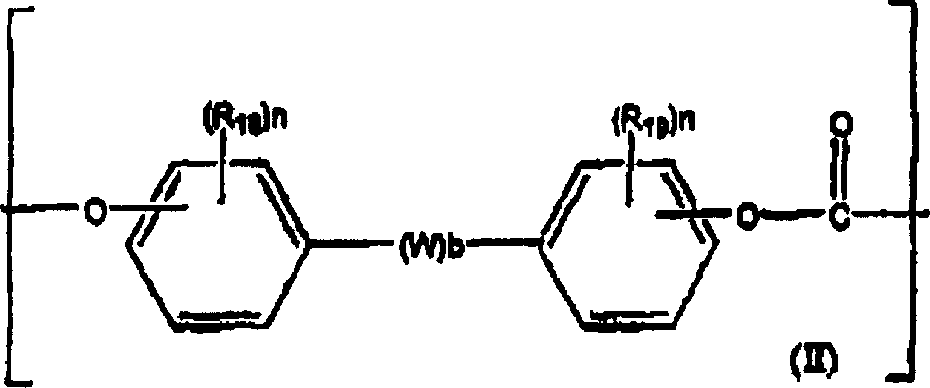

[0113] In Examples 1-4, SEM analysis was used to determine the miscibility of BCC with 1) LEXAN SP or "SP" produced by GENERAL ELECTRIC COMPANY, ie containing about 9 mol% A copolycarbonate of DDDA residues and about 91 mol % of BPA residues, and was determined for miscibility with 2) a homopolycarbonate containing BPA residues, hereinafter...

Embodiment 5-13

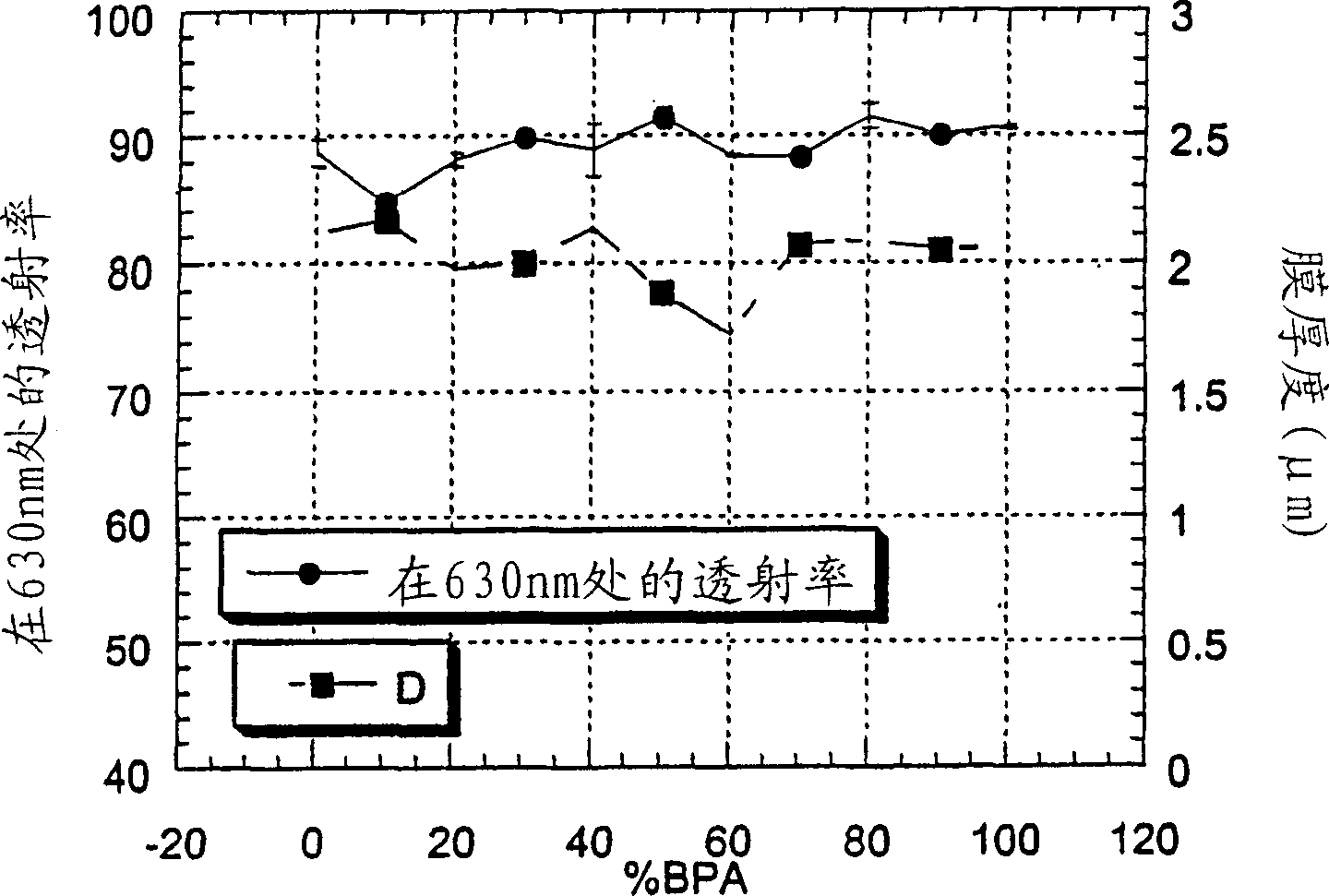

[0124] In Examples 5-13, BCC homopolymer and BPA polycarbonate, i.e. PC105 or PC120 produced by General Electric Company, were pre-mixed, or added simultaneously to a 28mm WP extruder, which had a Medium PC screw, extrusion at barrel temperature from about 260°C to about 280°C. In these examples, no catalyst was used. The pellets obtained were then poured into a 2 inch by 2 1 / 8 inch plaque for molding. The transmittance was measured at 630 nm using an HP CHEMSTATION UV-VIS spectrophotometer. As shown in the transmittance data below, no phase separation was observed. Example 6 is a comparative example.

[0125] Example

Embodiment 14-17

[0127] In Examples 14-17, the miscibility of BCC with BPA polycarbonate was further observed. The BCC polymer and BPA polycarbonate - made by General Electric under the designation PC120 - were pre-blended and fed into a 28mm WP extruder with a medium PC screw at barrel temperature Extrusion at about 260°C to about 280°C. The amount of catalyst (tetrabutyltetraphenyl borate) used is from about 0 to about 300 ppm. GPC was used to observe the efficiency of the catalyst in reducing molecular weight by hydrolysis. C 13 NMR indicated that very little transesterification occurred during the residence time in the extruder. The pellets obtained were subsequently injection molded into stretched rods. The transmittance was measured at 630 nm using an HP CHEMSTATION UV-VIS spectrophotometer. No phase separation was seen, which is evident from the high transmittance data.

[0128] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com